A rare earth vanadate nano fluorescent labeling material and its preparation method and application

A rare earth vanadate and nano-fluorescence technology, applied in the direction of analyzing materials, material inspection products, instruments, etc., to achieve the effects of easy control, easy surface modification, and uniform size and morphology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] 1. Rare earth vanadate nano-fluorescence labeling material GdVO 4 : Preparation of 30%Eu:

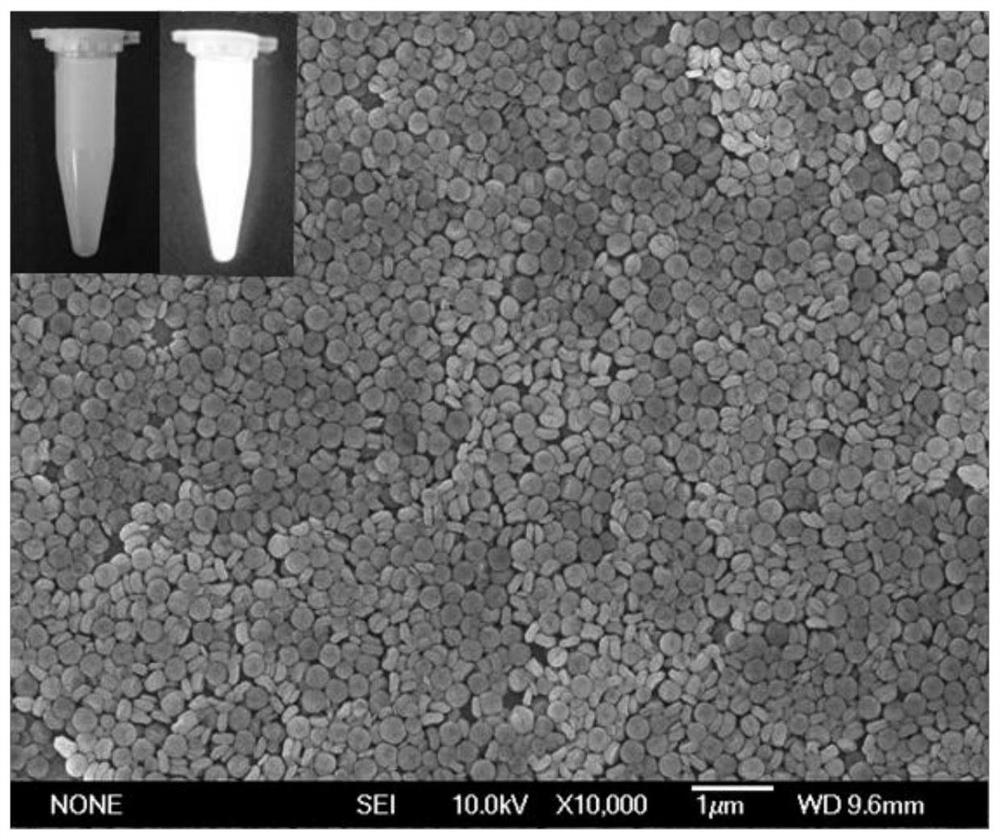

[0046] In a 50 mL round bottom flask, add 20 mL of water, 0.35 mmol of gadolinium nitrate, 0.15 mmol of europium nitrate, 2 mmol of sodium citrate, 0.5 mmol of sodium orthovanadate, feed nitrogen, react at 85°C for 24 hours, centrifuge at 10,000 rpm, Wash 3 times with distilled water and dry to obtain water-soluble GdVO with good dispersibility 4 : 30% Eu nano fluorescent labeling material. Among them, GdVO 4 as matrix, Eu 3+ For doping ions, its mole percentage is 30%.

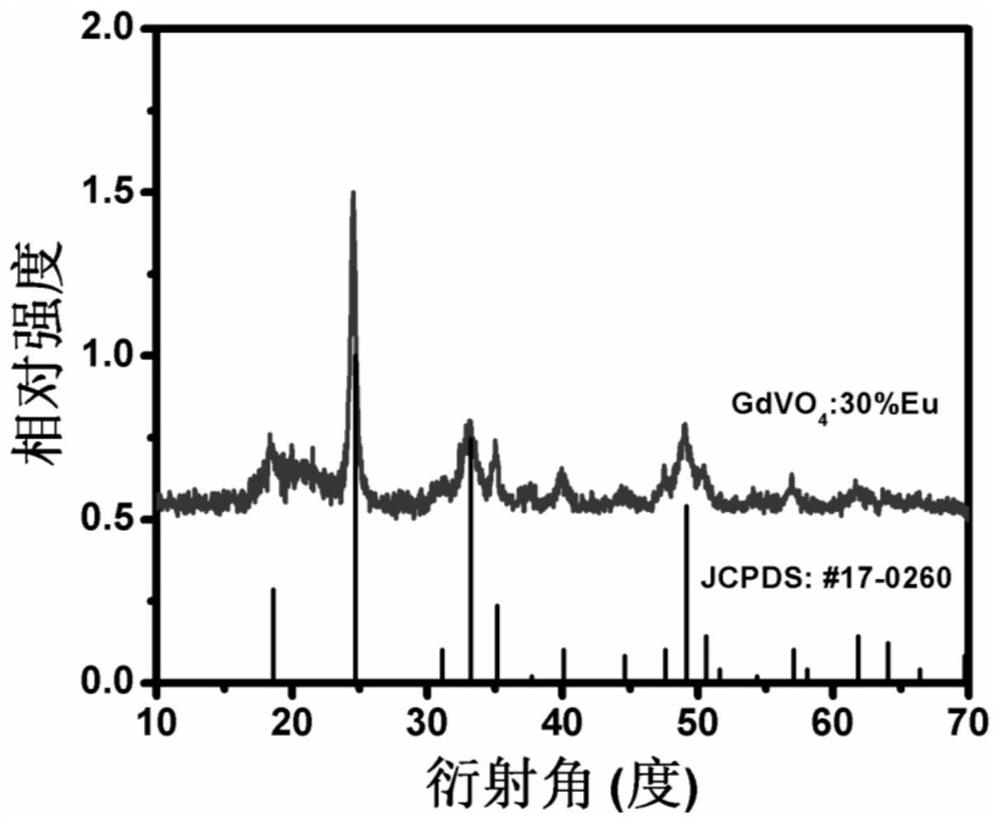

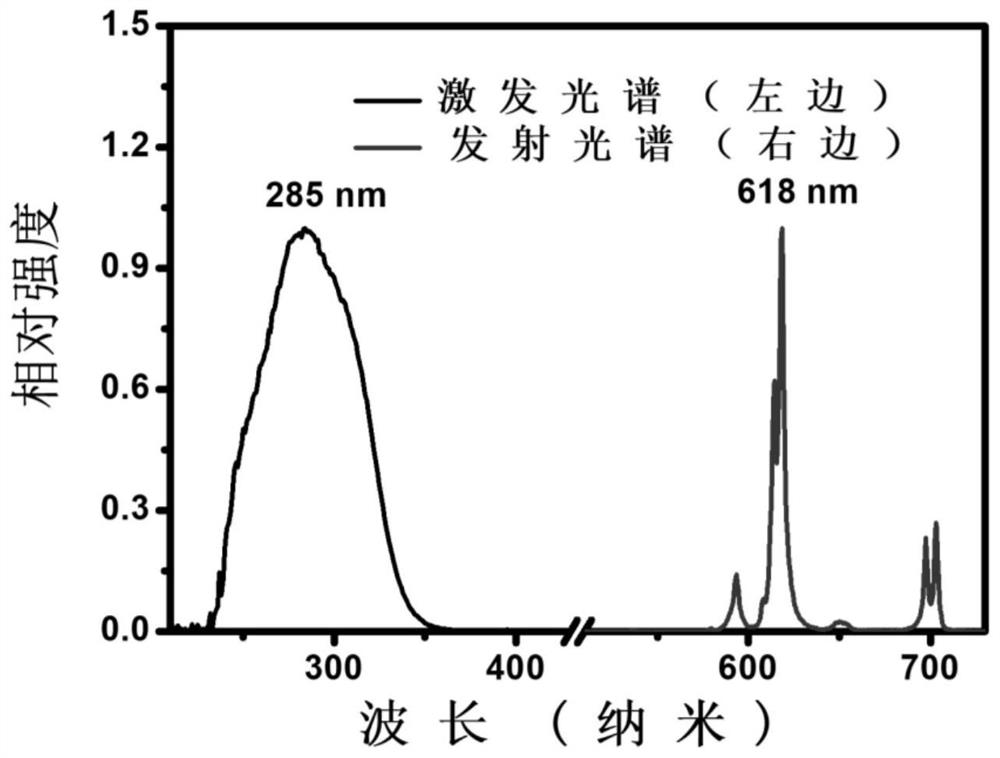

[0047] For the prepared GdVO 4 : 30% Eu nanoparticles were subjected to X-ray powder diffraction test (MiniFlex2, Rigaku), scanning electron microscope test (JSM6700, SEM), fluorescence excitation and emission test (FLS920, Edinburgh Instruments), luminescence decay characteristic test (FLS920, Edinburgh Instruments) .

[0048] figure 1 For the GdVO prepared in Example 1 4 : The X-ray powder diffraction...

Embodiment 2

[0058] Preparation of test strips

[0059] A. Sample binding pad 1 treatment: glass cellulose membrane with buffer solution containing surfactant (recipe: 100 mLPBS, pH 7.4, containing 2% NaCl, 2% BSA, 0.5% casein, 0.1% Tween-0.5% S9 and 5% sucrose) soaked for pre-blocking, dried overnight at 50°C, and sprayed GdVO through the airjet nozzle of the Biodot instrument 4 : 30% Eu-labeled cTnI monoclonal antibody 1 was ultrasonically sprayed at 8 μL / cm onto a glass cellulose membrane with a width of 1 cm, and dried overnight at 50°C to prepare a sample binding pad.

[0060] B. Preparation of nitrocellulose membrane 3: Take 50 mM pH 7.4 phosphate buffer solution to dilute another epitope cTnI monoclonal antibody 2 to 1 mg / mL for T line preparation; use 0.05 M MES Dilute the goat anti-mouse IgG antibody to 1 mg / mL in buffer solution for the preparation of C-line; draw the two diluted antibodies evenly and in parallel on the nitrocellulose membrane with a Biodot film drawer for coati...

Embodiment 3

[0062] Quantitative detection of embodiment 3 samples

[0063] 1. Establishment of standard curve

[0064] Detection method: Prepare standard solutions with cTnI concentrations of 500 pg / mL, 250 pg / mL, 125 pg / mL, 62.5 pg / mL, 31.25 pg / mL, and 15.625 pg / mL, and take calibrator solutions of each concentration 80 μL, respectively added to the test strips prepared in Example 2, after 15 min, use a time-resolved fluorescence quantitative analyzer to quantitatively detect the fluorescence values of the T line and the C line, and test each concentration of the calibrator solution three times, and take the T / C The average value of the value, the specific results are shown in Table 1.

[0065] Table 1

[0066] cTnI (pg / mL) T / C log[cTnI] Log(T / C) 500 4.915 2.698 0.691 250 2.726 2.397 0.435 125 1.113 2.096 0.046 62.5 0.515 1.795 -0.288 31.25 0.226 1.494 -0.645 15.625 0.121 1.193 -0.917

[0067] According to the above test ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com