Strain capable of producing nattokinase at high yield and method for preparing nattokinase product by using strain

A technology of nattokinase and production method, applied in the field of bioengineering, can solve problems such as low activity, and achieve the effects of improving liver function, reducing production cost and protecting activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

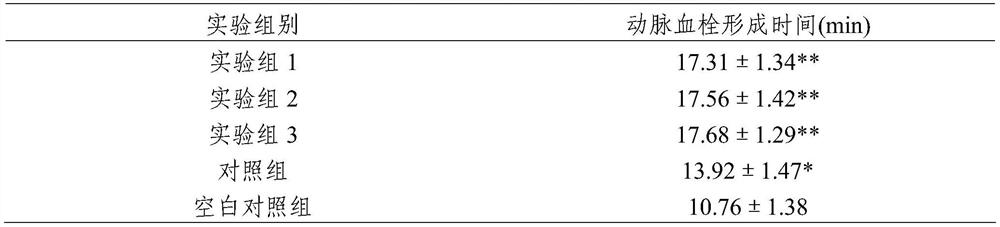

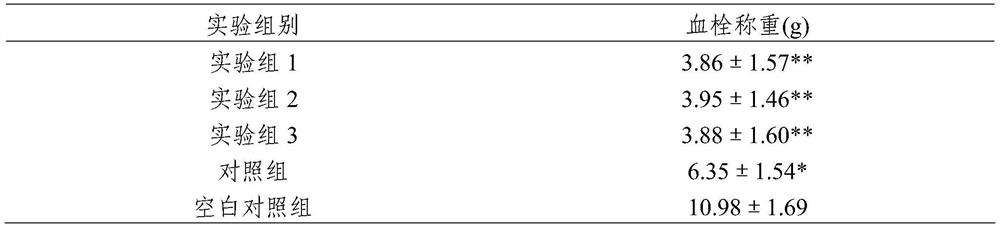

Embodiment 1

[0046] A kind of production method of nattokinase tablet, concrete steps comprise:

[0047] (1) Preparation of nattokinase fermented liquid:

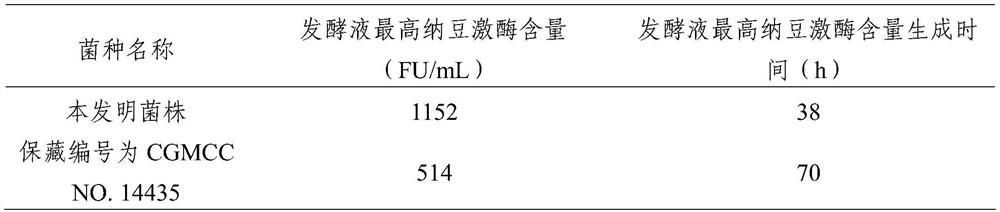

[0048] On a sterile operating table, use an inoculation needle to scrape 1 ring of the activated test tube slant bacteria into 100ml LB medium, shake the temperature at 33°C, rotate at 190r / min, shake and cultivate for 24 hours, and stop the culture when OD600=0.6 , to obtain the seed solution; get the prepared seed solution and inoculate it into the sterilized fermentation medium according to the inoculum size of 1% (v / w) (the fermentation medium consists of glucose 1.5%, xylose 3%, soybean peptone 1% , Ammonium Sulfate 0.3%, Calcium Chloride 0.02%, Disodium Hydrogen Sulfate 0.13%, Sodium Dihydrogen Sulfate 0.05%, Ferrous Chloride 0.003%, Soybean Oil 0.7%, pH7.4), shaker temperature 37 ℃, speed 200r / min, shake culture for 32h, detect that the nattokinase content reaches 1214FU / mL, stop the fermentation, and obtain the nattokinase ferm...

Embodiment 2

[0055] A kind of production method of high nattokinase activity natto, concrete steps comprise:

[0056] (1) Preparation of nattokinase fermented liquid:

[0057] On a sterile operating table, use an inoculation needle to scrape 1 ring of the activated test tube slant bacteria into 100ml LB medium, shake the temperature at 37°C, rotate at 160r / min, shake for 20 hours, and stop the cultivation when OD600=0.5 , to obtain the seed solution; get the prepared seed solution and inoculate it into the sterilized fermentation medium according to the inoculum size of 5% (v / w) (the fermentation medium consists of 2% glucose, 1% xylose, 1.3% soybean peptone , Ammonium Sulfate 0.8%, Calcium Chloride 0.03%, Disodium Hydrogen Sulfate 0.10%, Sodium Dihydrogen Sulfate 0.06%, Ferrous Chloride 0.005%, Soybean Oil 0.5%, pH7.3), shaker temperature 33 ℃, speed 180r / min, shake culture for 38h, detect that the nattokinase content reaches 1096FU / mL, stop the fermentation, and obtain the nattokinase f...

Embodiment 3

[0064] A kind of production method of high nattokinase activity natto, concrete steps comprise:

[0065] (1) Preparation of nattokinase fermented liquid:

[0066] On a sterile operating table, use an inoculation needle to scrape 1 ring of the activated test tube slant bacteria into 100ml LB medium, shake the temperature of 35°C, rotate at 200r / min, shake and cultivate for 18h, and stop the culture when OD600=0.8 , to obtain the seed solution; get the prepared seed solution and inoculate it into the sterilized fermentation medium according to the inoculum size of 2% (v / w) (the fermentation medium consists of: glucose 0.8%, xylose 2%, soybean peptone 2% , ammonium sulfate 0.4%, calcium chloride 0.01%, disodium hydrogen sulfate 0.08%, sodium dihydrogen sulfate 0.08%, ferrous chloride 0.004%, soybean oil 1%, pH7.2), shaking table temperature 36 ℃, rotating speed 160r / min, shake culture for 40h, detect that the nattokinase content reaches 1053FU / mL, stop the fermentation, and obta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com