Solvent type spraying photocuring antibacterial coating as well as preparation method and application thereof

An antibacterial coating and photocuring technology, which is applied in epoxy resin coatings, antifouling/underwater coatings, polyurea/polyurethane coatings, etc., can solve the problems of antibacterial effect failure and achieve synergistic, effective and durable antibacterial effects , the effect of improving compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] The raw materials for the preparation of the prepolymer I, in parts by weight, include: 12.9-15.4 parts of choline chloride, 18.9-25.9 parts of diisocyanate, 0.06-0.1 part of the second catalyst, and 33-41 parts of diluent; Diisocyanate is selected from at least one of isophorone diisocyanate, dicyclohexylmethane diisocyanate, toluene diisocyanate, hexamethylene diisocyanate, diphenylmethane diisocyanate; the second catalyst is selected from organic bismuth , one or more of organotin, organozinc, potassium iodide; the diluent is an acrylate reactive diluent; more preferably, the acrylate reactive diluent is selected from 1,6-hexanediol diacrylate , tripropylene glycol diacrylate, neopentyl glycol diacrylate, 1,4-butanediol diacrylate, trimethylolpropane triacrylate, pentaerythritol tetraacrylate, ethoxylated trimethylolpropane triacrylate One or more of acrylates.

[0046] The preparation method of the prepolymer I comprises the following steps: adding choline chloride...

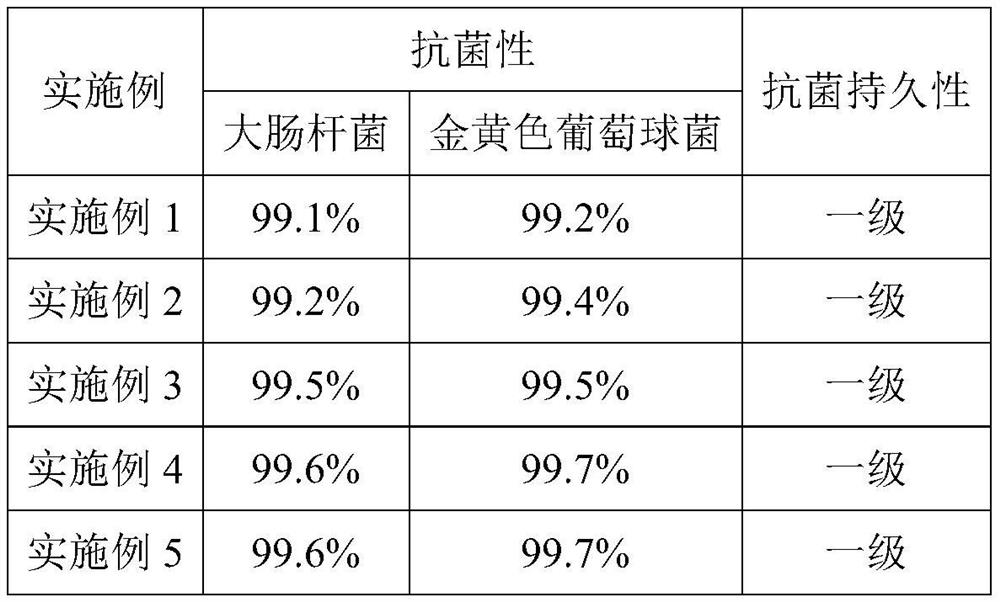

Embodiment 1

[0115] Embodiment 1 provides a kind of solvent-based spraying light-curing antibacterial coating, the preparation raw material of described antibacterial coating, by weight percentage, comprises following component: 10% butyl acetate, 20% ethyl acetate, 6% bis-trisulfite Propylene Glycol Diacrylate, 12% Trimethylolpropane Triacrylate, 20% Urethane Acrylate, 15% Epoxy Acrylate, 12% Photocurable Antimicrobial Resin, 2.5% Initiator, 0.3% Leveling Agent, 2.2% Propylene Glycol Methyl ether acetate.

[0116] The urethane acrylate is selected from allnex group EBECRYL 246; the epoxy acrylate is selected from Changxing Chemical 621A-80; the photoinitiator is selected from BASF photoinitiator Irgacure 184; the leveling agent is selected from From BYK-333 leveling agent;

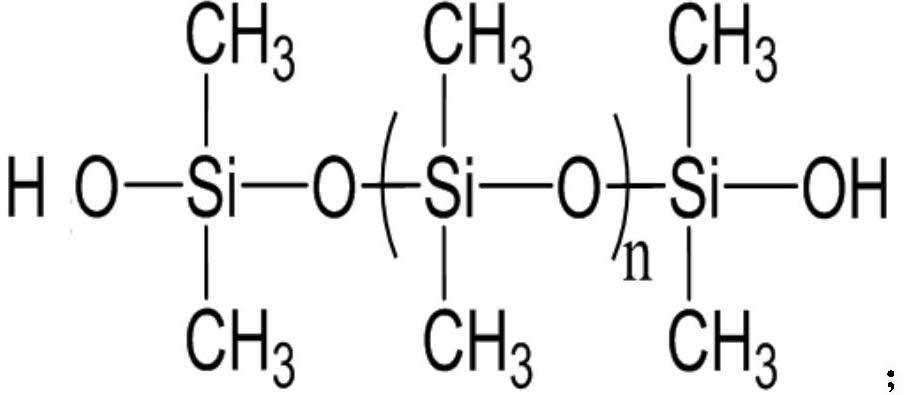

[0117] The preparation raw material of described photocurable antibacterial resin comprises: 56.7g prepolymer I, 89.4g prepolymer II, 104.2g hydroxyl-terminated polydimethylsiloxane (the number average molecular weig...

Embodiment 2

[0126] The difference between embodiment 2 and embodiment 1 is that the preparation raw material of described antibacterial paint, by weight percentage, comprises following component: 10% butyl acetate, 20% ethyl acetate, 6% tripropylene glycol diacrylate , 10% trimethylolpropane triacrylate, 19% urethane acrylate, 15% epoxy acrylate, 18% photocurable antibacterial resin, 2.5% initiator, 0.3% leveling agent, 2.2% propylene glycol methyl ether acetate .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Film thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com