Preparation method of nitrocellulose chromatographic membrane for rapid immunoassay, nitrocellulose chromatographic membrane and application thereof

A nitrocellulose and rapid immunization technology, which is applied in the field of preparation of nitrocellulose chromatography membranes, can solve the problems affecting detection efficiency, poor hydrophilicity and uniformity of nitrocellulose membranes, etc., and achieves improved production efficiency, good hydrophilicity and the like. properties and isotropic uniformity, and the effect of improving hydrophilicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The preparation method of the nitrocellulose chromatographic membrane that is used for rapid immunoassay, comprises the steps:

[0029] (1) Prepare casting solution: dissolve nitrocellulose, cellulose acetate and hydrophilic polymer polyethylene glycol and / or polyvinyl alcohol in a mixed solvent, then add surfactant, and finally add non-solvent water at 10 Stir evenly at a temperature of ~70°C, and after defoaming and filtering, the casting solution is obtained; first add a mixed solvent to fully dissolve nitrocellulose, cellulose acetate and hydrophilic polymers, and then add surfactants to assist in improving Hydrophilic;

[0030] Wherein, the mass ratio of cellulose acetate to nitrocellulose is 1:(10-10000), and in the casting solution, the parts by weight of each component are: 1-30 parts of nitrocellulose, 30-90 parts of mixed solvent 0.1-10 parts of hydrophilic polymer, 0.5-20 parts of non-solvent, 0.01-3 parts of surfactant;

[0031] The mixed solvent includes ...

Embodiment 1

[0042] This embodiment is a method for preparing a nitrocellulose chromatographic membrane for rapid immunoassay, comprising the following steps:

[0043] (1) prepare casting solution, casting solution is composed as follows:

[0044] Reagent weight percentage nitrocellulose 13.5% Cellulose acetate 0.5% polyvinyl alcohol 0.6% Methanol 42.6% propanol 13.6% Ethyl acetate 13.2% Sodium dodecyl sulfonate 0.1% water 15.9%

[0045] Dissolve nitrocellulose, cellulose acetate polymer and polyvinyl alcohol in mixed solvent methanol, propanol, ethyl acetate, then add surfactant sodium dodecyl sulfonate, and finally add non-solvent water, at 30 Stir evenly under the temperature condition of ℃, after defoaming and filtering, the casting solution is obtained;

[0046] (2) Scratch film: coating the casting solution on a polyester backing material with a thickness of 100 μm, and the thickness of the coated wet film is 500 μm;

...

Embodiment 2

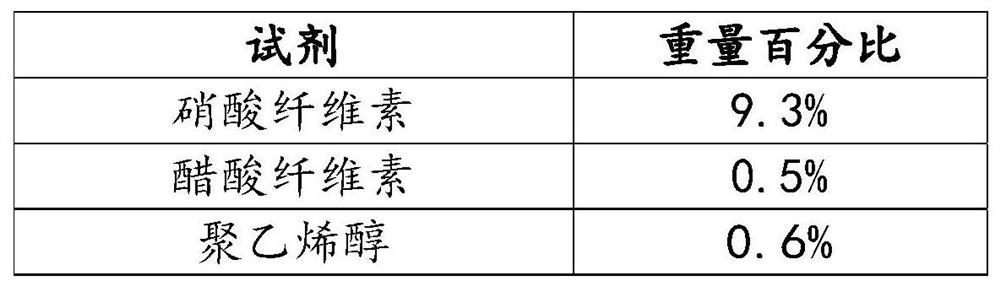

[0056] In this example, the preparation method of the nitrocellulose chromatographic membrane used for rapid immunoassay, the backing material in the film-forming formula is a polyethylene foam material with a thickness of 100 μm, and the composition of the casting solution is as follows:

[0057]

[0058]

[0059] Other conditions and parameters are the same as in Example 1.

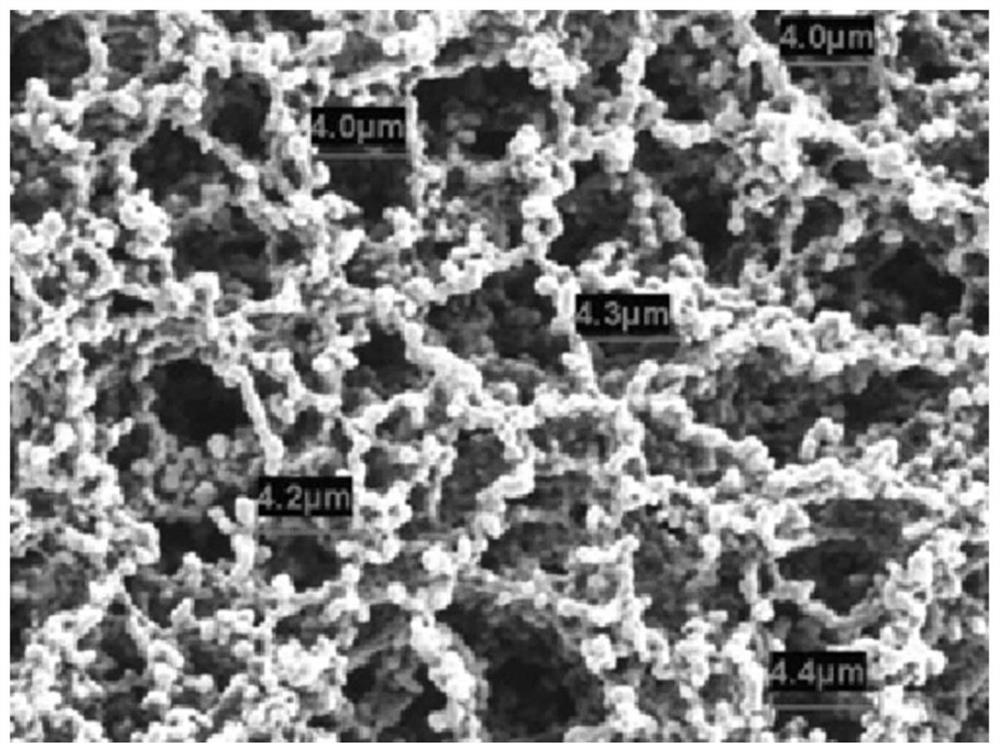

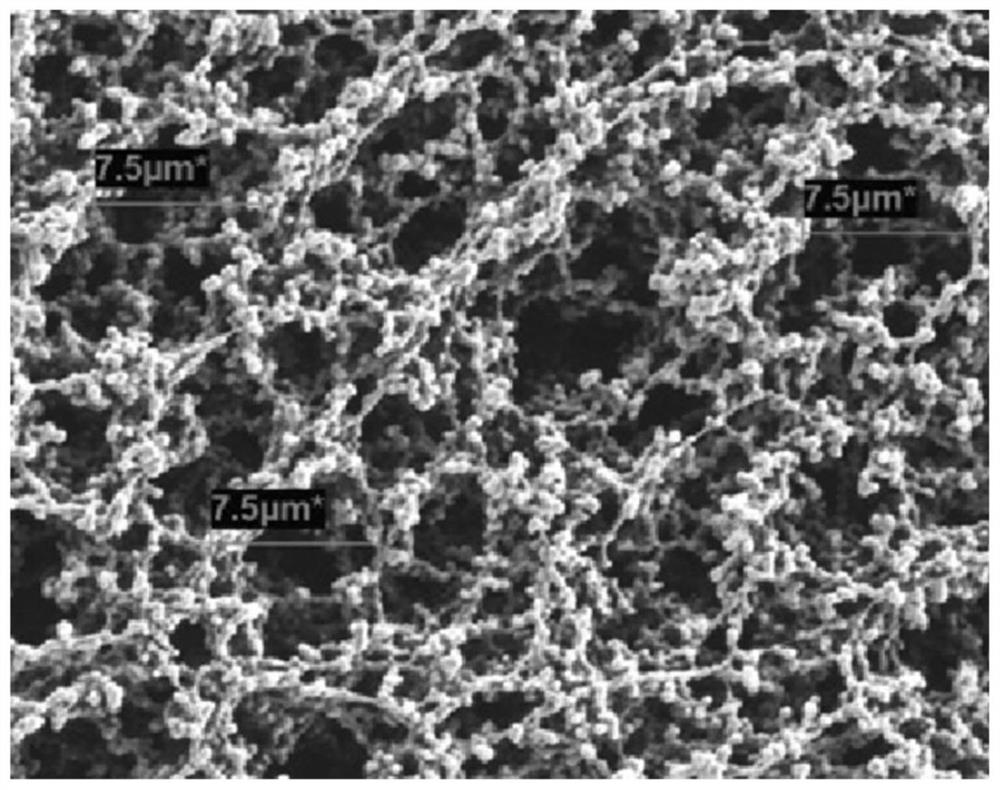

[0060] The electron micrograph of the surface topography of the film obtained in this embodiment can be found in figure 2 , The performance test results of the film are shown in Table 1.

[0061] The structure of the film prepared in this embodiment is uniform, and the porosity is very high, see figure 2 , which shows a part of the membrane prepared in this example. The average pore diameter of the membrane prepared in this example is 7.7 μm and the surface contact angle is 65° through computer calculation combined with all pore diameters, indicating that the membrane product is very hydrophili...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com