Micro-arc oxidation layer with spherical molybdenum disulfide and preparation method of micro-arc oxidation layer

A technology of micro-arc oxidation layer and molybdenum disulfide, which is applied in the direction of coating, liquid chemical plating, surface reaction electrolytic coating, etc., can solve the problem of uneven coating of solid lubricants, short action time of solid lubricants, and film layer In order to solve the problems such as the decrease of the binding force of the film base, the micro-arc oxidation layer of spherical molybdenum disulfide is uniform, strong in generalization, and good in sphericity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

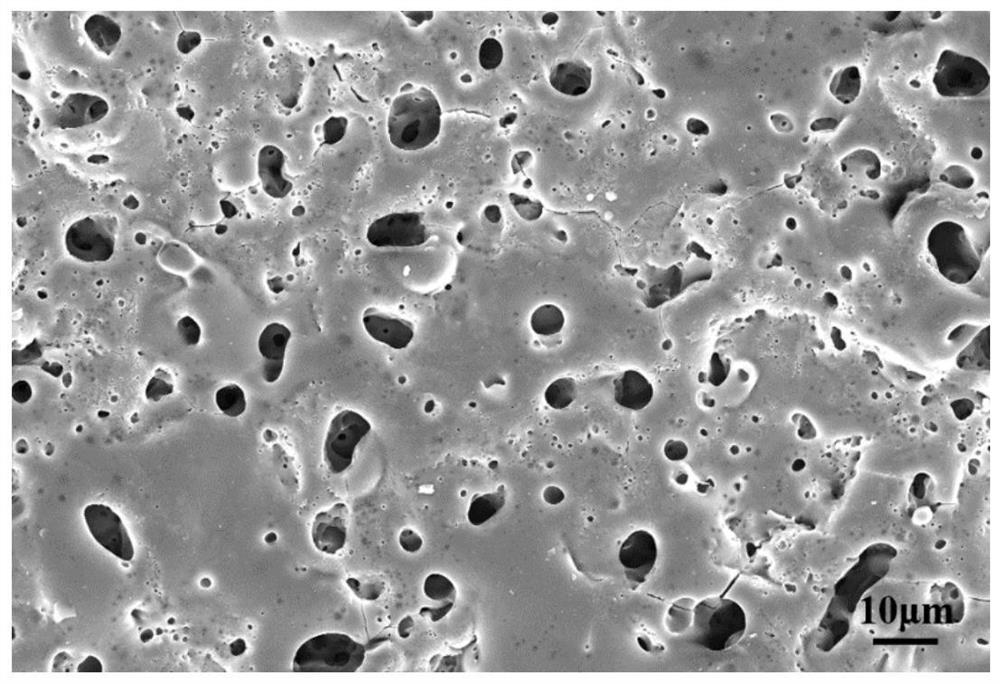

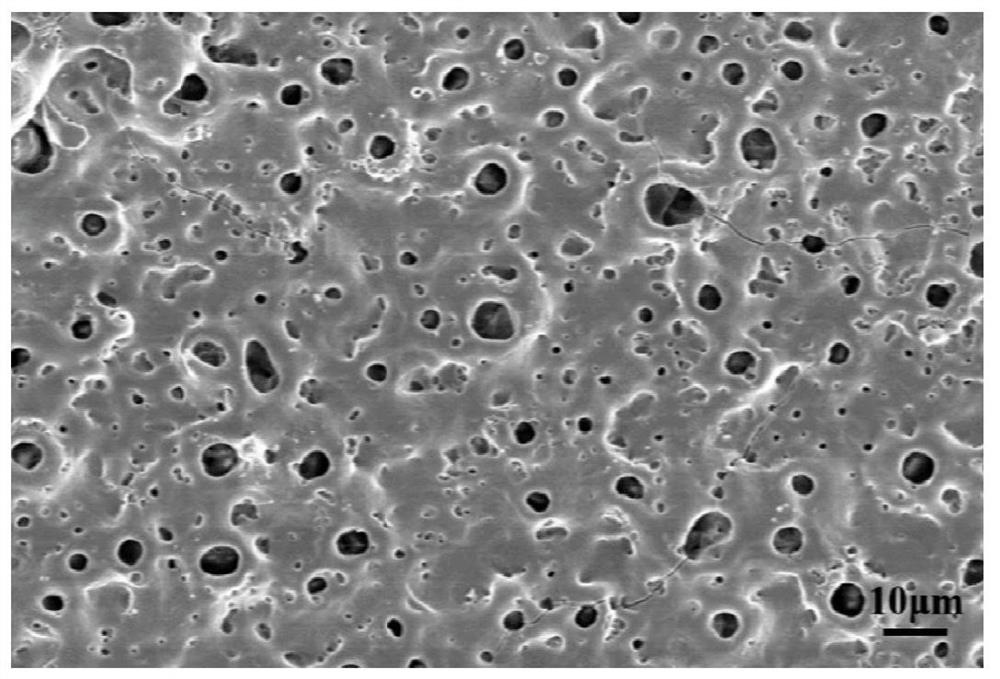

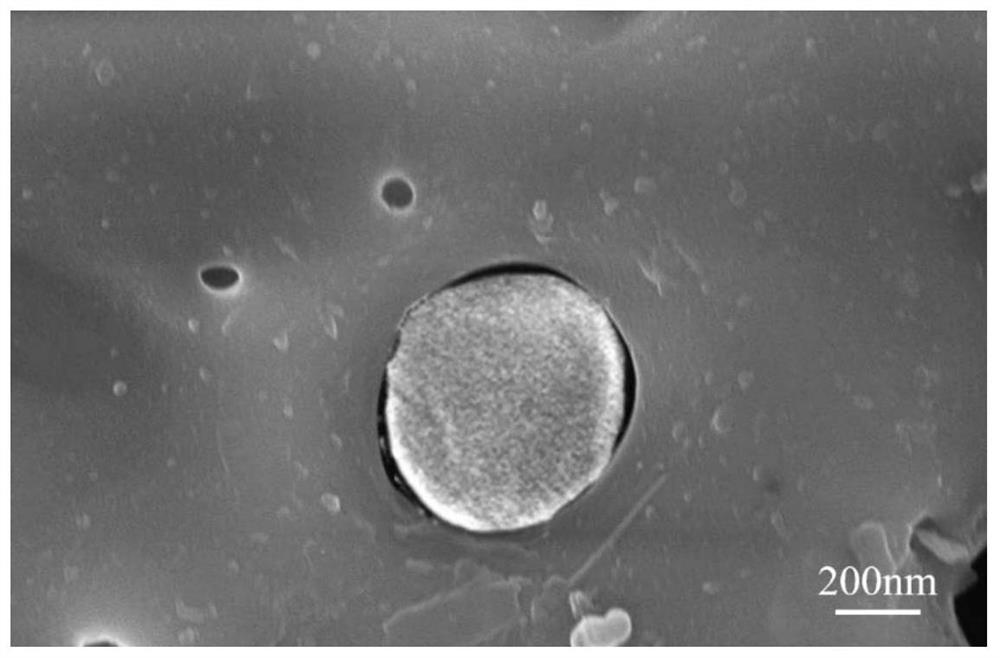

Image

Examples

Embodiment 1

[0035]Step 1. Polish the titanium alloy with 200#, 400#, 600#, 800#, 1000# sandpaper in sequence until the surface has no scratches, and then polish until the surface is smooth, as the matrix;

[0036]Adding sodium hexametaphosphate, potassium fluoride and sodium citrate to deionized water to obtain an electrolyte solution, each liter of electrolyte solution contains 6g sodium hexametaphosphate, 3g potassium fluoride, and 3g sodium citrate;

[0037]Inject the electrolyte into the electrolytic cell of micro-arc oxidation, place the titanium alloy substrate in the electrolyte as the anode, and place the stainless steel plate in it as the cathode, perform micro-arc oxidation, and prepare a micro-arc oxidation film on the surface of the titanium alloy. Wash and dry afterwards.

[0038]Step 2. Place the titanium alloy treated in step 1 in a reaction kettle containing a hydrothermal reaction solution, and then hydrothermally react the reaction kettle at 180°C for 2 hours. After the reaction, remov...

Embodiment 2

[0046]The preparation method of this embodiment is the same as that of embodiment 1, except that: in step 2, the PEG in the hydrothermal reaction solution is changed to PVP, the temperature of the hydrothermal reaction is 100° C., and the time is 36 hours.

Embodiment 3

[0048]The preparation method of this embodiment is the same as that of embodiment 1, except that the PEG in the hydrothermal reaction solution in step 2 is replaced with PVA.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com