Black phosphorus-based composite negative electrode material, preparation method thereof and application of black phosphorus-based composite negative electrode material in metal secondary battery

A technology of negative electrode materials and composite materials, applied in the fields of material chemistry and electrochemistry, can solve problems such as difficulty in realizing reversible capacity, and achieve the effect of improving service life and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] Embodiment 1: the preparation of black phosphorus powder sample

[0064] Grind 500mg of black phosphorus block (prepared in the laboratory) into powder in a mortar, and then in a 50mL centrifuge tube, disperse it in 40mL of N,N-dimethylformamide (DMF) and heat at 600kW Ultrasonic treatment (Xinzhi Scientz-IID) under high power for 48 hours, suction filtration, washing and drying to obtain black phosphorus powder.

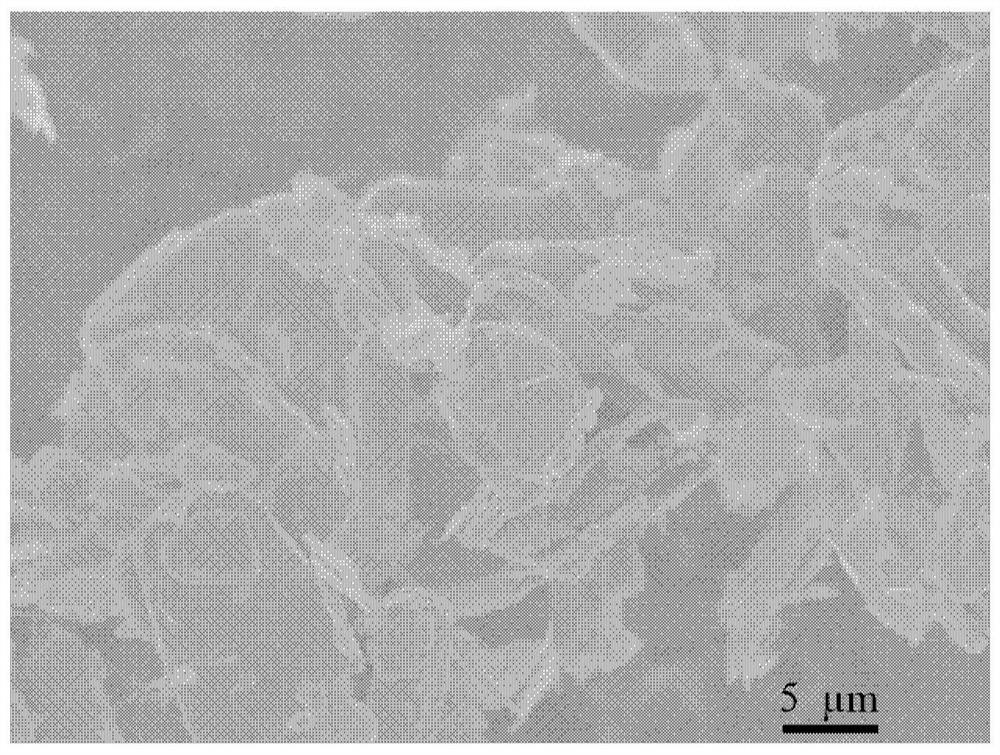

[0065] The black phosphorus powder that present embodiment 1 obtains is observed by scanning electron microscope (SEM), figure 1 Shown is a scanning electron microscope (SEM) photo of a black phosphorus powder sample obtained through ultrasonic treatment according to Example 1 of the present invention. Depend on figure 1 It can be seen that since black phosphorus is a layered two-dimensional material, its powder sample has a flake shape in the microscopic view, and the obtained black phosphorus powder has a uniform size of about 10 μm.

Embodiment 2

[0066] Embodiment 2: Preparation of black phosphorus-carbon modified material sample

[0067] In a ball mill (Fritcsh P7), 200 mg of the black phosphorus powder obtained in Example 1 and 50 mg of graphite powder (obtained from Alfa Aesar, 325 mesh) (the mass ratio of carbon to phosphorus is 4:1) were mixed under an argon atmosphere to Ball milling at a rotational speed of 550 rpm for 12 hours to obtain a black phosphorus-carbon modified composite material.

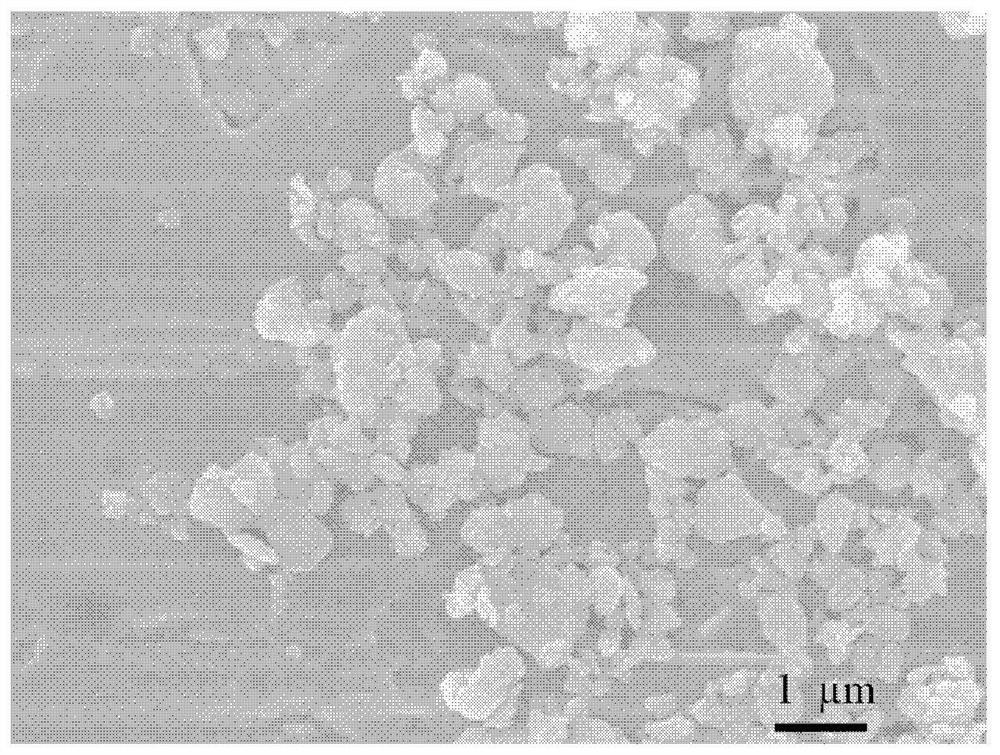

[0068] The black phosphorus-carbon modified composite material that present embodiment 2 obtains is observed by scanning electron microscope (SEM), figure 2 Shows a scanning electron microscope (SEM) photo of a black phosphorus-carbon modified composite material powder sample obtained through high-energy ball milling according to Example 2 of the present invention. The particle size ranges from 200 nm to 1 μm, and no layered The existence of black phosphorus indicates that the compounding is relatively uniform in ball mi...

Embodiment 3

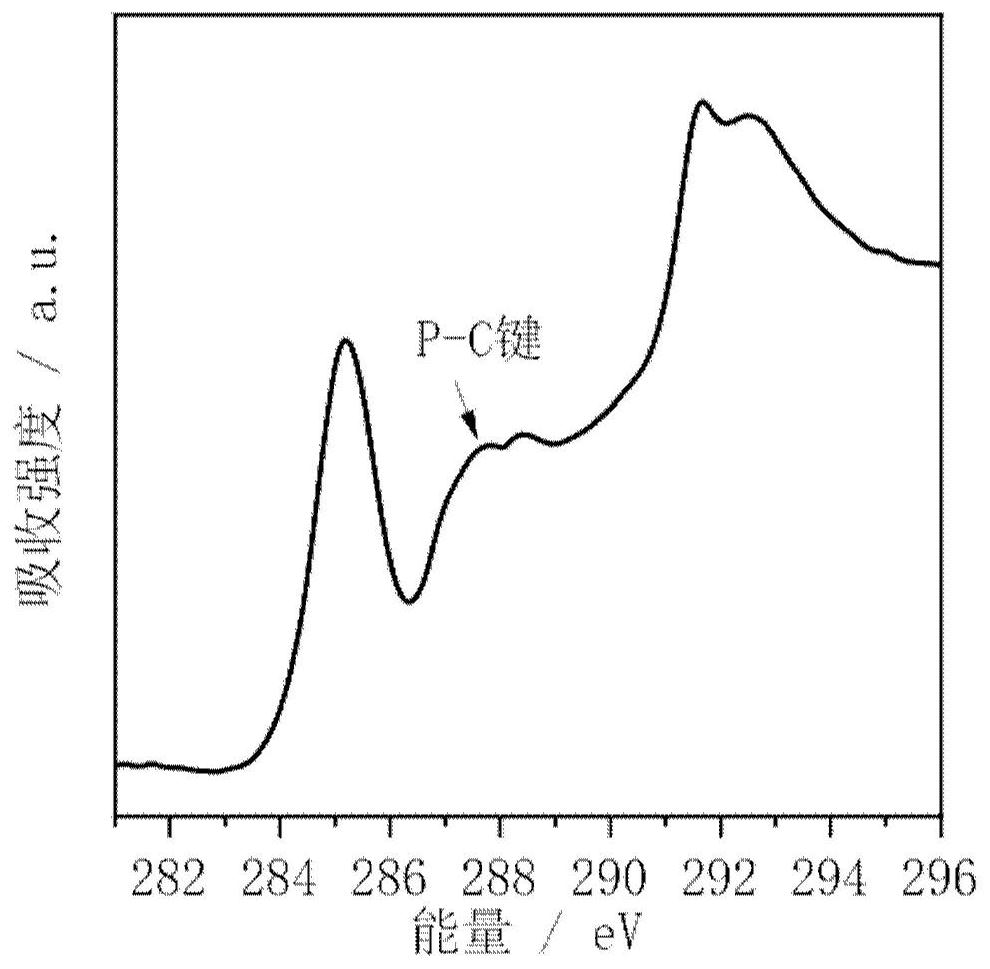

[0070] Example 3: Preparation of black phosphorus-carbon modified composite material coated with conductive polymer

[0071] In a 20mL sample vial bottle, 50mg of the black phosphorus-carbon modified composite material powder obtained in Example 2 was dispersed in 3.6mL of aniline (obtained from Aladdin Company) with a concentration of 3mg / mL and phytic acid ( obtained from Aladdin) in an aqueous solution at a concentration of 4 mg / mL and sonicated for 1 min. Then, 1.2 mL of another aqueous solution of ammonium persulfate (obtained from Sinopharm Reagent) with a concentration of 5 mg / mL was added to the mixed solution, and sonicated for another 1 minute. Subsequently, it was stirred for 5 h under an ice bath to complete the in situ polymerization of aniline. Finally, the reaction solution was suction-filtered, washed with water, and dried in a vacuum oven at 100° C., thereby obtaining the desired black phosphorus-graphite modified composite material coated with polyaniline (t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com