Self-repairing organic fluorine-silicon modified polyurethane waterproof coating and preparation method thereof

A technology of silicon-modified polyurethane and waterproof coatings, applied in the direction of polyurea/polyurethane coatings, antifouling/underwater coatings, coatings, etc., to achieve the effects of improving stability, improving mechanical properties, and improving hydrophobicity and oleophobicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

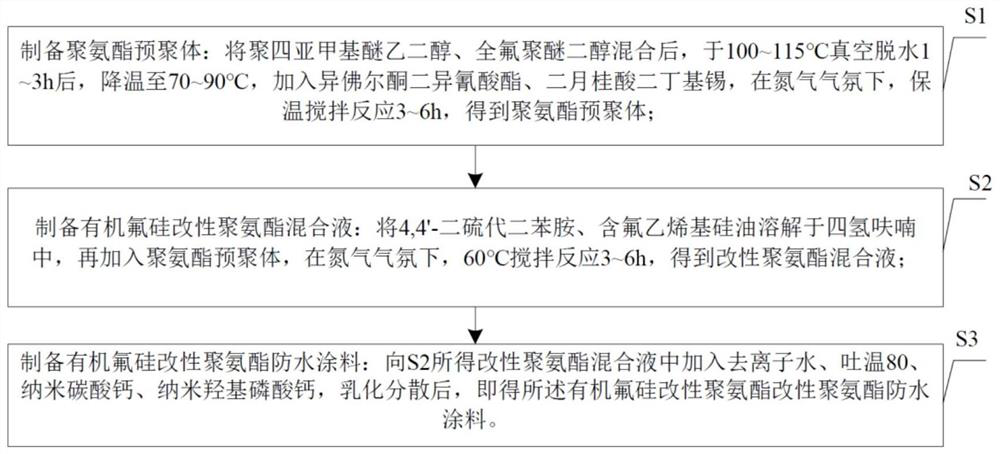

[0022] The preparation method of self-repairing organic fluorine silicon modified polyurethane waterproof coating comprises the following steps:

[0023] S1: Preparation of fluorine-containing hydroxy silicone oil: After mixing trifluoropropylmethylcyclotrisiloxane, tridecafluorooctyltriethoxysilane, and hydroxy silicone oil evenly, add ethylenediamine catalyst dropwise, and nitrogen gas, 100 ℃ and stirred for 3 hours, then ethylenediamine was rotated and evaporated at 120℃ to obtain fluorine-containing hydroxy silicone oil; the trifluoropropylmethylcyclotrisiloxane, tridecafluorooctyltriethoxysilane, hydroxy silicone oil, ethyl The mass ratio of the diamine catalyst is 1:0.4:1.8:0.01;

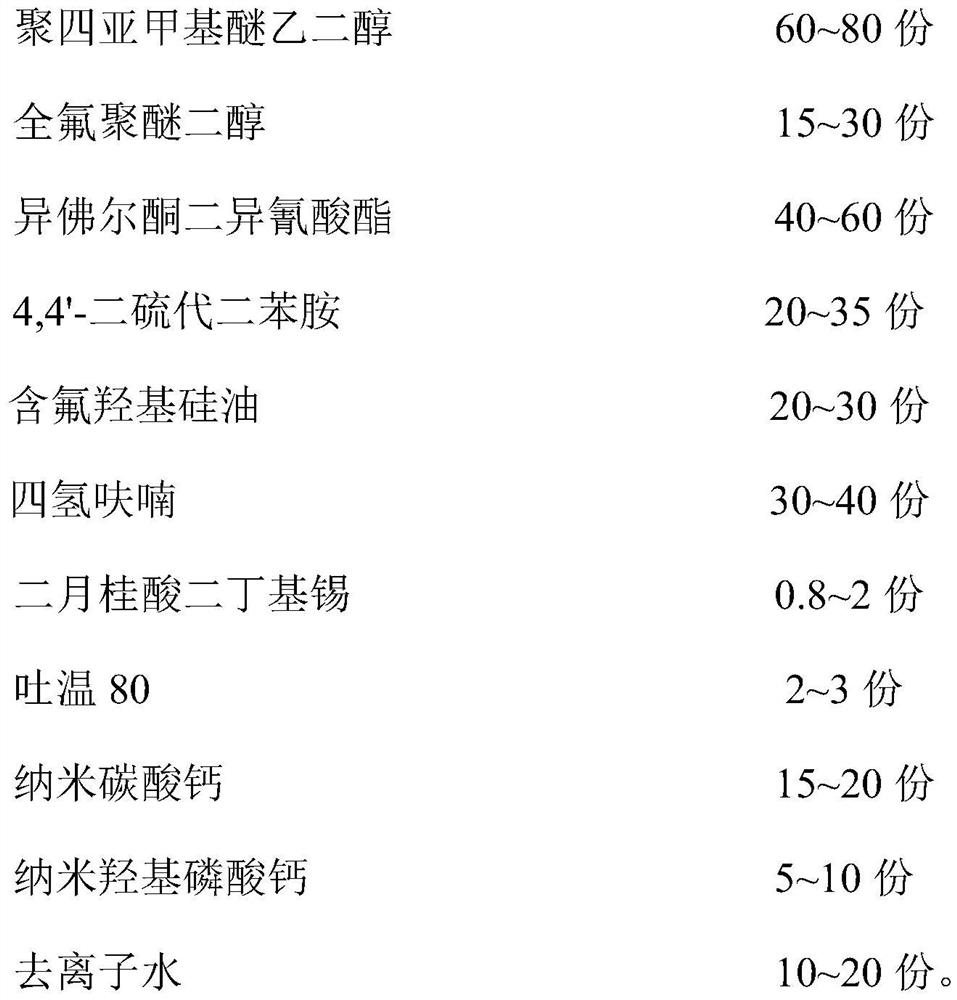

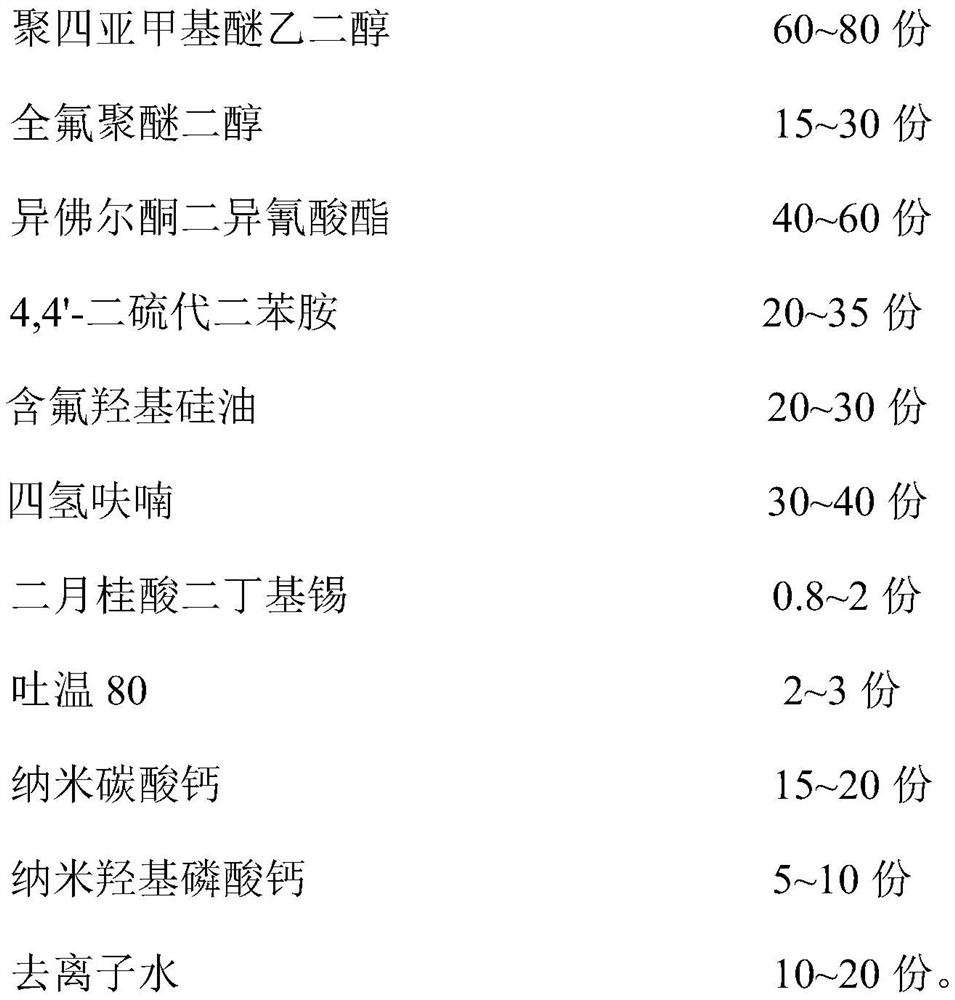

[0024] S2: Material preparation: Weigh 60 parts of polytetramethylene ether glycol, 15 parts of perfluoropolyether glycol, 40 parts of isophorone diisocyanate, 20 parts of 4,4'-dithiodiphenylamine 20 parts, 20 parts of fluorine-containing hydroxyl silicone oil, 30 parts of tetrahydrofuran, 0....

Embodiment 2

[0029] The preparation method of self-repairing organic fluorine silicon modified polyurethane waterproof coating comprises the following steps:

[0030] S1: Preparation of fluorine-containing hydroxy silicone oil: After mixing trifluoropropylmethylcyclotrisiloxane, tridecafluorooctyltriethoxysilane, and hydroxy silicone oil evenly, add ethylenediamine catalyst dropwise, and nitrogen gas, 110 ℃ and stirred for 5 hours, then ethylenediamine was rotated and evaporated at 120℃ to obtain fluorine-containing hydroxy silicone oil; the trifluoropropylmethylcyclotrisiloxane, tridecafluorooctyltriethoxysilane, hydroxy silicone oil, ethyl The mass ratio of the diamine catalyst is 1:0.6:2.4:0.03;

[0031] S2: Material preparation: Weigh 70 parts of polytetramethylene ether glycol, 25 parts of perfluoropolyether glycol, 50 parts of isophorone diisocyanate, 27 parts of 4,4'-dithiodiphenylamine 25 parts, 25 parts of fluorine-containing hydroxyl silicone oil, 35 parts of tetrahydrofuran, 1....

Embodiment 3

[0036] The preparation method of self-repairing organic fluorine silicon modified polyurethane waterproof coating comprises the following steps:

[0037] S1: Preparation of fluorine-containing hydroxy silicone oil: After mixing trifluoropropylmethylcyclotrisiloxane, tridecafluorooctyltriethoxysilane, and hydroxy silicone oil evenly, add ethylenediamine catalyst dropwise, and nitrogen gas, 115 ℃ stirring reaction for 8 hours, ethylenediamine was rotated and evaporated at 120℃ to obtain fluorine-containing hydroxy silicone oil; the trifluoropropylmethylcyclotrisiloxane, tridecafluorooctyltriethoxysilane, hydroxy silicone oil, ethyl The mass ratio of the diamine catalyst is 1:0.8:3:0.05;

[0038] S2: Material preparation: Weigh 80 parts of polytetramethylene ether glycol, 30 parts of perfluoropolyether glycol, 60 parts of isophorone diisocyanate, 35 parts of 4,4'-dithiodiphenylamine 30 parts, 30 parts of fluorine-containing hydroxyl silicone oil, 40 parts of tetrahydrofuran, 2 p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com