Preparation method of recombinant manganese peroxidase and application of recombinant manganese peroxidase in degradation of Chinese herbal medicine lignin

A technology of manganese peroxidase and encoding manganese peroxide, which is applied in the preparation of recombinant manganese peroxidase and the application field of Chinese herbal medicine lignin degradation, can solve the problems of lack of reports, long fermentation time, increased production costs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

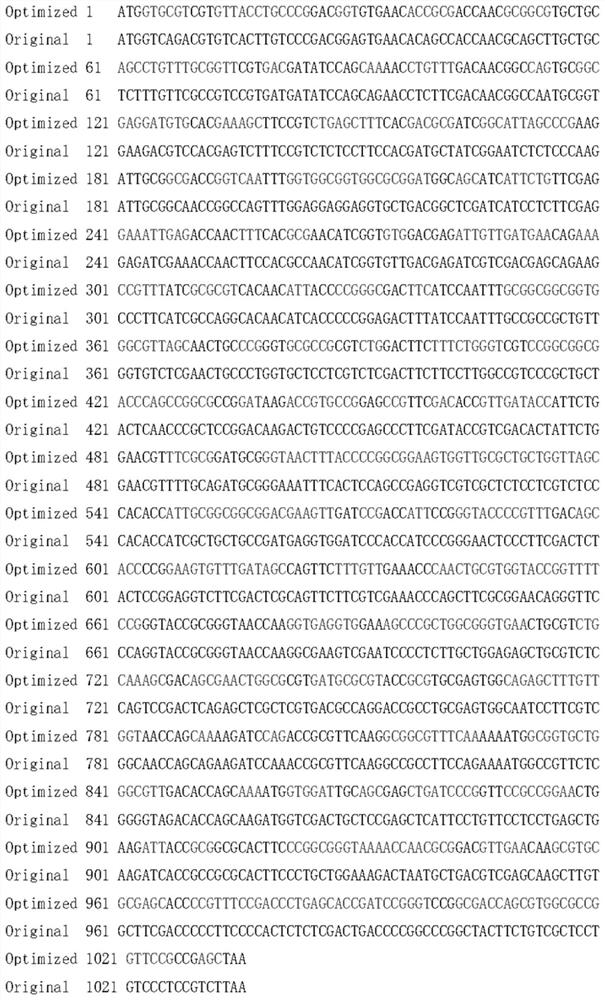

[0047] The manganese peroxidase gene sequence of Irpex lacteus in NCBI (GenBank: MH120207.1), the amino acid sequence is shown in SEQ ID NO.2; according to the codon bias in Schizosaccharomyces pombe, the gene sequence needs to be optimized , the codon optimization method is: through the Graphical Codon Usage Analyzer (http: / / gcua.schoedl.de / ) online system, analyze the usage frequency of codons in the manganese peroxidase (MnP) gene, so as to select suitable Codons for the transcription-translation system of Saccharomyces cerevisiae. figure 1 It is the alignment diagram of the original sequence of the manganese peroxidase gene and the codon-optimized sequence, and the nucleotide sequence of the codon-optimized recombinant MnP gene is shown in SEQ ID NO.1.

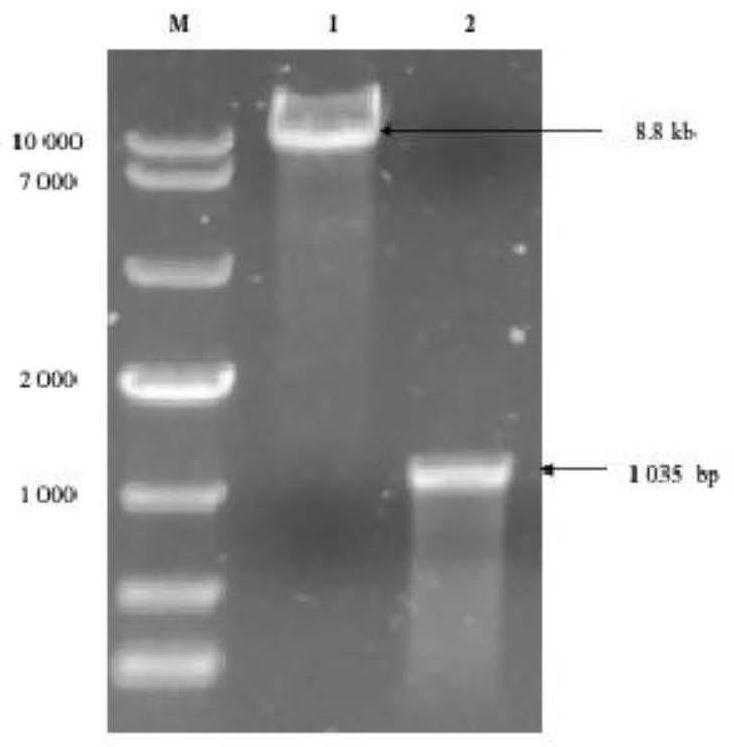

[0048] Using pREP, a commonly used carrier for yeast, as a template, design primers to amplify the target gene sequence. The sequence of the forward primer is shown in SEQ ID NO.3, and the sequence of the reverse primer is...

Embodiment 2

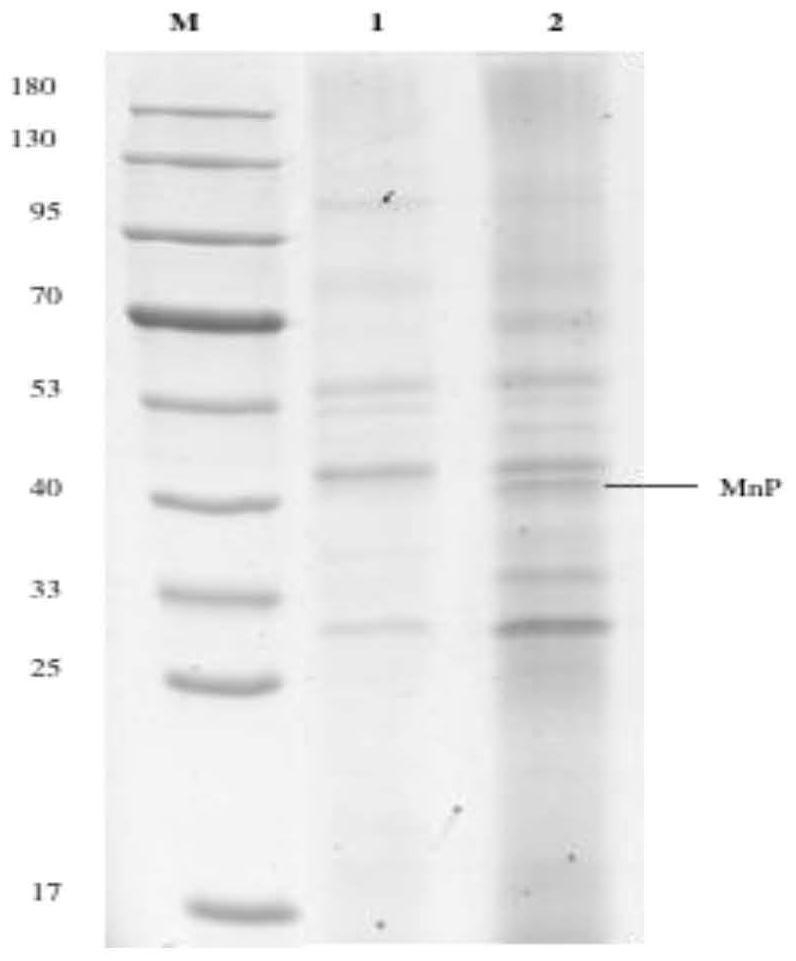

[0050] Expression verification of recombinant manganese peroxidase;

[0051] Dip the S.pombe-pREP-mnp and S.pombe-pREP cultures stored at -80°C and the control group S.pombe-pREP, streak on the plate, and grow statically in a constant temperature incubator at 30°C for 3 days; The colony was transferred into a 50mL screw-top conical centrifuge tube, and cultured with 5mL of YES culture solution in the tube, 200rpm, and 30°C constant temperature shaking. After the yeast culture reaches the plateau stage, collect 50 mL of yeast cells, centrifuge at 8 000 rpm, and transfer 12 mL of the supernatant culture solution to the protein concentrator for four times to concentrate the extracellular secreted protein; after concentrating to the minimum amount, add 12 mL of 20 mM Tris-HCl (pH 7.0) was used to wash extracellular secreted proteins to remove sugars, ions and other impurities in the supernatant culture solution; after SDS-PAGE electrophoresis analysis, there were specific bands in...

Embodiment 3

[0053] Weighing Chinese herbal medicine Eucommia ulmoides and Radix Astragali, this example discusses the degradation effect of recombinant MnP enzyme on lignin under different material-to-liquid ratios, enzymatic hydrolysis time, and enzyme dosage; The liquid part obtained by solid-liquid separation is the crude enzyme liquid; the crude enzyme liquid is mixed with Eucommia ulmoides and Astragalus membranaceus in a certain proportion, placed in a constant temperature and humidity incubator at 40°C for enzymolysis reaction for 24 hours, dried at 105°C to constant weight, and used The Van Soest method was used to measure the change of lignin content by FIWE3 / 6 fiber analyzer.

[0054] (1) The effect of solid-liquid ratio on lignin degradation;

[0055] According to the solid-liquid ratio of 10:1, 5:1, 2:1, 1:1, 0.5:1, weigh different quality Eucommia and Radix Astragali and mix them with crude enzyme solution, and place them in a constant temperature and humidity incubator at 40...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com