Hydroxyl acrylic emulsion and preparation method and use method thereof

A technology of hydroxyacrylic acid and methyl methacrylate, which is applied in the field of hydroxyacrylic acid emulsion and its preparation, can solve the problems of poor mechanical stability and chemical stability, insufficient crosslinking density of the paint film, and difficulty in increasing the solid content, and achieve glossiness and high hardness, less aggregate content, and narrow particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

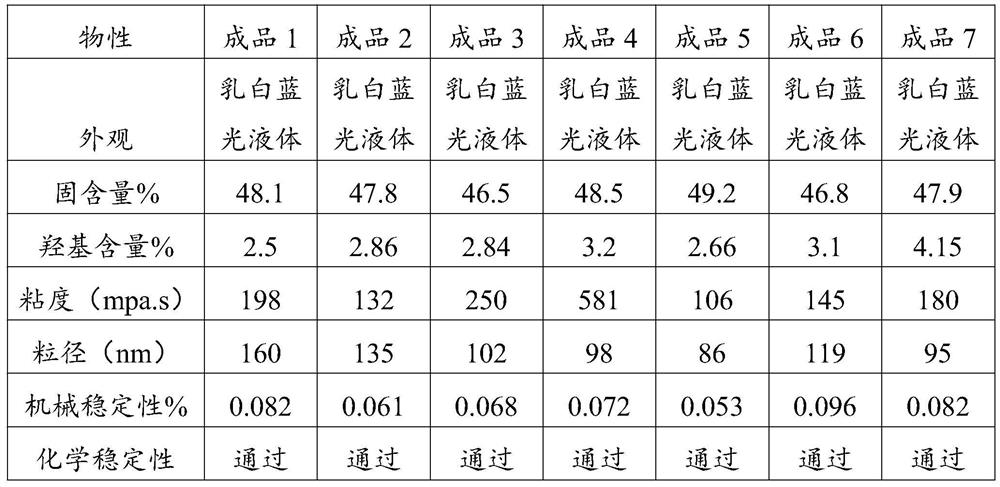

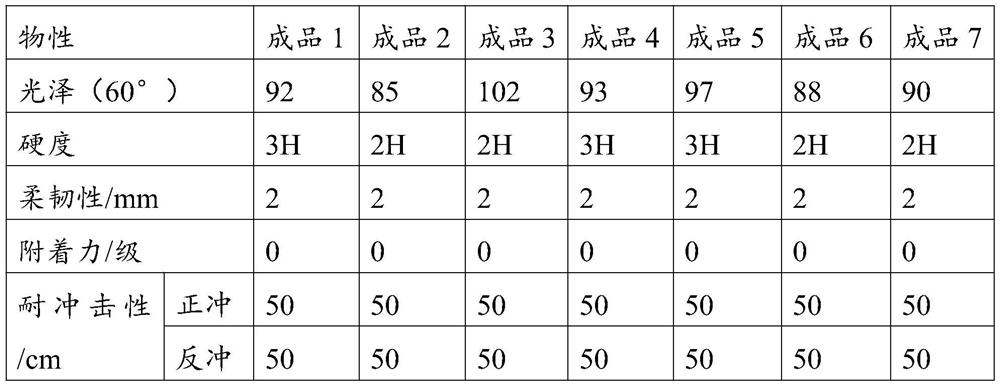

Examples

Embodiment 1

[0023] A hydroxyacrylic acid emulsion, comprising hydroxyacrylic acid particles, the hydroxyacrylic acid particles comprising a hard shell and a seed emulsion wrapped in the hard shell; the seed emulsion is an emulsified suspension containing a hydroxyacrylic acid structure, and the hard shell is A shell containing a hydroxyacrylic structure; the shell is also decorated with a water-based UV resin structure.

[0024] The hydroxyacrylic acid emulsion is formed by reacting the following materials in parts by weight: 100-200 parts of deionized water, 30-80 parts of methyl methacrylate, 15-70 parts of butyl acrylate, 1-20 parts of hydroxyacrylic acid Monomer, 0.5-5 parts of unsaturated carboxylic acid, 1-6 parts of functional monomer, 0.2-3 parts of emulsifier, 1-10 parts of water-based UV monomer, 0.3-2 parts of ammonium persulfate, 0.1 -0.8 part of sodium bicarbonate, 0.1-1 part of 3-mercapto butyl propionate, 0.3-1 part of diethylhydroxylamine and 0.1-0.5 part of asymmetric hin...

Embodiment 2

[0026] On the basis of Example 1, the hydroxyacrylic acid monomer is One or more of them, among them, R 1 -H or -CH 3 , R 2 for no 1 The value range is 1-10, n 2 The value range is 1-10, R 3 -H or -CH 3 .

[0027] The water-based UV monomer is a non-ionic self-emulsifying polyurethane modified UV resin with a functionality of 2-6.

[0028] The unsaturated carboxylic acid is one or more of acrylic acid, methacrylic acid, maleic acid and itaconic acid.

[0029] The functional monomer is one or more of trifluoroethanol methacrylate, triethoxysilane tetrafluoropropyl methacrylate, hexafluorobutyl methacrylate, and vinyltriethoxysilane.

[0030] The emulsifier is sodium dodecylbenzenesulfonate, sodium dodecylsulfonate, sodium polyoxyethylene ether sulfate, sodium dodecylbenzene diphenyl ether sulfonate, 2-acrylamide-2 methylpropane One or more of sodium sulfonate and alkylphenol polyoxyethylene ether.

[0031] The asymmetric hindered phenol antioxidant is BASF anti...

Embodiment 3

[0033] The preparation method of the hydroxyacrylic acid emulsion in above-mentioned embodiment 1-2, comprises the following steps:

[0034] S1: Prepare deionized water, methyl methacrylate, butyl acrylate, hydroxyacrylic acid monomer, unsaturated carboxylic acid, functional monomer, emulsifier, water-based UV monomer, ammonium persulfate, sodium bicarbonate, 3 -Butyl mercaptopropionate, diethylhydroxylamine and asymmetric hindered phenol antioxidants.

[0035] S2: 60-70% deionized water, 30-50% methyl methacrylate, 50-70% butyl acrylate, 25-45% hydroxyacrylic acid monomer, 30% -50% functional monomer, 30-70% emulsifier, 30-50% ammonium persulfate, 100% sodium bicarbonate and 100% butyl 3-mercaptopropionate, heat up to 50-70°C React for 2-4h to obtain seed emulsion.

[0036] S3: Prepare A solution with the remaining ammonium persulfate and the remaining deionized water; prepare the remaining methyl methacrylate, butyl acrylate, hydroxyl acrylic acid monomer, functional monom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com