Preparation method of cigarette end biochar material for selectively adsorbing ammonia in smoke

A selective and biochar technology, applied in the field of preparation of cigarette butt biochar materials, can solve the problems of costing money and material resources, failing to achieve ammonia adsorption, poor ammonia adsorption effect, etc., reducing pollution, improving adsorption, active sites, etc. added effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

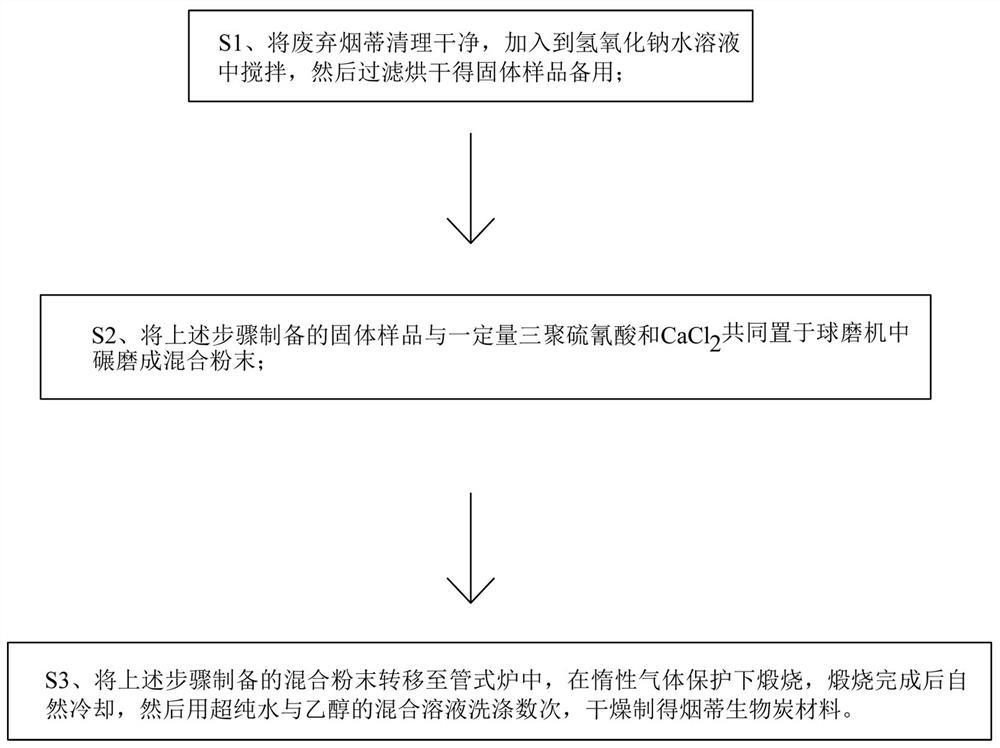

[0033] Clean up the shredded tobacco and paper on the surface of the discarded cigarette butts, add it to an aqueous sodium hydroxide solution at 25°C and stir for 1 hour, then filter and dry to obtain a solid sample for later use;

[0034] Weigh 2g of the solid sample prepared in the above steps with 1g of thiocyanuric acid and 1g of CaCl 2 Put them together in a ball mill and grind them into mixed powder;

[0035] The mixed powder prepared in the above steps was transferred to a tube furnace and calcined under the protection of nitrogen gas. The calcining temperature was 400° C. and the calcining time was 4 h. After the calcining was completed, it was naturally cooled, and then washed with a mixed solution of ultrapure water and ethanol for 5 Second, dry the sulfur-calcium double-doped biochar material.

Embodiment 2

[0037] Clean up the shredded tobacco and paper on the surface of the discarded cigarette butts, add it to an aqueous sodium hydroxide solution at 25°C and stir for 1 hour, then filter and dry to obtain a solid sample for later use;

[0038] Weigh 2g of the solid sample prepared in the above steps with 1g of thiocyanuric acid and 1g of CaCl 2 Put them together in a ball mill and grind them into mixed powder;

[0039] The mixed powder prepared in the above steps was transferred to a tube furnace and calcined under the protection of nitrogen gas. The calcining temperature was 500°C and the calcining time was 4 hours. Second, dry the sulfur-calcium double-doped biochar material.

Embodiment 3

[0041] Clean up the shredded tobacco and paper on the surface of the discarded cigarette butts, add it to an aqueous sodium hydroxide solution at 25°C and stir for 1 hour, then filter and dry to obtain a solid sample for later use;

[0042] Weigh 2g of the solid sample prepared in the above steps with 1g of thiocyanuric acid and 1g of CaCl 2 Put them together in a ball mill and grind them into mixed powder;

[0043] The mixed powder prepared in the above steps was transferred to a tube furnace and calcined under the protection of nitrogen gas. The calcining temperature was 600°C and the calcining time was 4 hours. Second, dry the sulfur-calcium double-doped biochar material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com