SBD device structure and preparation method thereof

A device structure and epitaxial layer technology, which is applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve the problems of small saturation current, high switching loss, and large turn-on voltage, so as to improve saturation current and breakdown performance, the effect of reducing the turn-on voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

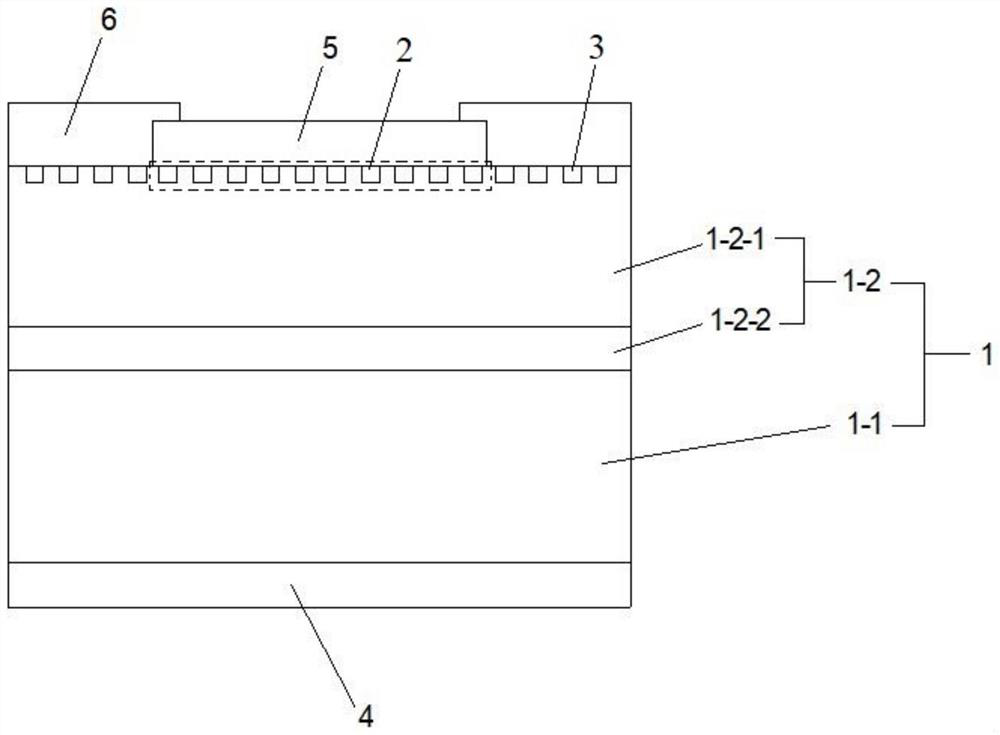

[0070] The preparation method of the floating metal ring 3 is as follows: a floating metal ring accommodation groove is etched on the epitaxial layer 1-2, and the floating metal ring 3 is deposited in the floating metal ring accommodation groove, so as to ensure that the floating metal ring 3 and the epitaxial layer 1-2 flush. For example: the ring width of the floating metal ring 3 is 3-5 μm, and the ring spacing is 3-5 μm.

[0071] In another specific embodiment of the present invention, an insulating layer 6 is grown on the epitaxial layer 1-2 corresponding to the floating metal ring 3, and the material of the insulating layer 6 is silicon nitride, silicon dioxide or aluminum oxide .

[0072] The insulating layer 6 effectively suppresses the electric field breakdown at the edge of the Schottky contact electrode 5 and the surface of the device, increases the reverse breakdown voltage, and effectively improves the performance of the SBD device.

[0073] The above describes ...

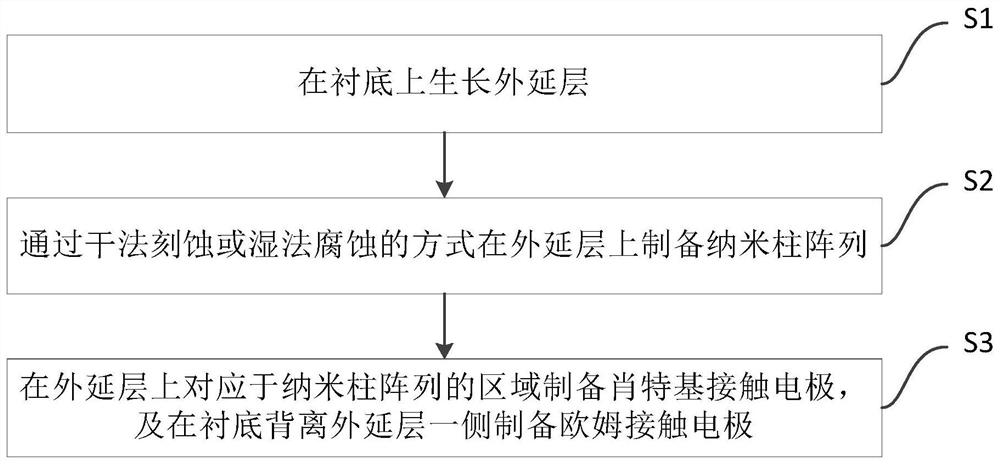

Embodiment 1

[0125] A double-sided polished n-type highly doped self-supporting gallium nitride substrate was selected as the substrate, and organic chemical vapor deposition (MOCVD) was used to sequentially grow the gallium nitride substrate with a thickness of 2 μm and a carrier concentration of 1.5× 10 18 cm -3 the n + type gallium nitride and the thickness is about 23μm, the carrier concentration is about 8×10 15 cm -3 n-type gallium nitride. Hydrogen silanes can be used as Si raw materials for n-type dopants (donors).

[0126] The process parameters of the RTA process in the dry etching process are:

[0127] The annealing temperature is 800°C;

[0128] The annealing time was 60 seconds.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com