Composite essential oil microcapsule preparation for preventing and treating banana wilt and preparation method thereof

A technology of compound essential oils and preparations, applied in botany equipment and methods, biocides, fungicides, etc., can solve the problems of single function, banana fusarium wilt drug resistance damage, etc., and achieve the effect of simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

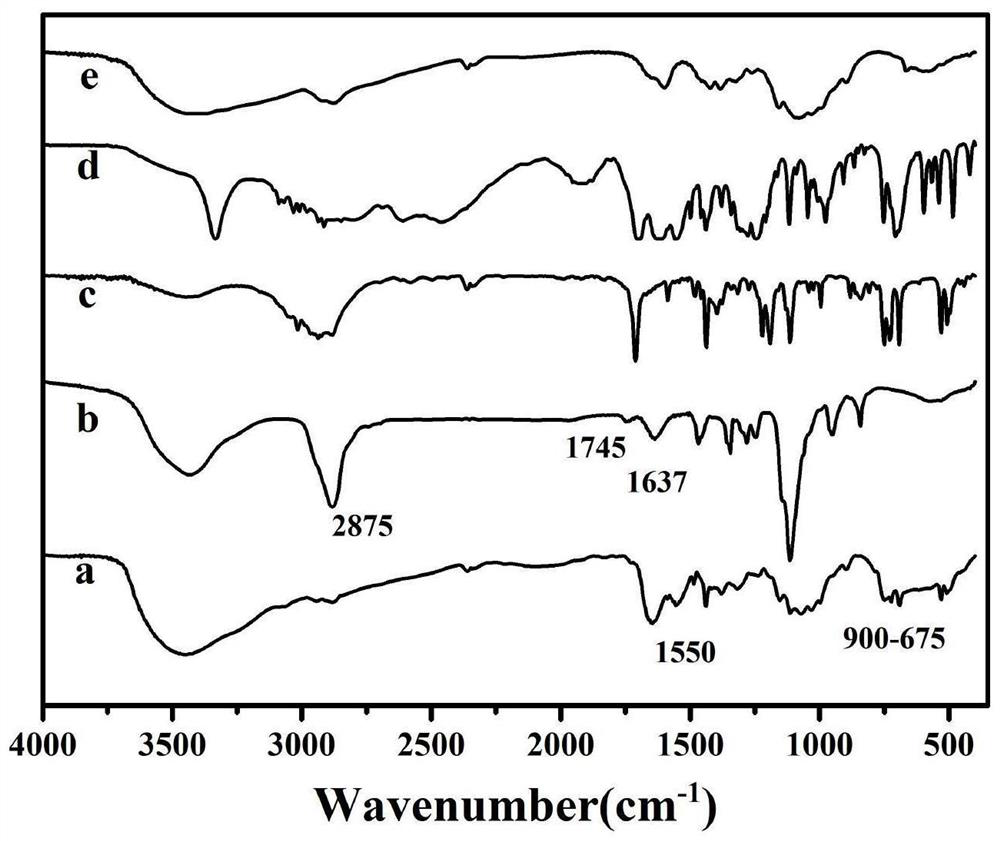

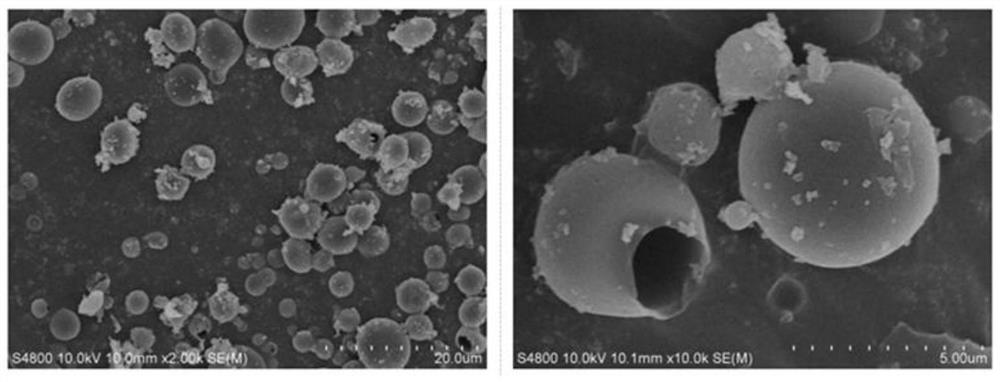

[0054] Embodiment 1 eucalyptus oil / citronella oil composite essential oil microcapsule preparation

[0055] (1) Amphiphilic quaternary phosphonium chitosan derivatives

[0056] At room temperature, 0.270 g of activator 1-hydroxy-benzotriazole (HOBT) was added dropwise to 50 mL of chitosan (CS) with a concentration of 2.0 mg / mL (viscosity-average molecular weight of 2.5×10 3 , degree of deacetylation ≥ 90%) in aqueous acetic acid solution, under normal temperature, avoid light and stir overnight to obtain a colorless and transparent homogeneous solution CS-HOBT, then mix 2.659g (4-carboxybutyl) triphenylphosphine bromide and 2.300g The 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide (EDC) was added to the CS-HOBT reaction liquid, reacted at 25°C for 24h, and the obtained reaction product was treated with a 3000Da dialysis bag Dialyzed with deionized water for 3 days, and finally freeze-dried to obtain the product quaternary phosphonium chitosan.

[0057] 0.085 g of quaternary p...

Embodiment 2

[0063] Example 2 tea tree oil / cinnamon oil composite essential oil microcapsule preparation

[0064] (1) Amphiphilic quaternary phosphonium chitosan derivatives

[0065] At room temperature, 0.270 g of activator benzotriazole-N,N,N',N'-tetramethyluronium hexafluorophosphate (HBTU) was added dropwise to 50 mL of chitosan with a concentration of 1.0 mg / mL Sugar (CS) (viscosity average molecular weight is 1.5×10 5 , degree of deacetylation ≥ 90%) in aqueous acetic acid solution, under normal temperature, avoid light and stir overnight to obtain a colorless and transparent homogeneous solution CS-HBTU, then mix 2.659g (4-carboxybutyl) triphenylphosphine bromide and 2.300g The dicyclohexylcarbodiimide (DCC) was added into the CS-HBTU reaction solution, reacted at 30°C for 12h, and the obtained reaction product was dialyzed with deionized water for 3 days with a 151000Da dialysis bag, and finally freeze-dried to obtain the product quarter Phosphonate chitosan.

[0066] Stir 0.085...

Embodiment 3

[0072] Example 3 rosemary oil / clove oil / tea tree oil composite essential oil microcapsule preparation

[0073] (1) Amphiphilic quaternary phosphonium chitosan derivatives

[0074] Add 0.270 g of the activator O-benzotriazole-N,N,N',N'-tetramethyluronium tetrafluoroboric acid (TBTU) dropwise to 50 mL of the shell at a concentration of 2.0 mg / mL at room temperature Polysaccharide (CS) (viscosity average molecular weight is 3.0×10 3 , degree of deacetylation ≥ 90%) in aqueous acetic acid solution, under normal temperature, avoid light and stir overnight to obtain a colorless and transparent homogeneous solution CS-TBTU, then mix 2.659g (4-carboxybutyl) triphenylphosphine bromide and 2.300g The diisopropylcarbodiimide (DIC) was added into the CS-TBTU reaction solution, reacted at 25°C for 36h, and the obtained reaction product was dialyzed with deionized water for 3 days with a 3500Da dialysis bag, and finally freeze-dried to obtain the product Quaternary phosphonium chitosan. ...

PUM

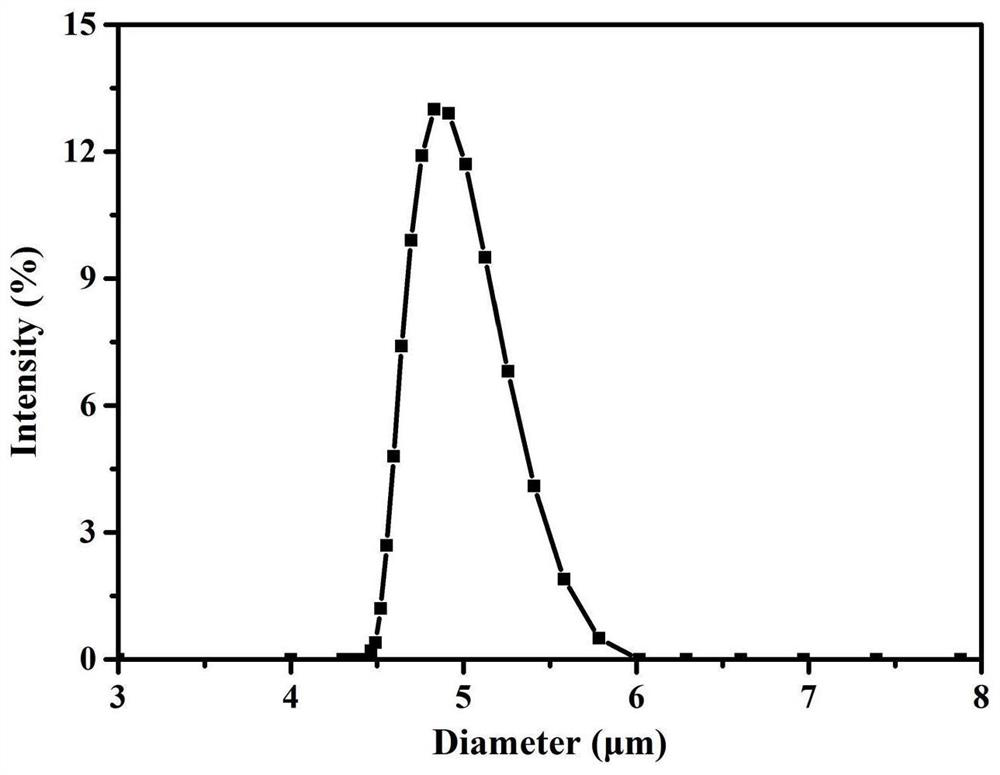

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com