Method for treating waste automobile tail gas catalyst through pyrogenic attack

A technology for the treatment of automobile exhaust and pyrolysis, which is applied in chemical instruments and methods, separation methods, sustainable waste treatment, etc., to achieve the effects of excellent production environment, large processing capacity and short process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

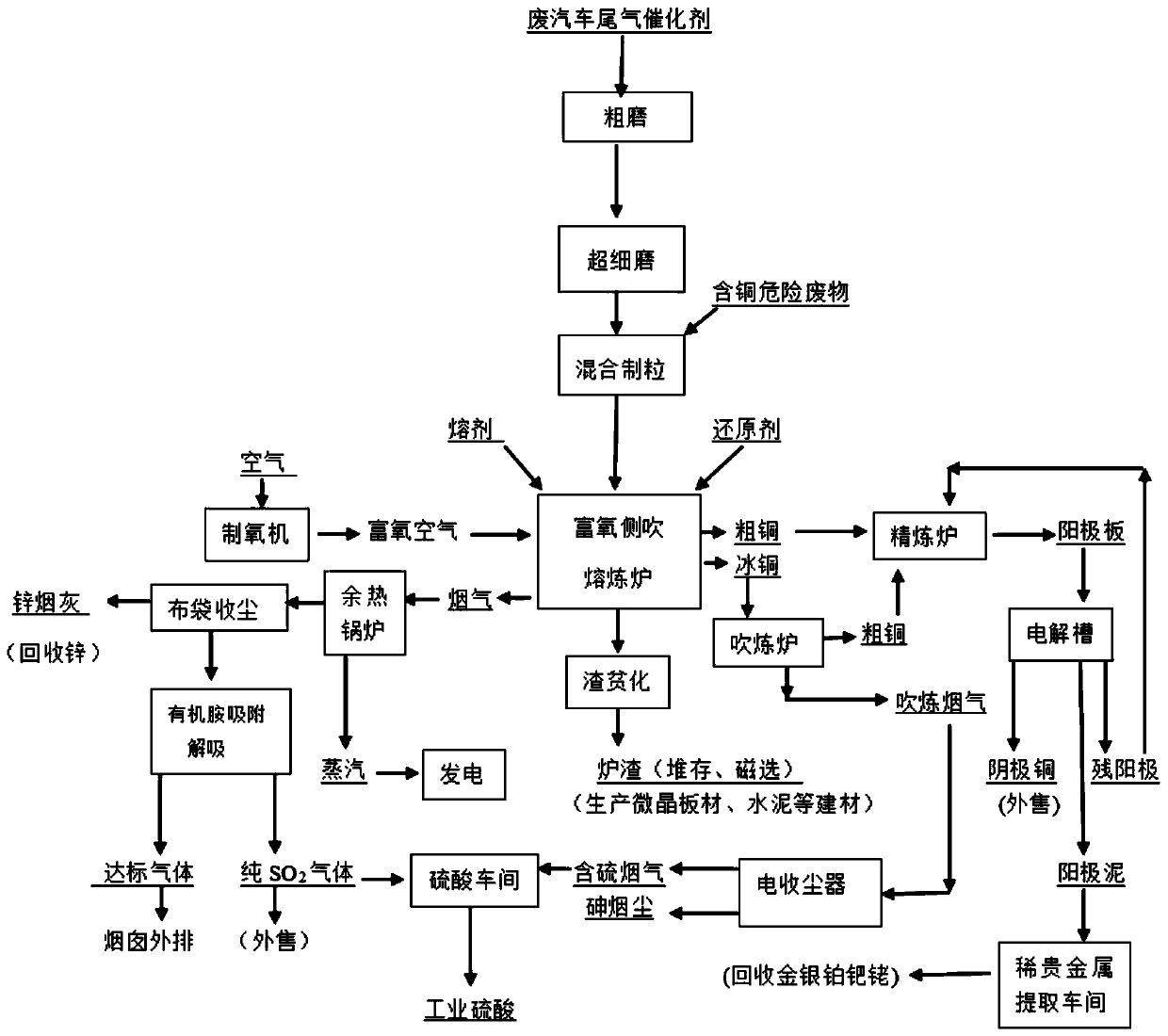

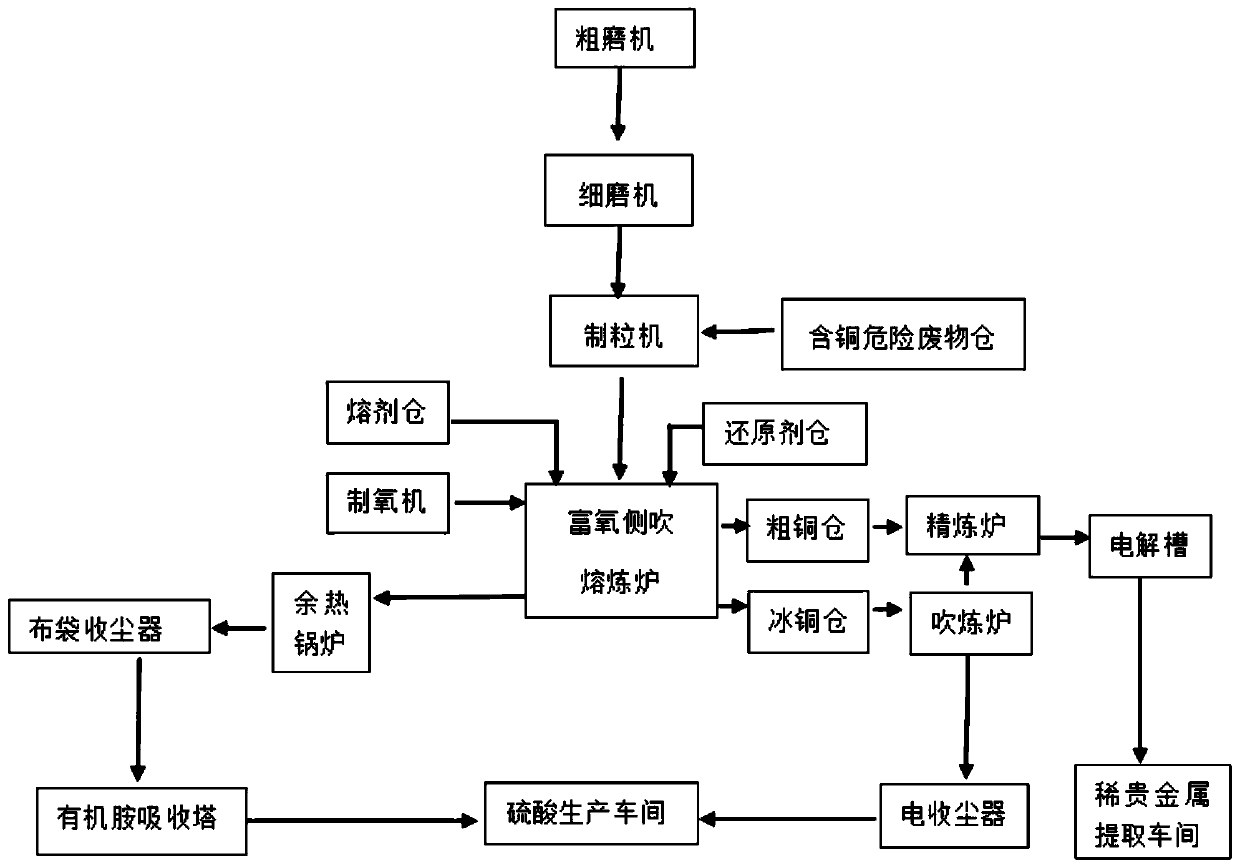

[0042] A method for pyroprocessing waste automobile exhaust catalysts, such as figure 1 Shown is the process flow diagram of the present embodiment, and described processing method comprises the steps:

[0043] (1) Coarse grinding: Coarsely and finely grind the spent catalyst to expose rare and precious metals and facilitate rapid reaction. Firstly, the used waste automobile exhaust catalyst is coarsely ground with a coarse grinder, and the coarse grinder is a sand mill, and the waste automobile exhaust catalyst is mixed with water and slurried for 0.5 hours, and the liquid-solid mass ratio is controlled at 1:2.5. The temperature of the process is normal temperature 20-25° C., the medium of the rough mill is iron, the solid particle size after rough grinding is 80 mesh to 100 mesh, and the waste automobile tail gas catalyst slurry is obtained.

[0044] (2) Ultrafine grinding: pump the coarsely ground waste automobile exhaust catalyst slurry into the feeding barrel with a mort...

Embodiment 2

[0068] A method for pyroprocessing waste automobile exhaust catalysts, comprising the steps of:

[0069] (1) Coarse grinding: use a coarse grinder or a sand mill for coarse grinding of the used waste automobile exhaust catalyst, and mix the waste automobile exhaust catalyst with water to make slurry, and control the liquid-solid mass ratio at 1:2. The temperature of the method is controlled at 15-20° C., the medium of the rough mill is iron, and the solid particle size after rough grinding is 80 mesh to 100 mesh, so as to obtain the waste automobile exhaust catalyst slurry.

[0070] (2) Ultra-fine grinding: carry out the ultra-fine grinding of the waste automobile exhaust catalyst slurry after coarse grinding, pump it into the ultra-fine grinding machine with a diaphragm pump, utilize the ultra-fine grinding machine to carry out the fine grinding of material circulation, the fine grinding The temperature of the milling process is controlled at 20-30°C, the medium of the fine m...

Embodiment 3

[0079] A method for pyroprocessing waste automobile exhaust catalysts, comprising the steps of:

[0080] (1) Coarse grinding: Use a coarse grinder or a sand mill for coarse grinding of the used waste automobile exhaust catalyst, and mix the waste automobile exhaust catalyst with water to make slurry, and control the liquid-solid mass ratio at 1:3. The temperature of the method is controlled at 30-40° C., the medium of the rough mill is iron, and the solid particle size after rough grinding is 80 mesh to 100 mesh, so as to obtain the waste automobile exhaust catalyst slurry.

[0081] (2) Ultra-fine grinding: carry out the ultra-fine grinding of the waste automobile exhaust catalyst slurry after coarse grinding, pump it into the ultra-fine grinding machine with a diaphragm pump, utilize the ultra-fine grinding machine to carry out the fine grinding of material circulation, the fine grinding The temperature of the grinding process is controlled at 30-40°C, the medium of the fine ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap