Preparation method of ethylene oxide

A technology of ethylene oxide and haloethanol, which is applied in chemical instruments and methods, molecular sieve catalysts, organic chemistry, etc., can solve the problems of difficult disposal of waste residues and pollution, and achieve the goals of improving catalytic performance, solving pollution problems, and improving catalytic performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] A preparation method of ethylene oxide, comprising the following steps:

[0033] (1) Haloalcoholization: Add molybdenum-containing hollow titanium-silicon molecular sieves, hydrogen peroxide, halogen element and dry gas into the reaction device, and carry out haloalcoholization reaction to obtain haloalcohols;

[0034] (2) Saponification: carry out saponification reaction with the haloethanol in step (1) and the hydroxide of alkali metal, and separate to obtain ethylene oxide and halide alkali metal salt.

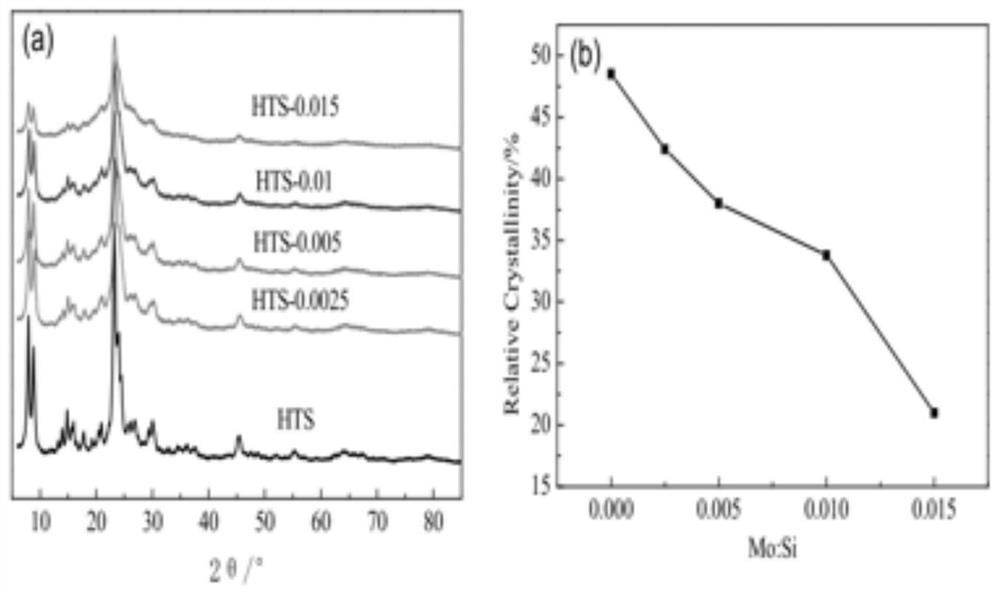

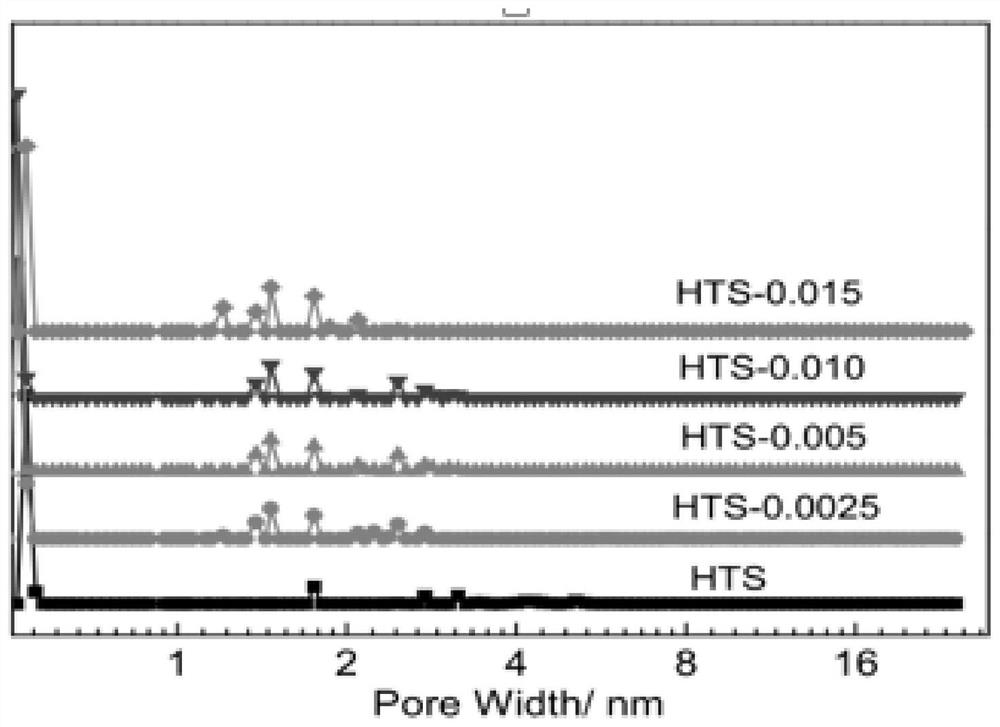

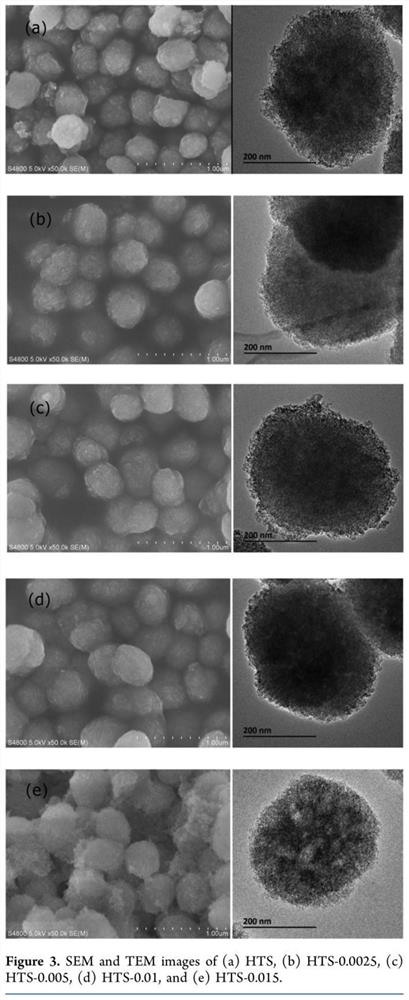

[0035] According to the present invention, the preparation method of the molybdenum-containing hollow titanium-silicon molecular sieve comprises the following steps:

[0036] (a) In the presence of an aqueous solvent, mix the silicon source with a structure-directing agent to fully hydrolyze the silicon source, then add molybdenum source, tetrabutyl titanate and phenylpropyltrimethoxysilane (PAPTMS) to obtain a precursor body solution;

[0037] (b) Pour the precurs...

Embodiment 1

[0064] A preparation method of ethylene oxide, comprising the following steps:

[0065] (1) Haloalcoholization: Add molybdenum-containing hollow titanium silicon molecular sieves, 70wt% concentration of hydrogen peroxide, chlorine and dry gas in the tower reactor, and carry out chloroalcoholization reaction at a temperature of 45°C to obtain chlorohydrin; wherein 70wt% concentration The flow rate of hydrogen peroxide, chlorine and dry gas should make the volume ratio of hydrogen peroxide, chlorine and dry gas about 1.1:0.5:1;

[0066] (2) Saponification: The chloroethanol obtained in step (1) is saponified with sodium hydroxide to obtain an ethylene oxide organic phase and sodium chloride solution; the saponification is carried out in a steel tower reactor, and the upper part is designed It is a sieve tray tower, steam enters from the bottom of the tower to blow out the generated crude ethylene oxide from the top of the tower, and the saponification temperature is controlled a...

Embodiment 2

[0074] Example 1 was repeated except that HTS-0.005 was used instead of HTS-0.0025 as catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com