Process for preparing calcium magnesium ammonium phosphate from desulfurization wastewater, landfill leachate and phosphorus-containing wastewater

A technology of ammonium calcium magnesium phosphate and landfill leachate, which is applied in dicalcium phosphate fertilizer, degassed water/sewage treatment, polluted groundwater/leachate treatment, etc., can solve the comprehensive treatment of undisclosed wastewater, which is difficult to treat and dispose of Waste salt and other problems to achieve the effect of reducing water consumption and improving economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

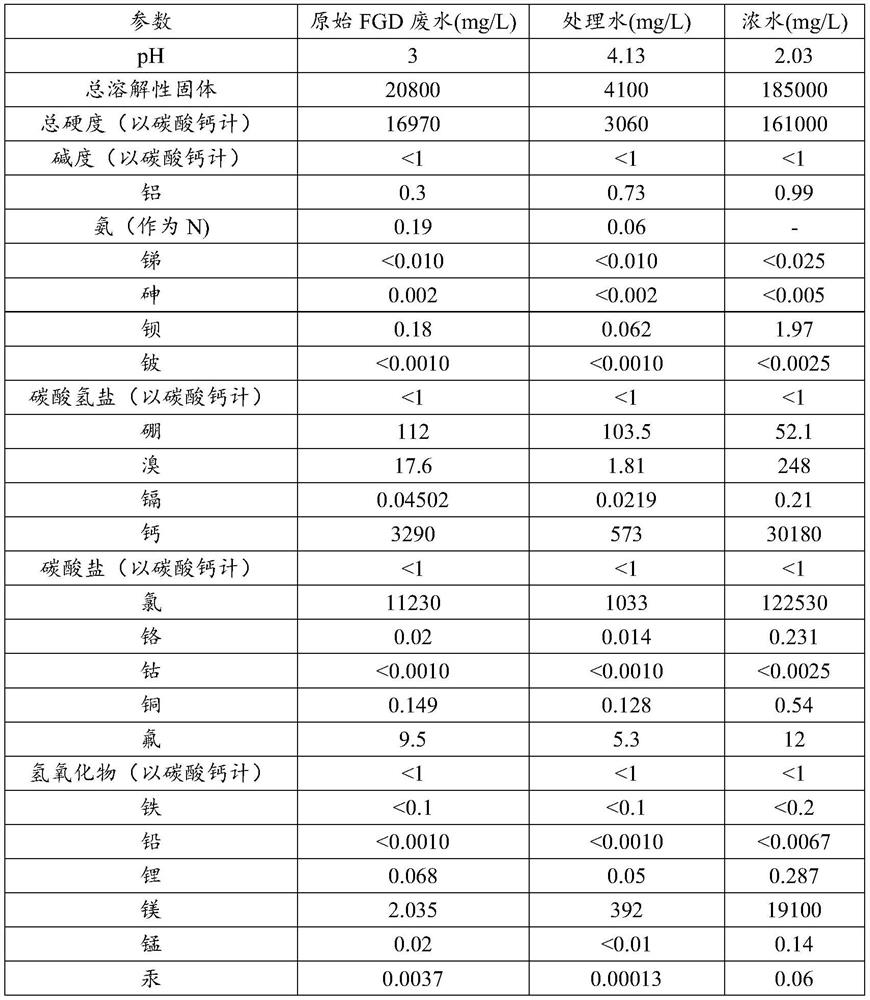

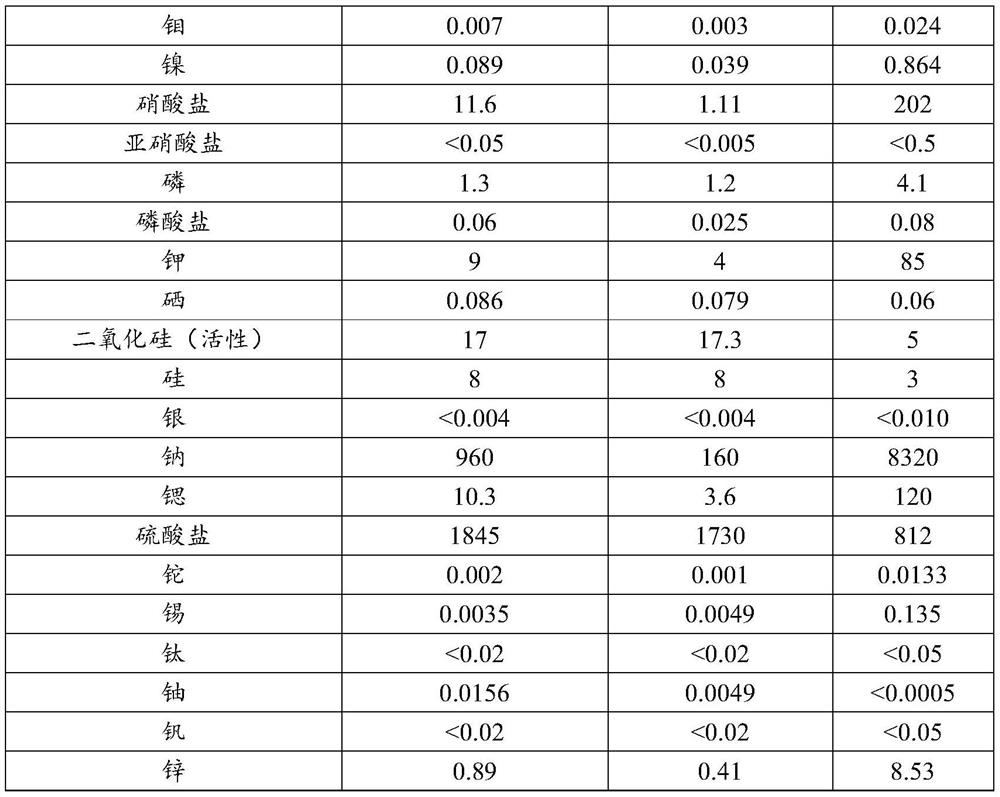

Embodiment 1

[0056] The desulfurization wastewater from a thermal power plant is pumped into the neutralization tank and reaction tank through the wastewater pump. Add Ca(OH) in the neutralization box 2 , adjust the pH of the wastewater to 7-9, so that some heavy metals can be precipitated. Then enter the reaction box, add organic sulfur (TMT15) in the reaction box to further precipitate Hg that cannot be precipitated by hydroxide 2+ 、Cu 2+ , Pb 2+ and other heavy metal ions. Then the wastewater directly enters the ultrafiltration device, and then the divalent calcium ions and magnesium ions are separated by nanofiltration to reduce the load of subsequent electrodialysis treatment, and the produced clean water enters the monovalent ion electrodialysis device for treatment. The main metal ions in the monovalent ion electrodialysis concentrated water side effluent are calcium, magnesium, sodium, chloride ions and a small amount of sulfate ions, TDS>18000mg / L, the concentrated water side ...

Embodiment 2

[0064] Comprehensive treatment of desulfurization wastewater, landfill leachate and phosphogypsum seepage:

[0065] Calcium, magnesium supply unit and ammonia supply unit are the same as embodiment 1. In the phosphorus supply unit, this embodiment uses phosphogypsum seepage liquid as raw material. The phosphogypsum ore seepage fluid is combined with the added polyaluminum sulfate and cationic polyacrylamide in the coagulation reaction tank to precipitate the fine suspended matter in the acidic leachate. The effluent enters an ultrafiltration device and a high-pressure reverse osmosis device that are resistant to acidic materials. Both ultrafiltration and reverse osmosis operate at constant pressure, the ultrafiltration membrane inlet pressure is 2bar, and the membrane outlet pressure is 1.7bar. The reverse osmosis membrane inlet pressure is 10bar, and the membrane outlet pressure is 9bar. The reverse osmosis concentrated water enters the storage tank 3, and the filtrate ent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com