Surface-modified wollastonite as well as preparation method and application thereof

A technology of surface modification and wollastonite, which is applied in coatings, adhesive additives, non-polymer adhesive additives, etc., can solve problems such as uneven dispersion, increased viscosity of the mixed system, and poor dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

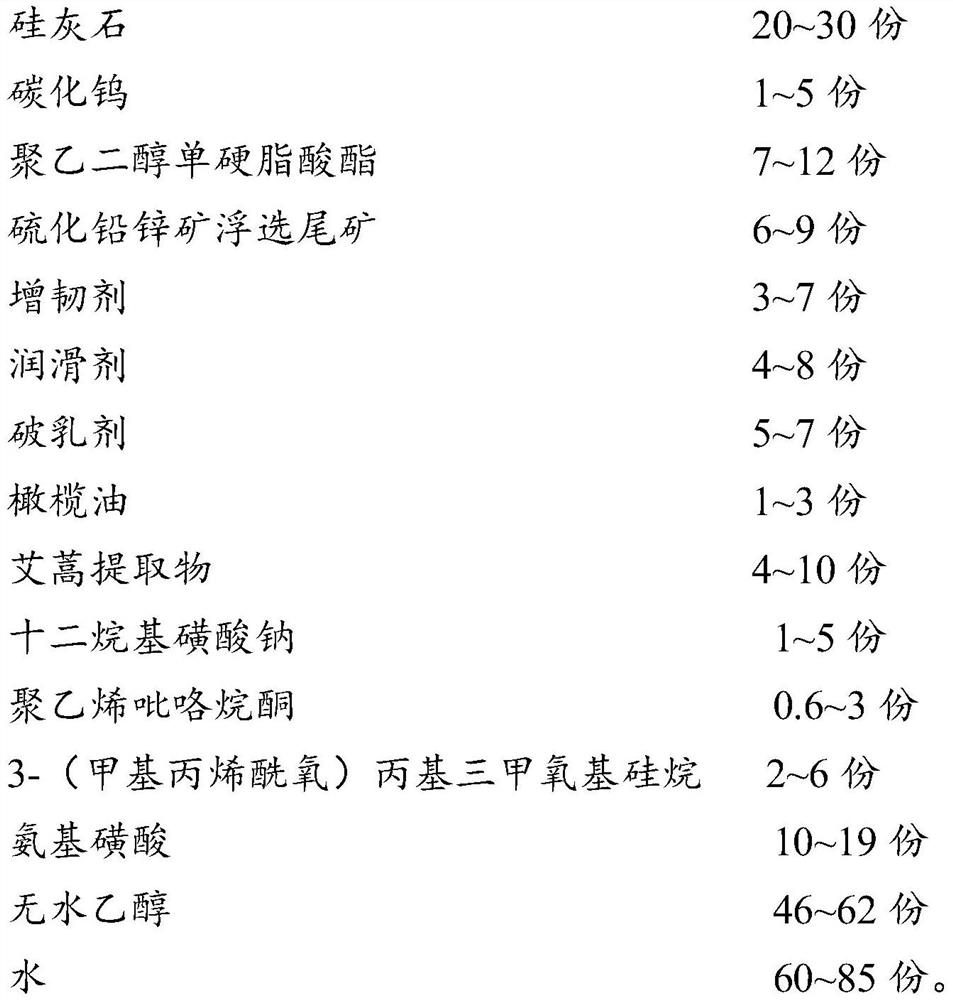

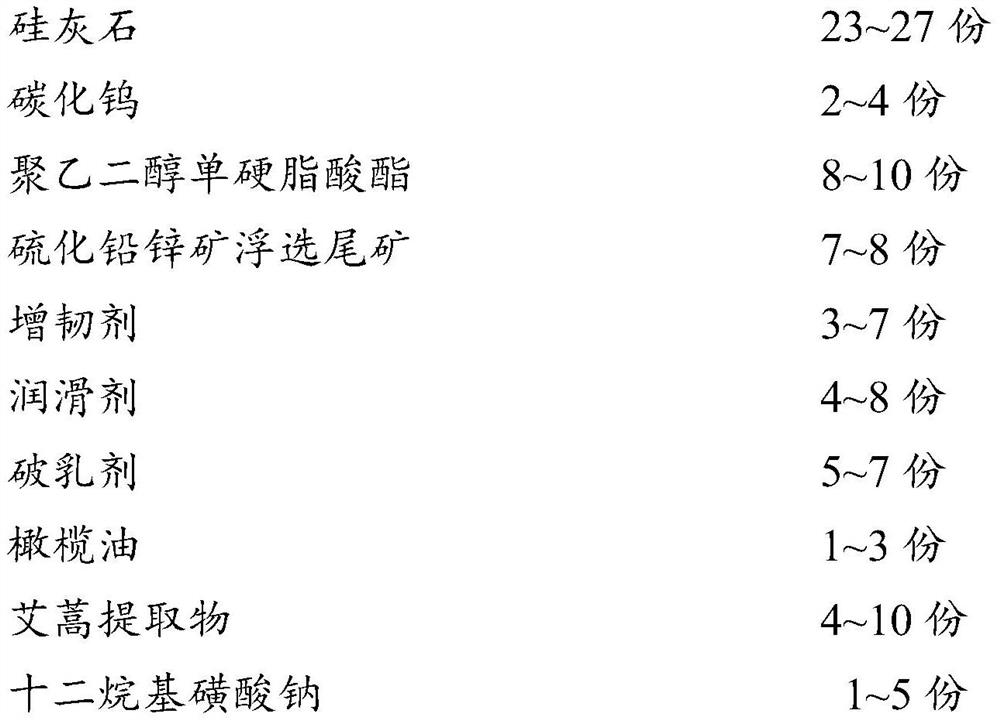

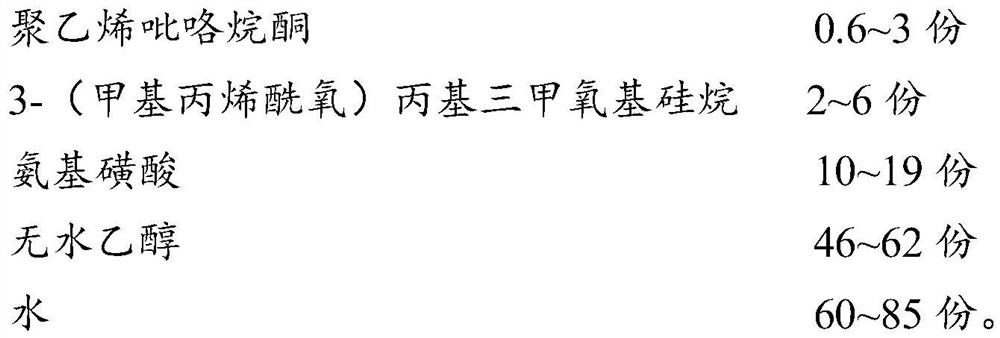

[0054] The present invention also provides a method for preparing the surface-modified wollastonite described in the above technical solution, comprising the following steps:

[0055] After first mixing wollastonite, tungsten carbide, polyethylene glycol monostearate, flotation tailings of lead-zinc ore, lubricant and toughening agent, the first mixture is obtained;

[0056] 3-(methacryloyloxy)propyltrimethoxysilane, sodium dodecylsulfonate and part of water are mixed for the second time to obtain the first solution;

[0057] Mixing polyvinylpyrrolidone, olive oil, mugwort extract and ethanol for a third time to obtain a second solution;

[0058] Carry out the 4th mixing with sulfamic acid and remaining water, obtain the 3rd solution;

[0059] The first mixture, the first solution, the second solution, the third solution and the demulsifier are mixed for the fifth time, and then dried to obtain the surface-modified wollastonite.

[0060] In the present invention, the first m...

Embodiment 1

[0070] 20g of wollastonite, 1g of tungsten carbide, 7g of polyethylene glycol monostearate and 6g of lead-zinc ore flotation tailings were mixed and ground for 1 hour, and 4g of lubricants (polyethylene wax, solid paraffin and liquid paraffin were added) The mass ratio is 1:3:4) and the ethylene-1-octene copolymer of 3g, continue grinding 1h, obtain the first mixture;

[0071] Under stirring conditions, 2g of 3-(methacryloyloxy)propyltrimethoxysilane, 1g of sodium dodecylsulfonate and 60g of water were mixed to obtain a first solution;

[0072] Under stirring conditions, mix 0.6g of polyvinylpyrrolidone and 46g of absolute ethanol until the polyvinylpyrrolidone is completely dissolved, then add 1g of olive oil and 4g of mugwort extract in sequence, and continue stirring for 5min to obtain the second solution ;

[0073] Under stirring condition, 10g sulfamic acid and 15g water are mixed, obtain the 3rd solution;

[0074] After the first mixture and the first solution were mix...

Embodiment 2

[0076] 30g wollastonite, 5g tungsten carbide, 8g polyethylene glycol monostearate and 9g lead-zinc ore flotation tailings were mixed and ground for 1 hour, and 8g of lubricants (polyethylene wax, solid paraffin and liquid paraffin were added) The mass ratio is 1:3:4) and the ethylene-1-octene copolymer of 7g, continue grinding 1h, obtain the first mixture;

[0077] Under stirring conditions, 6g of 3-(methacryloyloxy)propyltrimethoxysilane, 5g of sodium dodecylsulfonate and 60g of water were mixed to obtain a first solution;

[0078] Under the condition of stirring, 3g of polyvinylpyrrolidone and 46g of absolute ethanol were mixed until the polyvinylpyrrolidone was completely dissolved, then 3g of olive oil and 10g of mugwort extract were added in sequence, and the stirring was continued for 5 minutes to obtain the second solution;

[0079] Under stirring condition, 19g sulfamic acid and 25g water are mixed, obtain the 3rd solution;

[0080] After the first mixture and the fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com