A kind of chemical mechanical polishing liquid and chemical mechanical polishing method

A chemical mechanical and polishing liquid technology, applied in the direction of polishing compositions containing abrasives, grinding machine tools, metal processing equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

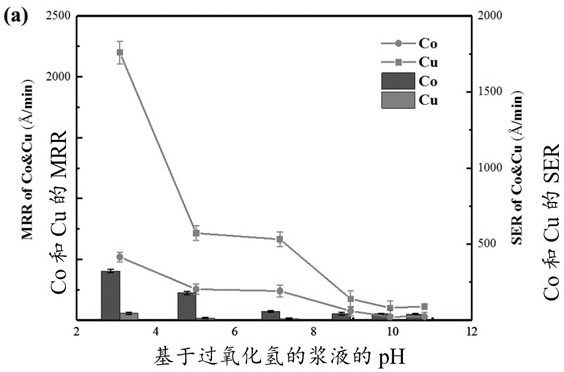

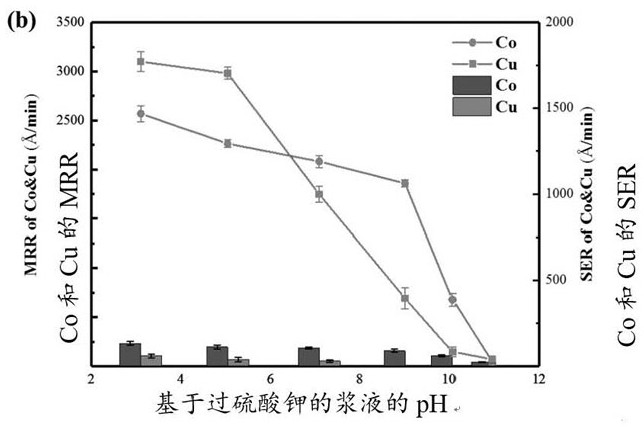

[0051] Example 1. Effect of Two Different Oxidants and pH Values on Polishing Removal Rates (MRRs) and Static Erosion Rates (SERs) of Cu / Co Interconnects

[0052] Polishing liquids having the following compositions were prepared for testing.

[0053] Polishing liquid (1) composition:

[0054] A) colloidal silicon dioxide (60nm in particle diameter, produced by Shanghai Xinanna Technology Co., Ltd.) 200g / L;

[0055] B) Oxidizing agent: potassium persulfate 2.7032g / L;

[0056] C) pH adjuster: potassium hydroxide 1g / L;

[0057] And add deionized water to 1000 mL.

[0058] Polishing liquid (2) is composed of:

[0059] A) colloidal silicon dioxide (60nm in particle diameter, produced by Shanghai Xinanna Technology Co., Ltd.) 200g / L;

[0060] B) Oxidizing agent: hydrogen peroxide 10mL;

[0061] C) pH adjuster: potassium hydroxide 1g / L;

[0062] And add deionized water to 1000 mL.

[0063] Polishing conditions:

[0064] Polisher-Universal 150Plus, temperature-25 degrees Ce...

Embodiment 2

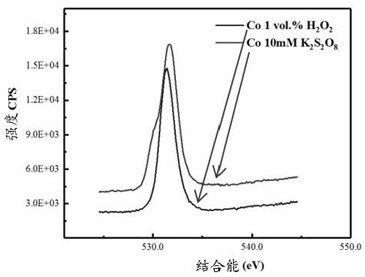

[0069] Embodiment 2. The influence of two kinds of oxidizing agents on Cu / Co surface chemical composition

[0070] Solutions having the following compositions were prepared for testing.

[0071] Composition (all weight percentages are based on the entire solution):

[0072] Solution (1) consists of:

[0073] A) Oxidizing agent: potassium persulfate 2.7032g / L;

[0074] B) pH adjuster: potassium hydroxide 1g / L;

[0075] And add deionized water to 1000 mL.

[0076] Solution (2) consists of:

[0077] A) Oxidizing agent: hydrogen peroxide 10mL;

[0078] B) pH adjuster: potassium hydroxide 1g / L;

[0079] And add deionized water to 1000 mL.

[0080] condition:

[0081] Soak the copper wafer and the cobalt wafer in the corresponding solution for 1 minute respectively, take out the nitrogen gas and blow dry, and perform measurement and characterization.

[0082] The composition of Cu / Co surface films soaked in different oxidants was investigated using X-ray photoelectron spect...

Embodiment 3

[0092] Example 3. Analysis of Cu / Co surface mechanical properties under the action of two oxidizing agents

[0093] Solutions having the following compositions were prepared for testing.

[0094] Solution (1) consists of:

[0095] A) Oxidizing agent: potassium persulfate 2.7032g / L;

[0096] B) pH adjuster: potassium hydroxide 1g / L;

[0097] And add deionized water to 1000 mL.

[0098] Solution (2) consists of:

[0099] A) Oxidizing agent: hydrogen peroxide 10mL;

[0100] B) pH adjuster: potassium hydroxide 1g / L;

[0101] And add deionized water to 1000 mL.

[0102] condition:

[0103] Soak the copper wafer and the cobalt wafer in the corresponding solution for 1 minute respectively, take out the nitrogen gas and blow dry, and perform measurement and characterization.

[0104] Figure 7 It is the SEM images of Cu and Co surfaces treated by two oxidants under the condition of pH10. It can be found from the figure that the oxidant H 2 o 2 After the treatment, there are...

PUM

| Property | Measurement | Unit |

|---|---|---|

| rotating speed | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com