Preparation method of high-thermal-conductivity composite material

A technology of composite materials and thermally conductive materials, which is applied in the field of preparation of high thermally conductive composite materials, can solve the problems of polymer mechanical properties, lower processing performance, poor affinity between fillers and polymer matrix, and limit the application of thermally conductive composite materials. The effect of reduced mechanical properties, superior thermal conductivity, and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

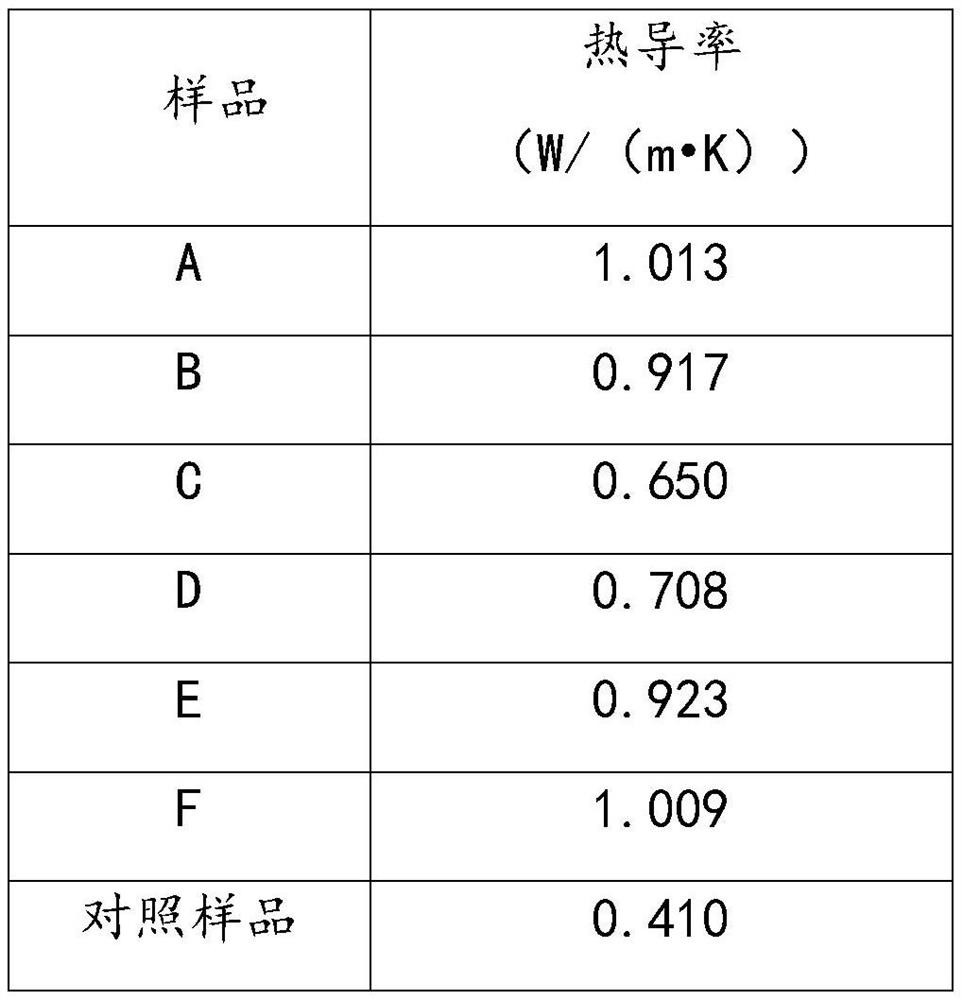

Embodiment 1

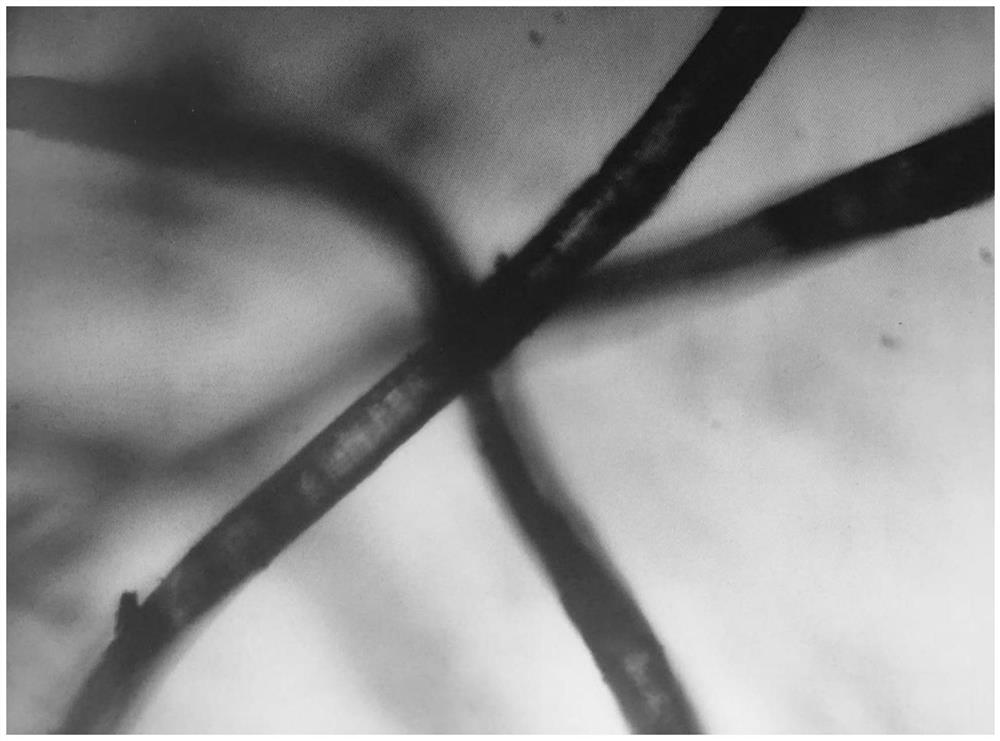

[0029] Such as figure 1 As shown, the invention provides a kind of preparation method of high thermal conductivity composite material, comprises the following steps:

[0030] 1) Proportioning according to the following components and parts by weight:

[0031] The thermally conductive material is a mixture of graphene and copper powder, including 0.4 parts of graphene and 0.1 part of copper powder;

[0032] The dispersant is a silane coupling agent, 0.8 parts;

[0033] The natural organic polymer material is starch, 2 parts;

[0034] Polymer powder is polyethylene, 100 parts;

[0035] 2) Add graphene, copper powder, silane coupling agent, starch, and polyethylene into the aqueous solution according to the ratio of step 1) and use ultrasonic dispersion for pre-dispersion treatment. After the pre-dispersion treatment, transfer it to an autoclave reactor for Heat treatment, the treatment temperature is 150°C, the pressure is 0.25MPa, and the reaction process is continuously st...

Embodiment 2

[0039] The invention provides a method for preparing a high thermal conductivity composite material, comprising the following steps:

[0040] 1) Proportioning according to the following components and parts by weight:

[0041] The thermally conductive material is a mixture of graphene and alumina, of which 0.4 parts of graphene and 0.1 parts of alumina;

[0042] The dispersant is a titanate coupling agent, 0.7 parts;

[0043] The natural organic polymer material is cyclodextrin, 1.5 parts;

[0044] Polymer powder is polyethylene, 100 parts;

[0045] 2) Add graphene, alumina, titanate coupling agent, chitosan, and polyethylene into the aqueous solution according to the ratio of step 1) and use ultrasonic dispersion for pre-dispersion treatment. After pre-dispersion treatment, transfer to autoclaved Heat treatment is carried out in the reaction kettle, the treatment temperature is 150°C, the pressure is 0.25MPa, and the reaction process is continuously stirred;

[0046] 3) F...

Embodiment 3

[0049] The invention provides a method for preparing a high thermal conductivity composite material, comprising the following steps:

[0050] 1) Proportioning according to the following components and parts by weight:

[0051] The thermal conductive material is a mixture of carbon microspheres and silicon carbide, wherein 0.2 parts of carbon microspheres and 0.2 parts of silicon carbide;

[0052] The dispersant is an aluminate coupling agent, 1.5 parts;

[0053] The natural organic polymer material is cellulose, 2.5 parts;

[0054] Polymer powder is polyethylene, 100 parts;

[0055]2) Add carbon microspheres, silicon carbide, aluminate coupling agent, cellulose, and polyethylene into the aqueous solution according to the ratio of step 1), and use a sand mill to disperse for pre-dispersion treatment, and transfer after pre-dispersion treatment Carry out heat treatment in the autoclave reactor, the treatment temperature is 160°C, the pressure is 0.3MPa, and the reaction proce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com