Organic-inorganic nanoparticle composite water repellent, preparation method and application method thereof

A technology of inorganic nano-particles and water repellent, applied in textiles and papermaking, liquid-repellent fibers, wear-resistant fibers, etc., can solve the problems that silica is prone to agglomeration and cannot be uniformly dispersed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

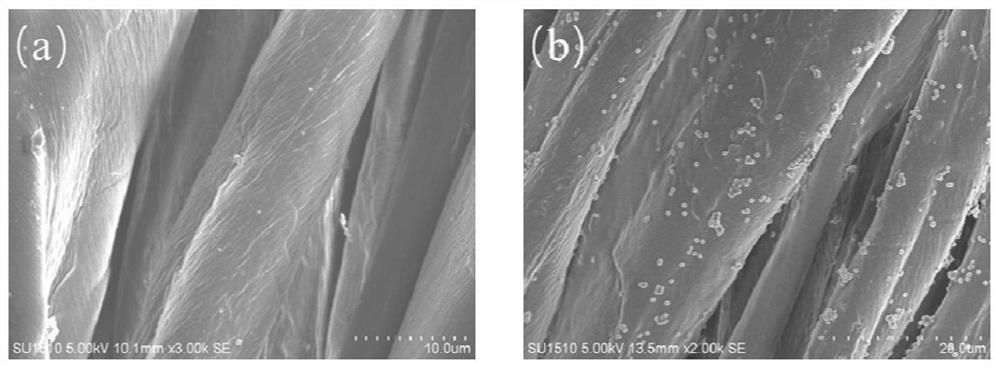

[0080] A kind of preparation of organic-inorganic composite nano particle water-repellent agent, comprises the following steps:

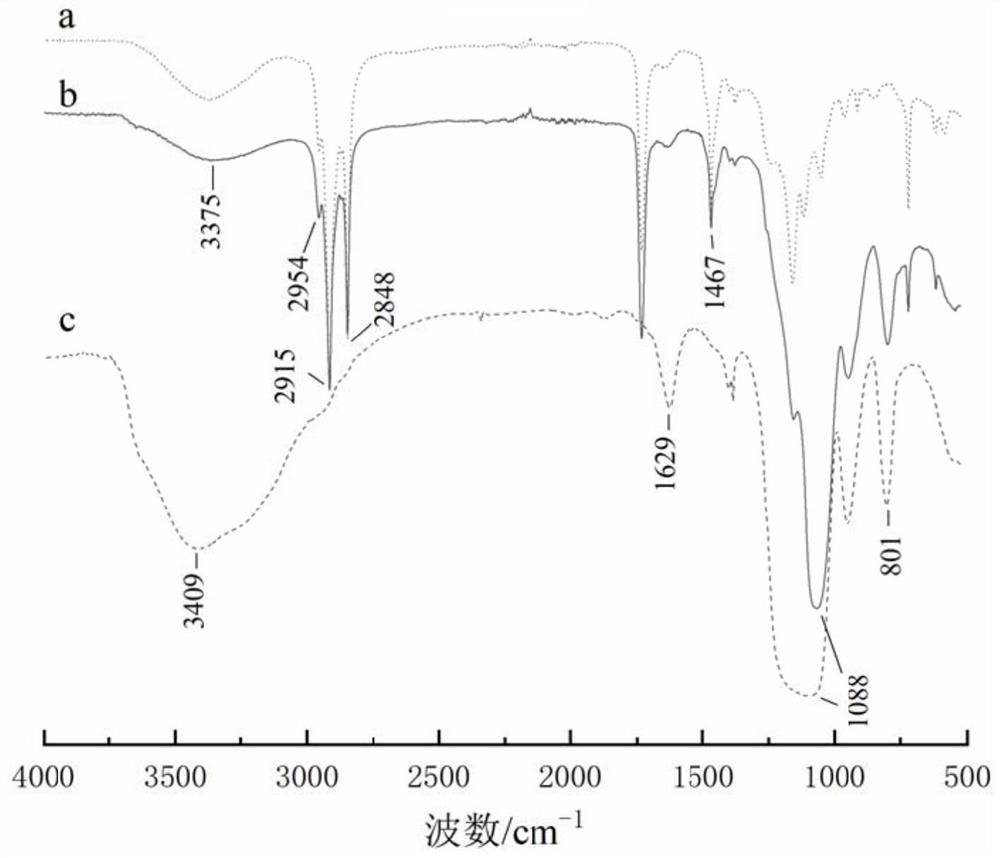

[0081] (1) Nano silica double bond modification:

[0082] Preparation of nano-silica: Under magnetic stirring, tetraethyl orthosilicate is dropped into a round-bottomed flask containing a mixed solution of ammonia and ethanol with a constant pressure funnel, and the stirring reaction is continued at room temperature, and the reaction system turns white. , centrifuge the reacted silicon dioxide dispersion, get silica gel at the bottom of the centrifuge tube, add appropriate amount of absolute ethanol again, ultrasonically disperse, centrifuge again, repeat 3 times, and vacuum dry to get nano silicon dioxide. Among them, the volume ratio of tetraethyl orthosilicate, ethanol, and ammonia water is controlled to be 1:34:2.5, and the reaction temperature is 30°C, so that nano-silica with a uniform particle size distribution of 100 nm can be obtained. Dis...

Embodiment 2

[0097] A kind of preparation of organic-inorganic composite nano particle water-repellent agent, comprises the following steps:

[0098] Referring to steps (1) and (2) in Example 1, the corresponding surface tertiary aminated silica was prepared.

[0099] Quaternization of polymer brush grafted nano silica:

[0100] The tertiary amine polymer brush grafted nano-silica was ultrasonically dispersed in 3 times the mass of absolute ethanol, and the halogenated hydrocarbon 4-bromo-1-butene containing double bond structure was added for quaternization. The halogenated hydrocarbon and nano The mass ratio of silicon dioxide is 1:100, magnetically stirred and reacted for 4 hours, poured into a large amount of ether for recrystallization, filtered by suction, and dried in vacuum to obtain quaternized nano-silica containing double bonds.

[0101] Preparation of organic-inorganic nanoparticle composite water repellent by copolymerization:

[0102] 1) Take quantitative octadecyltrimethyl...

Embodiment 3

[0109] A kind of preparation of organic-inorganic composite nano particle water-repellent agent, comprises the following steps:

[0110] Referring to steps (1) and (2) in Example 1, the corresponding surface tertiary aminated silica was prepared.

[0111] Quaternization of polymer brush grafted nano silica:

[0112] The tertiary amine polymer brush grafted nano-silica was ultrasonically dispersed in 3 times the mass of absolute ethanol, and the halogenated hydrocarbon 5-bromo-1-pentene containing double bond structure was added for quaternization. The halogenated hydrocarbon and nano The mass ratio of silicon dioxide is 1:50, and the reaction is carried out by magnetic stirring for 6 hours, poured into a large amount of ether for recrystallization, filtered by suction, and dried in vacuum to obtain quaternized nano-silica containing double bonds.

[0113] Preparation of organic-inorganic nanoparticle composite water repellent by copolymerization:

[0114] 1) Take quantitativ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Weft breaking strength | aaaaa | aaaaa |

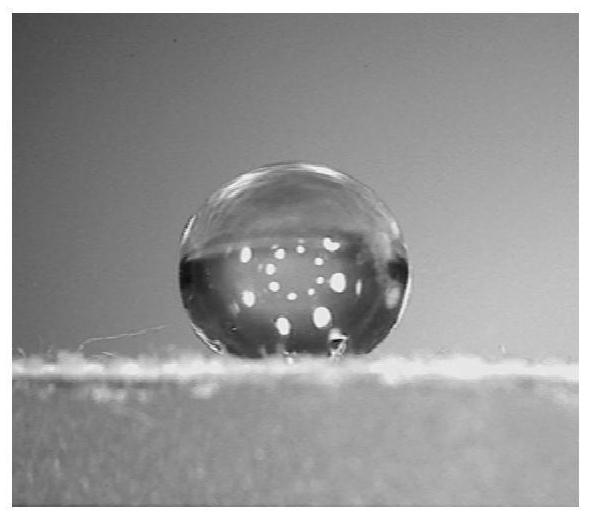

| Water contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com