Sludge ceramsite for heavy metal wastewater treatment, and preparation method

A wastewater treatment and sludge ceramsite technology, applied in water/sewage treatment, adsorption water/sewage treatment, water/sludge/sewage treatment, etc., can solve problems such as poor adsorption performance, achieve strong adsorption, no The effect of secondary pollution and strong adsorption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

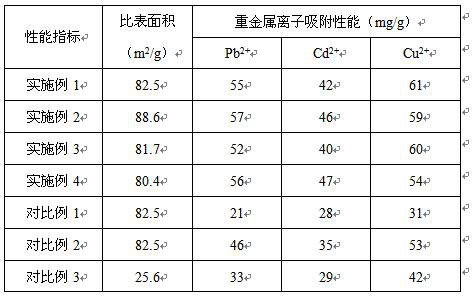

Examples

Embodiment 1

[0028] (1) Use river bottom mud as the main raw material, mix it evenly with fly ash, vermiculite powder, clay, ammonium bicarbonate, and water, then form the raw material into balls, and then sinter at high temperature to obtain porous ceramsite; the high-temperature sintering temperature is 1120°C, Sintering and heat preservation for 13min; the average particle diameter of porous ceramsite is 4mm; in the preparation of porous ceramsite, the mass ratio of river bottom mud, fly ash, water, vermiculite powder, clay, ammonium bicarbonate is 100:58:80:24: 23:1.2;

[0029] (2) Mix humic acid, isopropanol, sodium carbonate, sodium dodecylbenzenesulfonate, absolute ethanol, and deionized water evenly, add to a ball mill, and ball mill for 30 minutes at a speed of 50 rpm to obtain fine humic acid Slurry: In the slurry, the mass ratio of deionized water, nano humic acid, isopropanol, sodium carbonate, sodium dodecylbenzenesulfonate, and absolute ethanol is 100:50:3:1:0.5:4.

[0030] ...

Embodiment 2

[0033] (1) Use river bottom mud as the main raw material, mix it evenly with fly ash, vermiculite powder, clay, ammonium bicarbonate, and water, and then sinter the raw material into balls, and then sinter at high temperature to obtain porous ceramsite; the high-temperature sintering temperature is 1000°C, Sintering and heat preservation for 15min; the average particle size of porous ceramsite is 3mm; in the preparation of porous ceramsite, the mass ratio of river bottom mud, fly ash, water, vermiculite powder, clay, ammonium bicarbonate is 100:50:80:20: 20:1;

[0034] (2) Mix humic acid, isopropanol, sodium carbonate, sodium dodecylbenzenesulfonate, absolute ethanol, and deionized water evenly, add to a ball mill, and ball mill for 30 minutes at a speed of 50 rpm to obtain fine humic acid Slurry; in the slurry, the mass ratio of deionized water, humic acid, isopropanol, sodium carbonate, sodium dodecylbenzenesulfonate, and absolute ethanol is 100:50:3:1:0.5:2;

[0035] (3) A...

Embodiment 3

[0037](1) Use river bottom mud as the main raw material, mix it evenly with fly ash, vermiculite powder, clay, ammonium bicarbonate, and water, then form the raw material into balls, and then sinter at high temperature to obtain porous ceramsite; the high-temperature sintering temperature is 1200°C, Sintering and heat preservation for 10 minutes; the average particle size of porous ceramsite is 5mm; in the preparation of porous ceramsite, the mass ratio of river bottom mud, fly ash, water, vermiculite powder, clay, and ammonium bicarbonate is 100: 70: 80: 30: 25: 1.5;

[0038] (2) Mix humic acid, isopropanol, sodium carbonate, sodium dodecylbenzenesulfonate, absolute ethanol, and deionized water evenly, add to a ball mill, and ball mill for 30 minutes at a speed of 50 rpm to obtain fine humic acid Slurry; in the slurry, the mass ratio of deionized water, nano humic acid, isopropanol, sodium carbonate, sodium dodecylbenzenesulfonate, and absolute ethanol is 100:40:5:1:0.5:4.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com