Curing agent for curing landfill leachate membrane concentrated liquor and evaporation mother liquor

A technology of landfill leachate and mother liquor evaporation, which is applied in the field of landfill leachate treatment in environmental engineering, can solve the problems of low strength and large consumption, and achieve the effects of improving early strength, reducing production costs, and reducing carbon emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

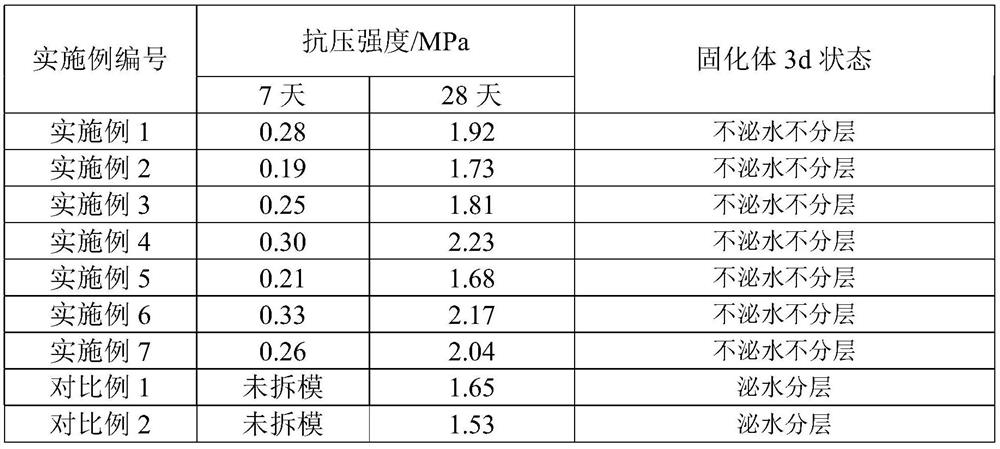

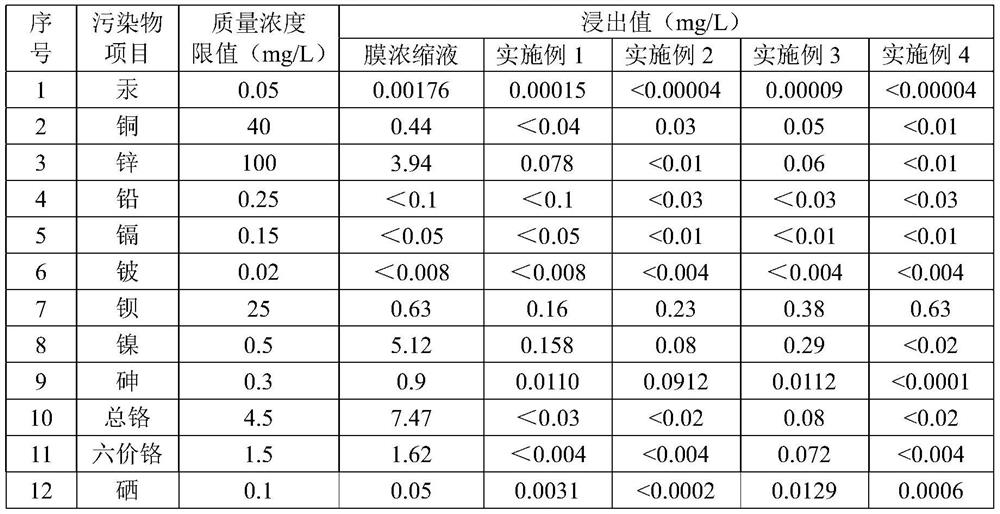

Examples

Embodiment 1

[0017] (1) Take the dry raw materials for the curing agent for the solidified film concentrate according to the following weights: 0.35kg of granulated blast furnace slag powder, 0.15kg of fly ash, 0.15kg of ordinary Portland cement, 0.05kg of calcium oxide, sodium sulfate 0.08kg, calcium formate 0.02kg, chitosan 0.04kg, diatomite 0.08kg, Wenlun glue 0.03kg, desulfurization gypsum 0.03kg, alum stone powder 0.02kg; put the above raw materials into the mixer and mix well Finally, a powdery curing agent is formed, sealed and stored;

[0018] (2) Mix the solidifying agent prepared above with 2.5 kg of the membrane filter concentrate with a water content of 86.6%, stir it evenly with a high-speed mixer, and mold it in a steel test mold, and remove the mold after losing plasticity. The final cured body is cured to the specified age in a standard curing room with a room temperature of 20±2°C and a relative humidity of ≥90%, and then the compressive strength of the cured sample is mea...

Embodiment 2

[0020] (1) Take by weighing the dry raw material of the solidifying agent that is used for curing evaporation mother liquor according to following weight: Granulated blast furnace slag powder 0.3kg, silica fume 0.15kg, ordinary portland cement 0.19kg, calcium hydroxide 0.08kg, sodium carbonate 0.05 kg, guar gum 0.08kg, calcium-based bentonite 0.07kg, natural gypsum 0.03kg, aluminum potassium sulfate dodecahydrate 0.05kg; put the above raw materials into a mixer and mix them to form a powdery curing agent after mixing. save;

[0021] (2) Mix the curing agent prepared above with 2.5 kg of the evaporated mother liquor with a water content of 75.78%, stir it evenly with a high-speed mixer, and mold it in a steel test mold. After losing the plasticity, the mold is removed, and the cured body after the mold is removed Measure the compressive strength of the cured sample after curing to the specified age in a standard curing room with a room temperature of 20±2°C and a relative humid...

Embodiment 3

[0023] (1) Take by weighing the dry raw material of the solidifying agent that is used for solidified film concentrated solution according to following weight: Granulated blast furnace slag powder 0.4kg, calcined coal gangue powder 0.1kg, ordinary portland cement 0.1kg, sodium sulfate 0.03kg, carbonic acid 0.09kg of sodium, 0.03kg of calcium formate, 0.08kg of sodium bentonite, 0.04kg of aluminum sulfate, 0.03kg of polymer water-absorbing resin, and 0.1kg of quick-hardening sulfur-aluminum cement; Form a powdery curing agent and keep it sealed;

[0024] (2) Mix the above-mentioned solidifying agent prepared with 2.5 kg of the membrane filter concentrate with a water content of 85.96%, stir it evenly with a high-speed mixer, and mold it in a steel trial mold. After losing the plasticity, remove the mold. The cured body is cured in a standard curing room with a room temperature of 20±2°C and a relative humidity of ≥90%, and then the compressive strength of the cured sample is me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com