Preparation method of graphene and zinc selenide and cadmium selenide core-shell microsphere composite nano material

A technology of composite nanomaterials and zinc selenide, which is applied in the field of preparation of graphene and zinc selenide@cadmium selenide core-shell microsphere composite nanomaterials, can solve the problems of high toxicity and the need to improve the third-order nonlinear optical properties , to achieve the effect of strong nonlinear optical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

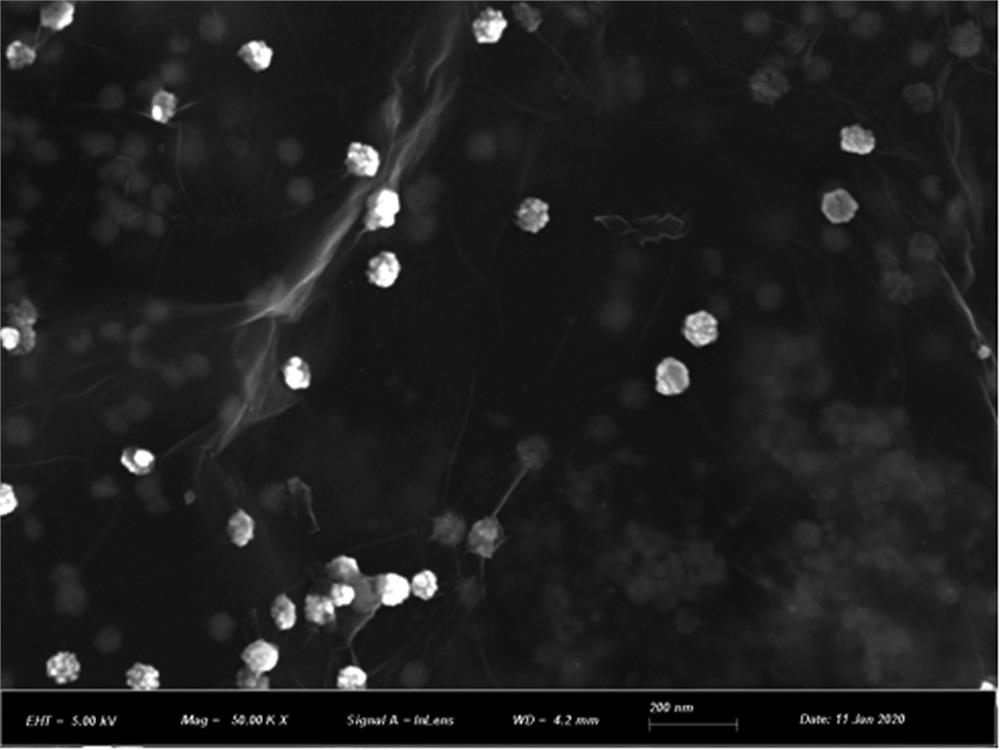

Embodiment 1

[0030] A: First add 0.039g (0.5mmol) of selenium powder and 0.378g (3mmol) of sodium sulfite into a three-necked flask, then add 34ml of deionized water, and add magnets; put the three-necked flask into a constant temperature collector type magnetic stirrer and The three-necked flask was protected with nitrogen, and reacted at 80° C. for 5 h to obtain a colorless and transparent sodium selenosulfate solution.

[0031] B: Put 0.053 g (0.288 mmol) of zinc acetate, 0.059 g (0.255 mmol) of cadmium acetate and 0.378 g of graphene oxide into a beaker, and add 17 ml of deionized water to the beaker, and stir and sonicate for 10 min on a magnetic stirrer , zinc acetate, cadmium acetate and graphene oxide were completely dissolved in deionized water, then the sodium selenosulfate solution prepared in the above steps was added, and placed on a magnetic stirrer to stir continuously, 10ml of hydrazine hydrate was added, stirred for 5min, and mixed liquid;

[0032] C: Transfer the mixed s...

Embodiment 2

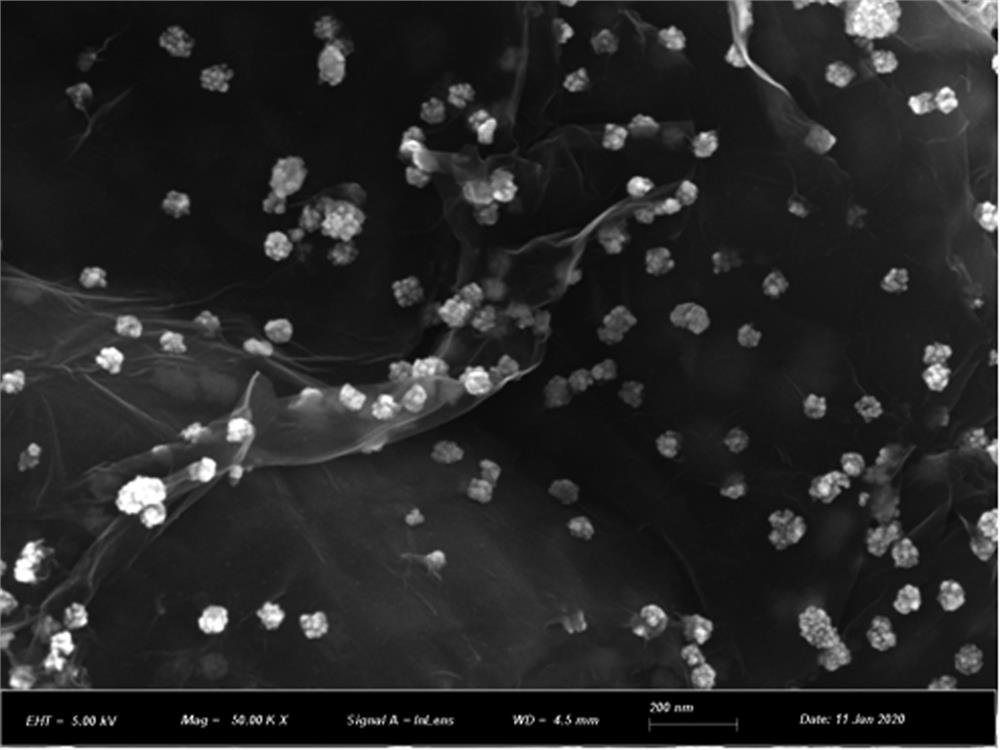

[0036] The present embodiment is basically the same as Example 1, except that step B is: 0.053 g zinc acetate, 0.059 g cadmium acetate and 0.16 g graphene oxide are put into a beaker, and 17 ml of deionized water is added to the beaker, and Stir ultrasonically on a magnetic stirrer for 10 min, so that zinc acetate, cadmium acetate and graphene oxide are completely dissolved in deionized water, then add the sodium selenosulfate solution prepared in step 1, and put it on a magnetic stirrer to continuously stir, Add 10ml of hydrazine hydrate and stir for 5min to obtain a mixed solution.

[0037] The composite nanomaterial of graphene and zinc selenide@cadmium selenide core-shell microspheres prepared in this example is denoted as G / ZnSe@CdSe-2.

[0038] SEM images of G / ZnSe@CdSe-2 composite nanomaterials figure 2As shown, we can clearly see from the scanning electron microscope that the ZnSe / CdSe core-shell nanospheres have been successfully composited with graphene, and the co...

Embodiment 3

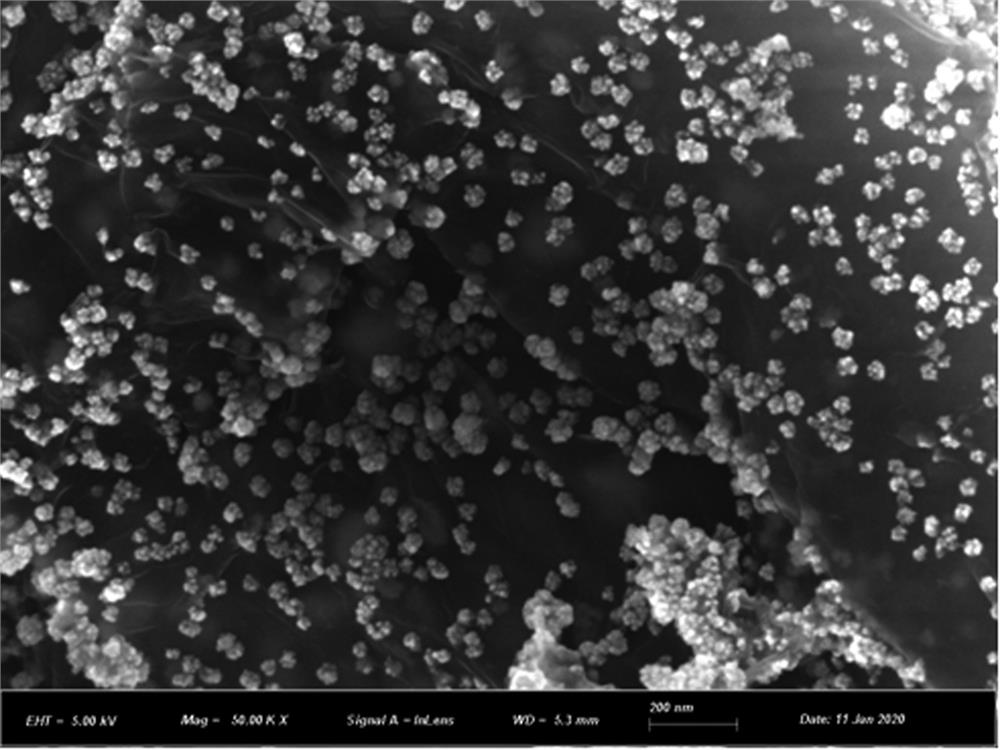

[0040] The present embodiment is basically the same as Example 1, except that step B is: 0.053 g zinc acetate, 0.059 g cadmium acetate and 0.112 g graphene oxide are put into a beaker, and 17 ml of deionized water is added to the beaker, and Stir ultrasonically on a magnetic stirrer for 10 min, so that zinc acetate, cadmium acetate and graphene oxide are completely dissolved in deionized water, then add the sodium selenosulfate solution prepared in step 1, and put it on a magnetic stirrer to continuously stir, Add 10ml of hydrazine hydrate and stir for 5min to obtain a mixed solution.

[0041] The composite nanomaterial of graphene and zinc selenide@cadmium selenide core-shell microspheres prepared in this example is denoted as G / ZnSe@CdSe-3.

[0042] SEM images of G / ZnSe@CdSe-3 composite nanomaterials image 3 As shown, we can clearly see from the SEM images that the ZnSe / CdSe core-shell nanospheres have been successfully composited with graphene.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com