Method for analyzing mixed acid concentration of silicon etching solution

An analysis method and etching solution technology, which is applied in the direction of chemical analysis by titration method, can solve the problems of increased uncertainty, reduced aperture ratio, and long time consumption, and achieve the effect of improving accuracy and eliminating interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A method for analyzing the mixed acid concentration of silicon etching solution, the steps comprising:

[0037] (1) Use sodium hydroxide as the solute, pure water as the solvent, configure a strong alkali solution with a concentration range of 0.9-1.1mol / L, calibrate the concentration with a standard concentration of HCl solution, and take the nitric acid, hydrofluoric acid and acetic acid to be tested The mixed acid sample, in this mixed acid sample, add ethanol and cyclohexanol respectively to make silicon etching mixed acid solution, the mass volume ratio of mixed acid sample and the solvent added is 1g:100ml, the solvent added is the mixed solution of ethanol and cyclohexanol , the volume ratio of ethanol and cyclohexanol is 1:1, and the total volume of the mixed acid sample and the added solvent is quantitatively 100mL;

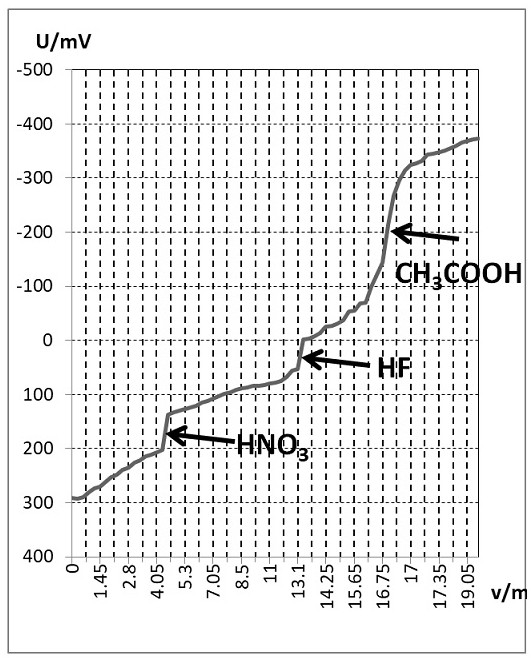

[0038] (2) Drop the calibrated strong alkali solution into the silicon etching mixed acid solution through the automatic potentiometric titrator ...

Embodiment 2

[0054] This embodiment is basically consistent with Example 1, the difference is that the strong base solution is potassium hydroxide solution, the mass volume ratio of the mixed acid sample and the added solvent is 1.7g:100ml, and the volume ratio of ethanol and cyclohexanol in the solvent is 8: 1.

Embodiment 3

[0056]This embodiment is basically consistent with Example 1, the difference is that the strong base solution is potassium hydroxide solution, the mass volume ratio of the mixed acid sample and the added solvent is 0.6g:100ml, and the volume ratio of ethanol and cyclohexanol in the solvent is 5: 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com