Beer yeast capable of producing beer with low acetaldehyde content, and domestication method of beer yeast

A brewer's yeast, low acetaldehyde technology, applied in the direction of using microorganisms, microorganism-based methods, biochemical equipment and methods, etc., can solve problems such as poor acetaldehyde content reduction effect, poor strain stability, etc. The effect of enhancing the average activity and improving the metabolic capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] The present embodiment provides a brewer's yeast domestication method capable of producing beer with low acetaldehyde content, and its specific method is as follows:

[0060] ·Cultivation medium and its formula:

[0061] Ethanol-YNB liquid medium ( / L), the formula is: ethanol 10-20g, ammonium sulfate 5g, biotin 2μg, calcium pantothenate 400μg, folic acid 2μg, inositol 2000μg, nicotinic acid 400μg, p-aminobenzoic acid 200μg, pyridoxine hydrochloride Pyridoxine 400μg, riboflavin 200μg, thiamine hydrochloride 400μg, boric acid 500μg, copper sulfate 40μg, potassium iodide 100μg, ferric chloride 200μg, manganese sulfate 400μg, sodium molybdate 200μg, zinc sulfate 400μg, potassium dihydrogen phosphate 1g, sulfuric acid Magnesium 0.5g, sodium chloride 0.1g, calcium chloride 0.1g;

[0062] Disulfiram liquid medium ( / L), the formula is: ethanol 10-20g, 4-methylpyrazole 0.4g, disulfiram 0.2mg, ammonium sulfate 5g, biotin 2μg, calcium pantothenate 400μg, folic acid 2μg, muscle 2...

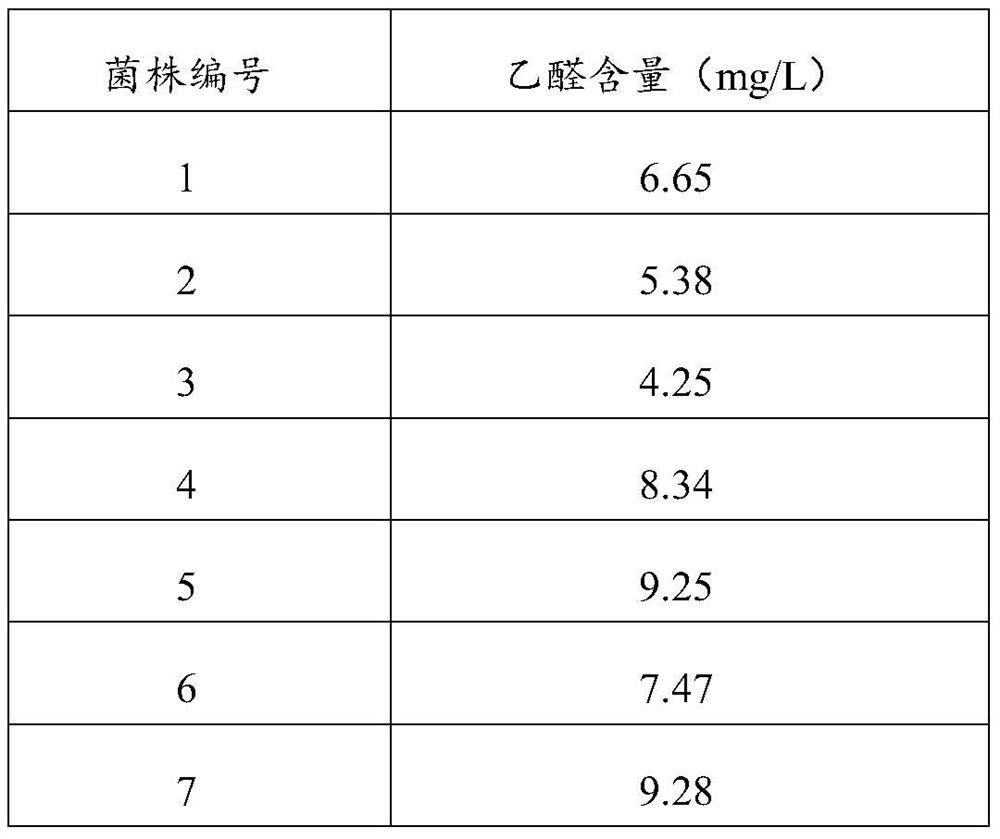

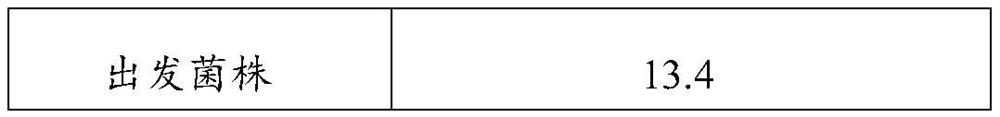

Embodiment 2

[0073] The present embodiment utilizes the bacterial strain fermentation experiment that the domestication method provided in Example 1 carries out, and its concrete steps are as follows:

[0074] (1) Pick multiple single colonies of starting strains and place them in YPD medium for static culture at 28°C for 48 hours, then centrifuge to obtain yeast sludge, wash them twice with deionized water, and inoculate them in ethanol-YNB liquid with 2% ethanol added In culture medium, OD after inoculation 600 = 0.5;

[0075] (2) Add the inoculated bacterial solution into the fully automatic high-throughput microbial droplet culture instrument, select the adaptive monitoring mode, and make the starting strain in the ethanol-YNB liquid medium with 2% ethanol without any repressor After culturing for 30 hours, droplets were generated;

[0076] (3) Transfer the generated droplets into the ethanol-YNB liquid medium supplemented with 0.1g / L 4-methylpyrazole, and automatically subculture fo...

Embodiment 3

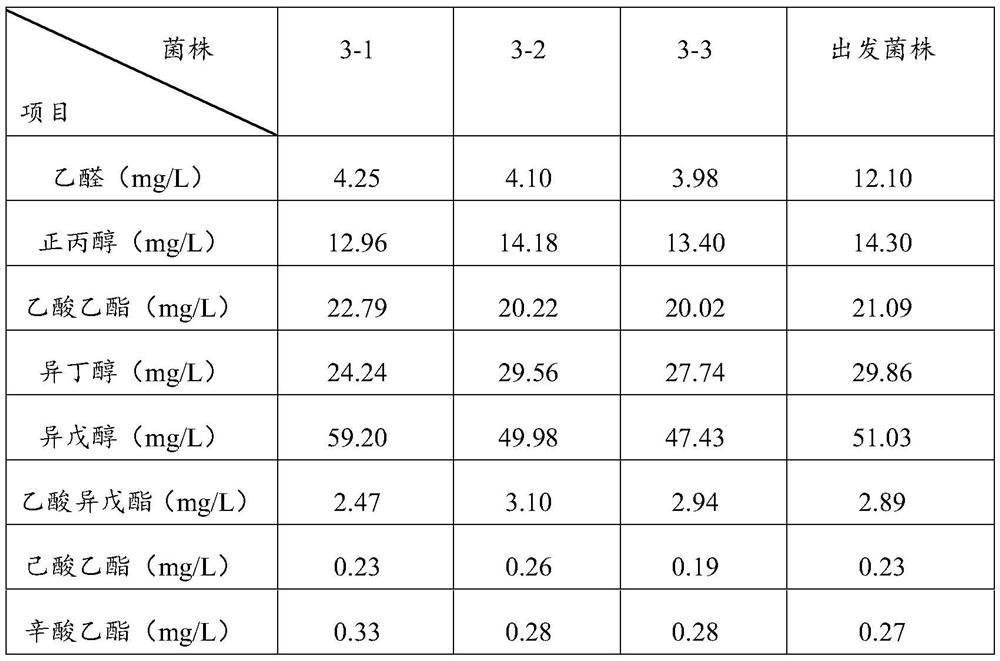

[0088] The present embodiment carries out fermentation performance stability experiment to selected bacterial strain on the basis of embodiment 2, and its specific method is as follows:

[0089] The bacterial strains screened in Example 2 were used for 10 generations of subculture in YPD liquid medium. The specific method of subculture is: use an inoculation needle to inoculate in a small test tube containing 5 mL of YPD liquid medium. After the passaging was completed, the 1st generation strain, the 5th generation strain and the 10th generation strain were subjected to fermentation experiments. The fermentation results and flavor substances are shown in Table 3.

[0090] Table 3 Fermentation results of beer yeast 1st generation strain, 5th generation strain and 10th generation strain

[0091]

[0092] The content of acetaldehyde and flavor substances of the above strains were obtained through fermentation experiments on the screened 1st generation strains, 5th generation a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com