Metallization method and solar cell

A metallization and stacking metal technology, applied in the direction of circuits, electrical components, photovoltaic power generation, etc., can solve the problems of insufficient micro-scale uniformity, insufficient purity of metal aluminum and silver, and affecting the macroscopic performance of aluminum and silver, etc., to achieve Good interface matching, good ohmic contact performance, and low metal recombination effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

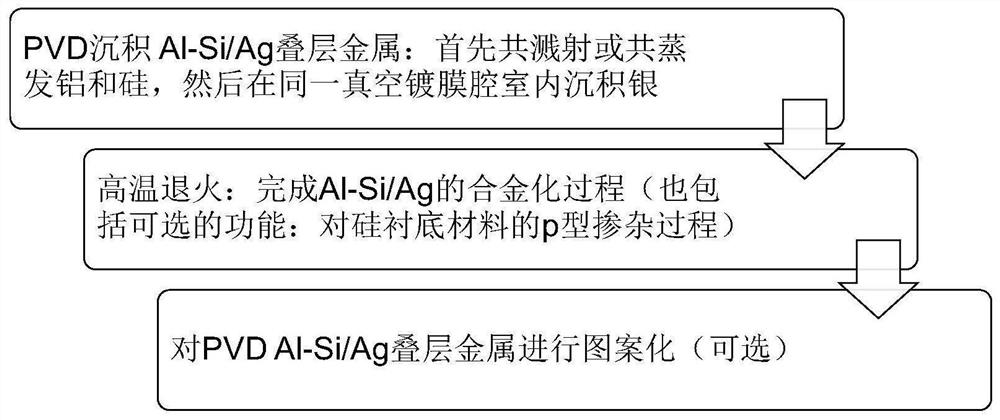

Method used

Image

Examples

Embodiment 1

[0028] Example 1 (Al-Si / Ag deposited by magnetron sputtering)

[0029] A1: Select sufficiently high-purity aluminum, silicon, and silver as targets, among which, the weight purity of Al is ≥99.999%, the weight purity of Si is ≥99.99%, and the weight purity of Ag is ≥99.99%.

[0030] A2: Place the silicon wafer and the sputtering target (aluminum, silicon and silver) to be coated on the base sample stage and the sputtering target in the sputtering coating equipment respectively, wherein the ratio of aluminum to silicon is 85wt.% Al and 15wt.% Si. The working area of the sputtering coating equipment is filled with high-purity argon (99.999%) as the sputtering gas.

[0031] A3: Turn on the vacuum pumps at all levels of the sputtering coating equipment, and vacuum through the vacuum pumps at all levels to make the background vacuum of the coating chamber reach 6 10 -5 Pa to meet the sputtering process conditions.

[0032] A4: Heat the temperature of the substrate sample stag...

Embodiment 2

[0035] Example 2 (Electron beam evaporation deposition of Al-Si / Ag)

[0036] B1: Select sufficiently high-purity aluminum, silicon and silver as evaporation materials, wherein the weight purity of Al is ≥99.995%, the weight purity of Si is ≥99.99%, and the weight purity of Ag is ≥99.99%.

[0037] B2: Open the door of the coating chamber, place the silicon wafer on the evaporating workpiece tray, put aluminum, silicon and silver in the evaporating crucible, and the ratio of aluminum to silicon is 88wt.% Al and 12wt.% Si, close the coating chamber Door.

[0038] B3: Turn on the vacuum pumps at all levels of the evaporation coating equipment, and vacuum through the vacuum pumps at all levels to make the background vacuum of the coating chamber reach 1·10 -3 Pa to meet the evaporation process conditions.

[0039] B4: Heat the temperature of the evaporation workpiece tray to 300-400°C, and keep the temperature constant for 2 minutes.

[0040] B5: E-beam evaporation coating: fir...

Embodiment 3

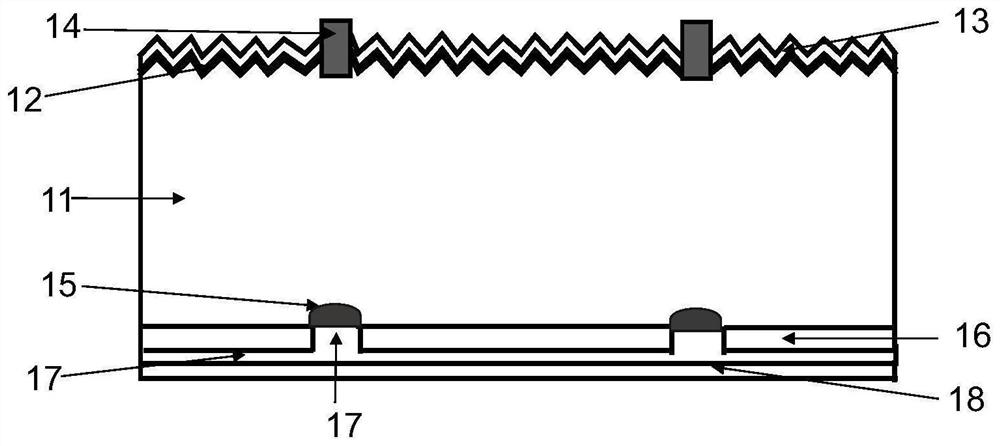

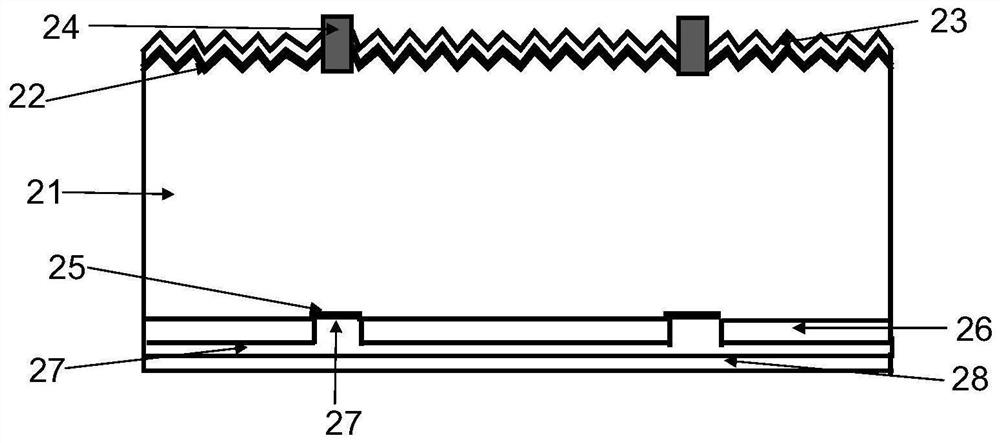

[0054] Example 3 discloses a preparation method for applying the Al-Si / Ag stacked metallization technology described in the present invention to a p-type PERC battery. The battery structure given in this example is as follows figure 2 shown. The specific battery preparation process is as follows.

[0055] C1: Select a 156mm*156mm (100) p-type monocrystalline silicon wafer with a resistivity of 1 Ω·cm.

[0056] C2: using an alkali texturing method to prepare a texturized surface with a random pyramid shape on the surface of the p-type silicon wafer. The process conditions are as follows: Potassium hydroxide with a mass concentration of 2-3% is used, the temperature is 70-75°C, and the texturing time is 5-7 minutes.

[0057] C3: A uniform n-type emitter junction is prepared on the front side of the p-type silicon wafer by the method of phosphorus oxychloride furnace tube diffusion, and the phosphorus surface doping concentration is 1.10 20 cm -3 , the sheet resistance is 9...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com