Intelligent release-type protein metal ion antibacterial nanoparticle and preparation method thereof

A nanoparticle and metal ion technology, which is applied in the functions of food ingredients, food ingredients containing natural extracts, and food forming, etc., can solve the problems of limited antibacterial activity and difficult to control the release efficiency of nanoparticle-encapsulated essential oils, and achieve high targets. The effect of tropism, good product stability and special product structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

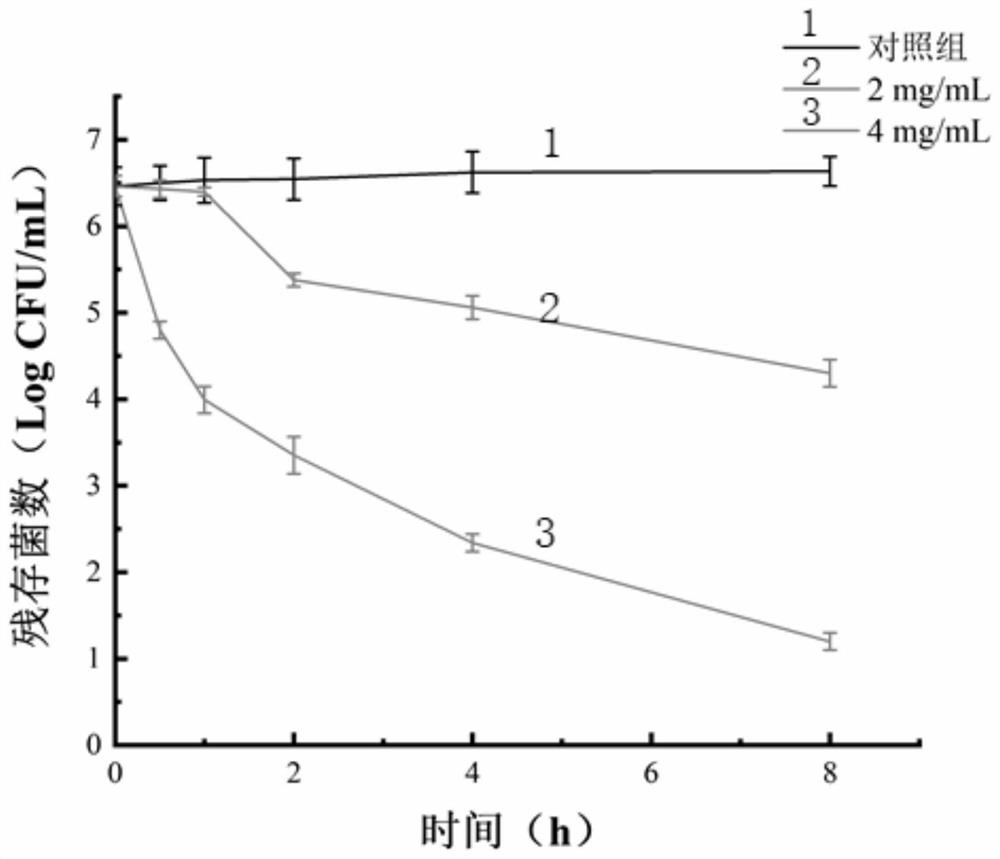

[0018] The bactericidal effect of embodiment 1 yarrow essential oil to escherichia coli O157:H7

[0019] 1 Experimental materials

[0020] Model strain: Escherichia coli O157:H7 (Escherichia coli O157:H7)

[0021] 2 Experimental methods

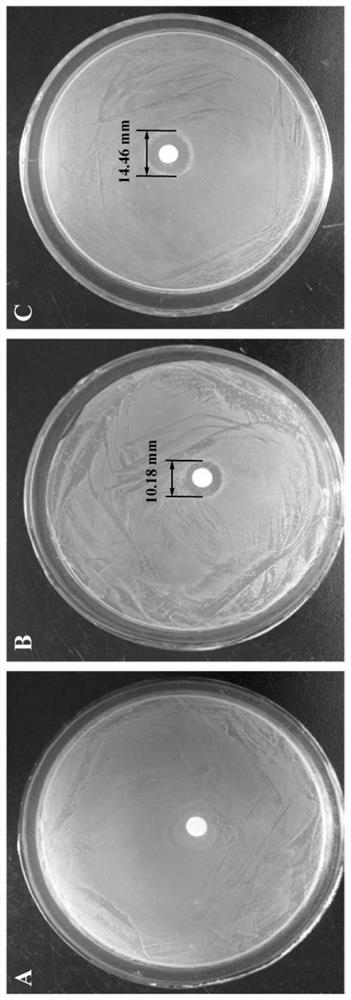

[0022] In phosphate buffered saline [Phosphate-Buffered Saline, PBS, 0.03mol / L, pH (7.2-7.4)] insert test bacterium Escherichia coli O157:H7 (10 5 -10 6 CFU / mL), add a certain concentration (2mg / mL, 4mg / mL) of yarrow essential oil, shake evenly, shake (120r / min) in a full-temperature air shaker at 37°C, and cultivate at 0h and 0.5h respectively. , 1h, 2h, 4h and 8h, take an appropriate amount of culture solution and carry out ten-fold serial dilution to 10 2 -10 3 CFU / mL, then pipette 100 μL of the diluted solution onto the solid medium, spread it evenly, and place it in a constant temperature and humidity incubator at 37°C for upside-down culture. After 48 hours, plate colonies were counted to evaluate the antibacterial activity of the...

Embodiment 2

[0025] Embodiment 2 Preparation of intelligent release protein metal ion antibacterial nanoparticles

[0026] 1 Experimental materials

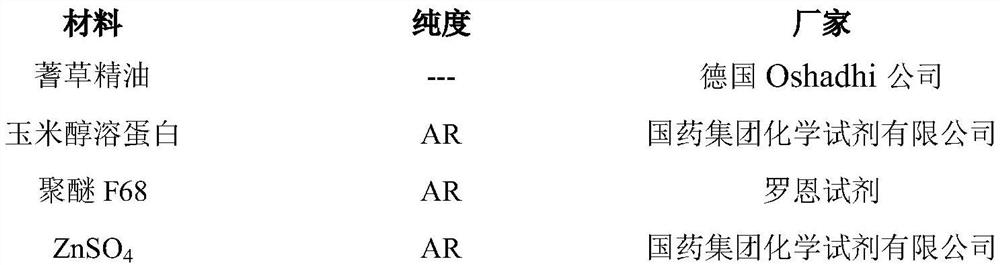

[0027]

[0028] 2 Experimental methods

[0029] The preparation steps of intelligent release protein metal ion antibacterial nanoparticles are as follows:

[0030] ① Preparation of solvent phase: Dissolve 0.2 g of zein in 10 mL of 85% ethanol aqueous solution, stir magnetically for 12 h, and add yarrow essential oil (4 mg / mL) after completely dissolving.

[0031] ② Preparation of non-solvent phase: 30 mL polyether F68 aqueous solution (1.5%, w / v).

[0032] ③ The solvent phase was transferred to the non-solvent phase, homogenized at 3000r / min for 3min, and then evaporated in an exhaust hood for 15h to remove ethanol.

[0033] ④Chelation: adjust the pH of the protein solution to 12 with 0.2mol / L NaOH, add ZnSO 4 (1mmol / L), 25 ℃ water bath shaking table shaking reaction for 1h, and finally dialyzed in a dialysis bag for 48h to prepare ant...

Embodiment 3

[0034] Embodiment 3 Characterization of intelligent release type protein metal ion antibacterial nanoparticles

[0035] 1 Experimental materials

[0036] Intelligent release protein metal ion antibacterial nanoparticles

[0037] 2 experimental equipment

[0038] Laser Particle Size Analyzer Nano ZS90 UK Malvern Instruments Ltd.

[0039] Gas chromatography-mass spectrometry (GC-MS) 6890GC / 5973NMSD Agilent Corporation of America

[0040] 3 Experimental methods

[0041] ①Using a laser particle size analyzer (Nano ZS90) to measure the particle size, polydispersity index (PDI) and Zeta potential of intelligent release protein metal ion antibacterial nanoparticles.

[0042]②Using GC-MS to determine the encapsulation efficiency of yarrow essential oil in antibacterial nanoparticles. Gas chromatography (GC) conditions are: DB-WAX elastic quartz capillary column (0.25mm×60m, film thickness 0.25μm), solvent delay is 10min. The injection volume was 1.0 μL, the split ratio was 1:20;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com