Electroless plating solution for Ni-Sn-P alloy plating layer, and electroless plating layer

A technology of chemical plating solution and alloy coating, which is applied in the field of chemical plating, can solve problems such as the instability of formula plating solution, and achieve the effects of convenient preparation, stable deposition rate, and avoidance of failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

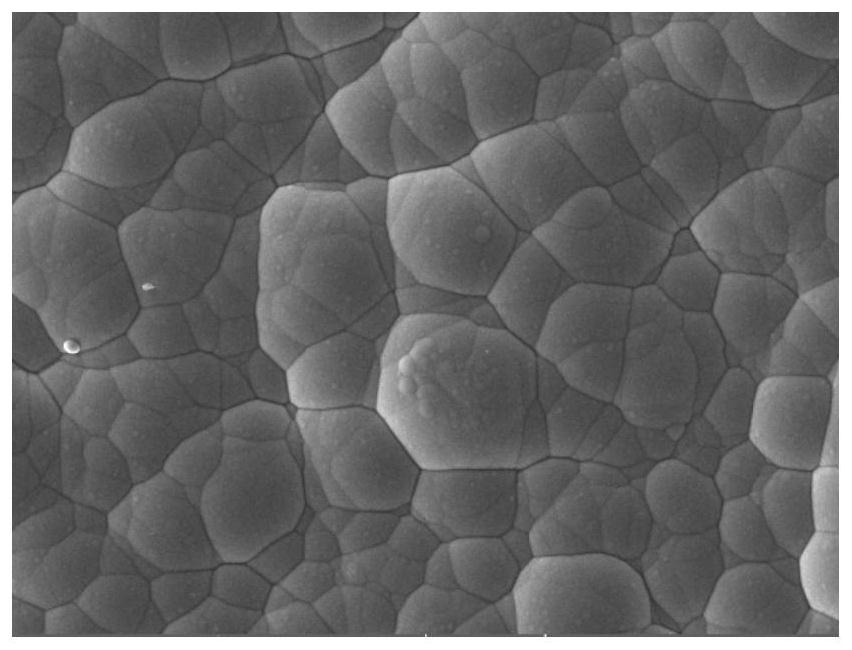

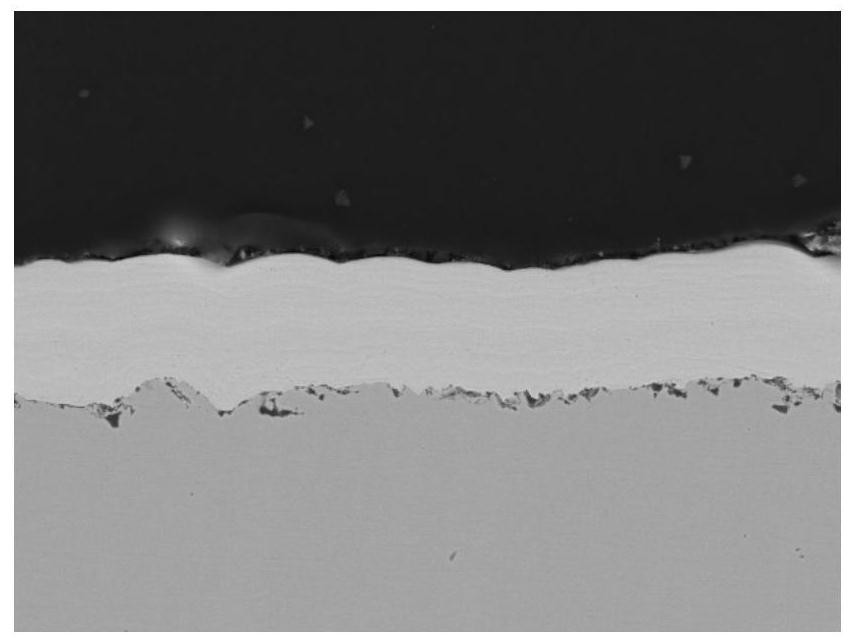

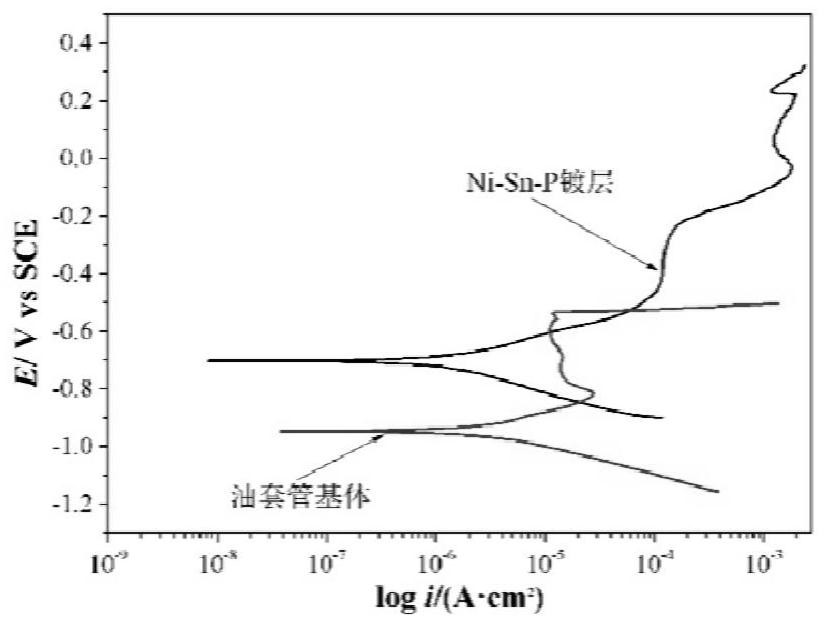

Image

Examples

Embodiment 1

[0041] A kind of electroless plating bath of Ni-Sn-P alloy coating, the total volume of electroless plating bath is 1L meter, and composition is as follows:

[0042] 35g NiCl 2 .6H 2 O, 12g Na 2 SnO 3, 24 g NaH 2 PO 2 , 113g composite complexing agent, 6.9mg composite stabilizer, 8g accelerator, 1.3g NaOH, the balance is water;

[0043] Wherein, when configuring the plating solution, first dissolve the sodium stannate completely in a 6% NaOH solution at 90°C, then cool it to room temperature and mix it with other solutions to prevent the sodium stannate from being hydrolyzed to form a water-insoluble hydroxide. Tin thereby reducing the effective concentration of tin salts in the bath.

[0044] Among them, by weight percentage, the composite complexing agent components are: sodium citrate 61.9%, lactic acid 29.2%, triethanolamine 8.9%; composite stabilizer components are: thiourea 4.3%, ceric sulfate 36.2%, cis-butyl Acenoic acid 59.5%; Accelerator is glycine.

[0045] ...

Embodiment 2

[0063] A kind of electroless plating bath of Ni-Sn-P alloy coating, the total volume of electroless plating bath is 1L meter, and composition is as follows:

[0064] 30g NiCl 2 .6H 2 O, 8g Na 2 SnO 3 , 20g NaH 2 PO 2 , 110g composite complexing agent, 6.2mg composite stabilizer, 5g accelerator, 1.4g NaOH, and the balance is water;

[0065] Among them, when configuring the plating solution, first dissolve the sodium stannate completely in a 15% NaOH solution at 90°C, then cool it to room temperature and mix it with other solutions to prevent the sodium stannate from being hydrolyzed to form insoluble hydrogen Tin oxide thereby reduces the effective concentration of tin salts in the bath.

[0066] Among them, by weight percentage, the composite complexing agent components are: sodium citrate 61.9%, lactic acid 29.2%, triethanolamine 8.9%; composite stabilizer components are: thiourea 4.3%, ceric sulfate 36.2%, cis-butyl The olefinic acid is 59.5%; the accelerator is glyci...

Embodiment 3

[0069] A kind of electroless plating bath of Ni-Sn-P alloy coating, the total volume of electroless plating bath is 1L meter, and composition is as follows:

[0070] 50g NiCl 2 .6H 2 O, 14g Na 2 SnO 3 , 30g NaH 2 PO 2 , 120g composite complexing agent, 7.4mg composite stabilizer, 10g accelerator, 1.5g NaOH, the balance is water;

[0071] Among them, when configuring the plating solution, first dissolve the sodium stannate completely in a 20% NaOH solution at 90°C, then cool it to room temperature and mix it with other solutions to prevent the sodium stannate from being hydrolyzed to form insoluble hydrogen Tin oxide thereby reduces the effective concentration of tin salts in the bath.

[0072] Among them, by weight percentage, the composite complexing agent components are: sodium citrate 61.9%, lactic acid 29.2%, triethanolamine 8.9%; composite stabilizer components are: thiourea 4.3%, ceric sulfate 36.2%, cis-butyl Acenoic acid 59.5%; Accelerator is glycine.

[0073] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Self-corrosion current density | aaaaa | aaaaa |

| Self-corrosion current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap