Visible-light-induced photocatalyst and preparation method and application thereof

A photocatalyst, zeolite material technology, applied in molecular sieve catalysts, chemical instruments and methods, botanical equipment and methods, etc., can solve problems such as hindering the wide application of photocatalysts, difficulty in large-scale production and application, and complex photocatalyst synthesis, etc. Achieve excellent photocatalytic performance, improve photocatalytic activity, and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

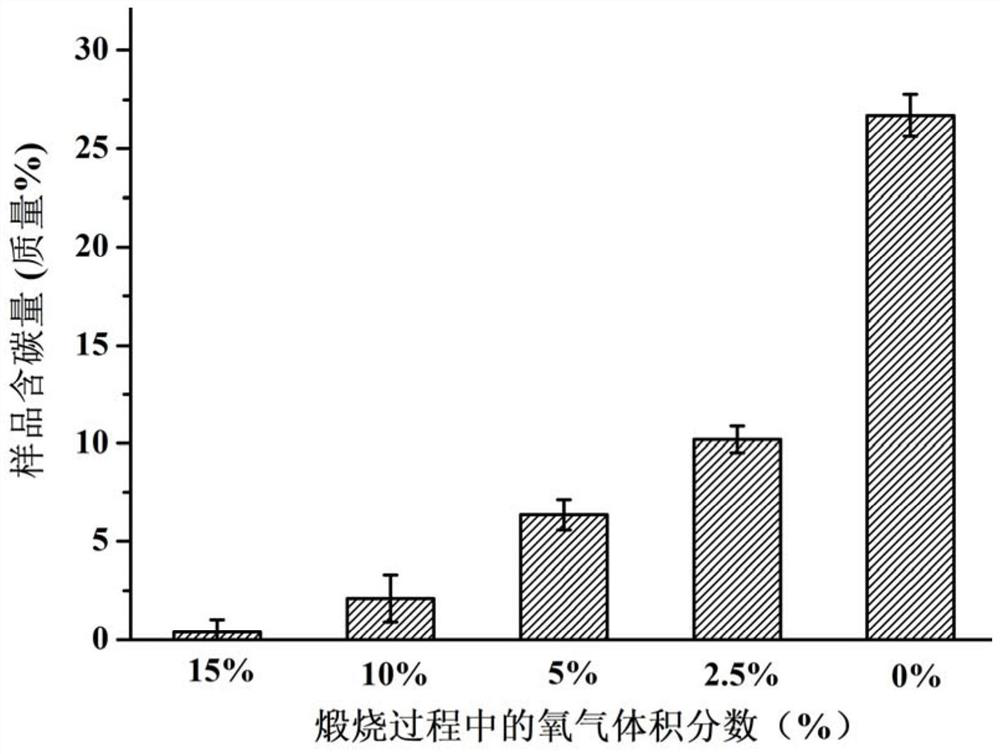

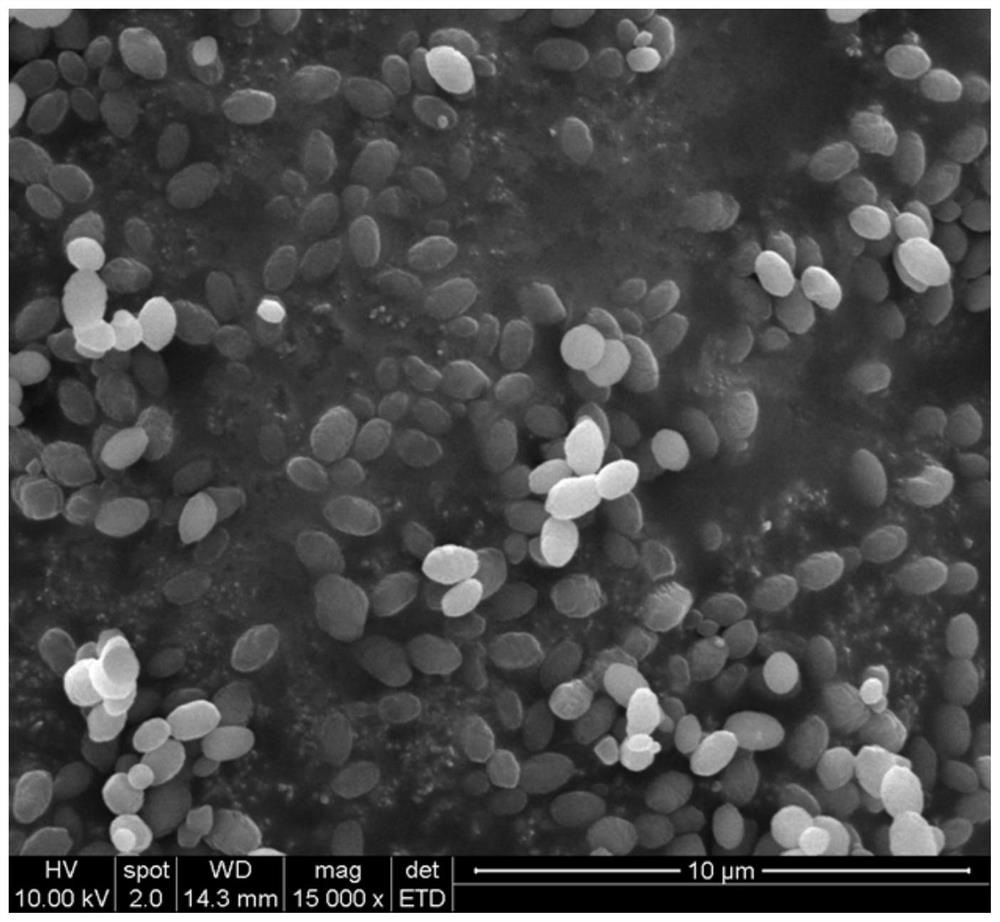

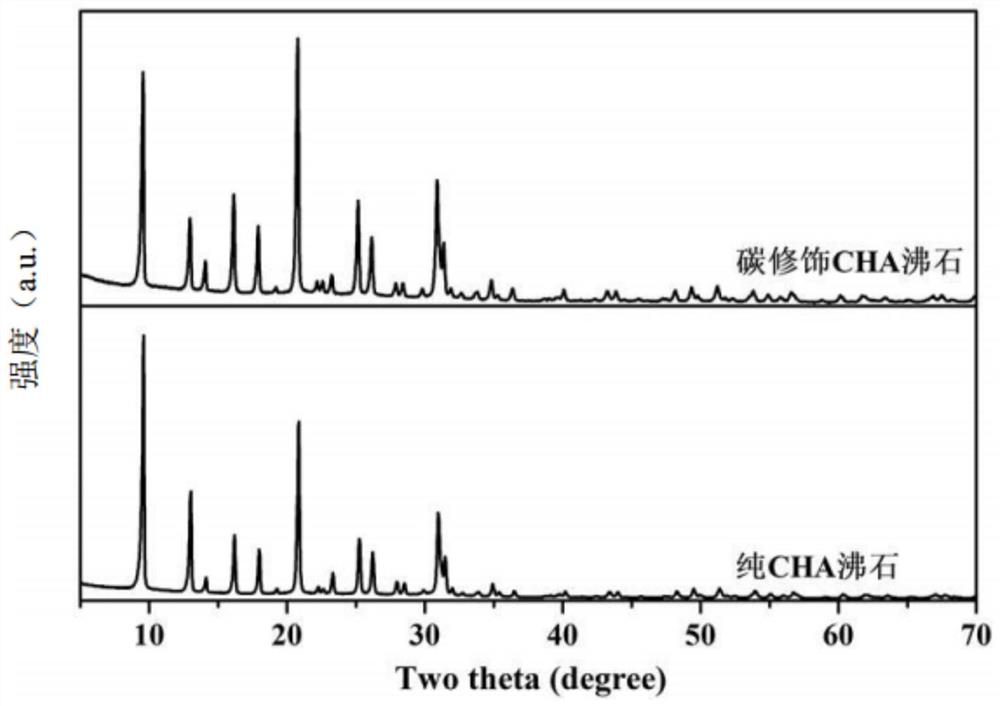

[0076] 39.6 g of trimethyladamantane ammonium hydroxide aqueous solution (25% by mass fraction) and 19.5 g of tetraethoxysilane were dissolved in 4.05 g of water and stirred evenly. Then add 1.05g aluminum triethoxide to this solution and stir well. Subsequently, the above solution was transferred to a high-pressure reactor, and heated in an oven for 6 days at a heating temperature of 140° C. to obtain a white product. The resulting white product was centrifuged, washed, dried and ground. Then the product is placed in a tube furnace for calcination for 8h, the calcination atmosphere is an oxygen-helium gas atmosphere, wherein the volume fraction of oxygen is controlled at 0%, 2.5%, 5%, 10%, 15%, and the calcination temperature is 550 ℃. When the oxygen volume fraction is 2.5%-10%, it can ensure that all (or most) of the organic template is converted into a single form of carbon, and the carbon content is about 2%-10%. This carbon will enter the zeolite framework in the form...

Embodiment 2

[0086] Dissolve 89.6g of tetraethylammonium hydroxide, 0.53g of sodium chloride and 1.44g of potassium chloride in 59.4g of water, and stir evenly at room temperature to form solution A. Mix 29.54g of silicon dioxide (purity 99%) with solution A, stir well, and use it as solution B. Solution C was formed by dissolving 0.33 g of sodium hydroxide and 1.79 g of sodium chlorate in 20 g of water. Solution B and solution C were mixed and stirred evenly, then transferred to a high-pressure reactor for heating at a heating temperature of 135° C. for 20 hours. The resulting product was collected, dried and ground, and then the product was calcined in a tube furnace. The calcining atmosphere was an oxygen-helium gas atmosphere, wherein the volume fraction of oxygen was 0.1%, 1.5% and 10%, respectively, and the calcining temperature was 550°C, the calcination time is 8h. Since the content of the organic template in the BEA zeolite is lower than that of the CHA zeolite, the volume fract...

Embodiment 3

[0093] 0.05g of the carbon-modified CHA type (carbon content 7%) prepared by calcining under 5% oxygen in Example 1 above or the carbon-modified BEA type prepared by calcining under 1.5% oxygen in Example 2 The zeolite photocatalyst (7% carbon content) was dispersed in 50 mL of rhodamine B dye solution, and the concentration of rhodamine B was 50 ppm. At room temperature, irradiate with a 300-watt xenon lamp equipped with a UV intercept filter as a visible light source (≥420nm), take 2 mL of the suspension every 20 minutes for centrifugation, and then take 1 mL of the supernatant, and use UV-visible light spectrophotometry The concentration of rhodamine B was detected by the instrument.

[0094] like Figure 17 It was shown that under visible light irradiation, the carbon-modified CHA-type zeolite photocatalyst can completely degrade rhodamine B within 60 min, exhibiting an excellent ability of visible light-driven photocatalytic degradation of pollutants. In contrast, pure ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com