Polymer cement waterproof coating and preparation method thereof

A waterproof coating and polymer technology, applied in the field of waterproof coatings, can solve the problems of shortened service life of polymer cement waterproof coatings, attenuation of elongation at break of polymer waterproof coatings, and poor ability to bridge cracks, etc., to improve load stability. performance, improved acid resistance, and improved low temperature performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

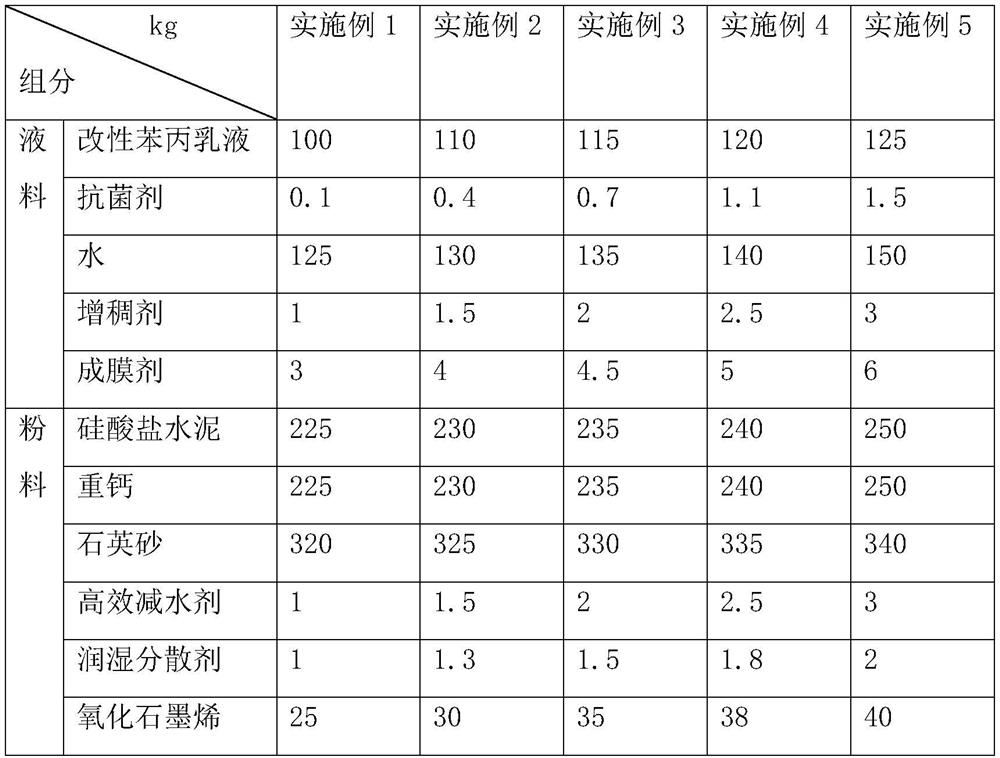

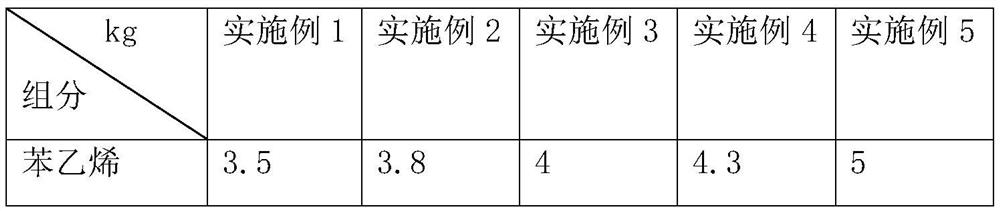

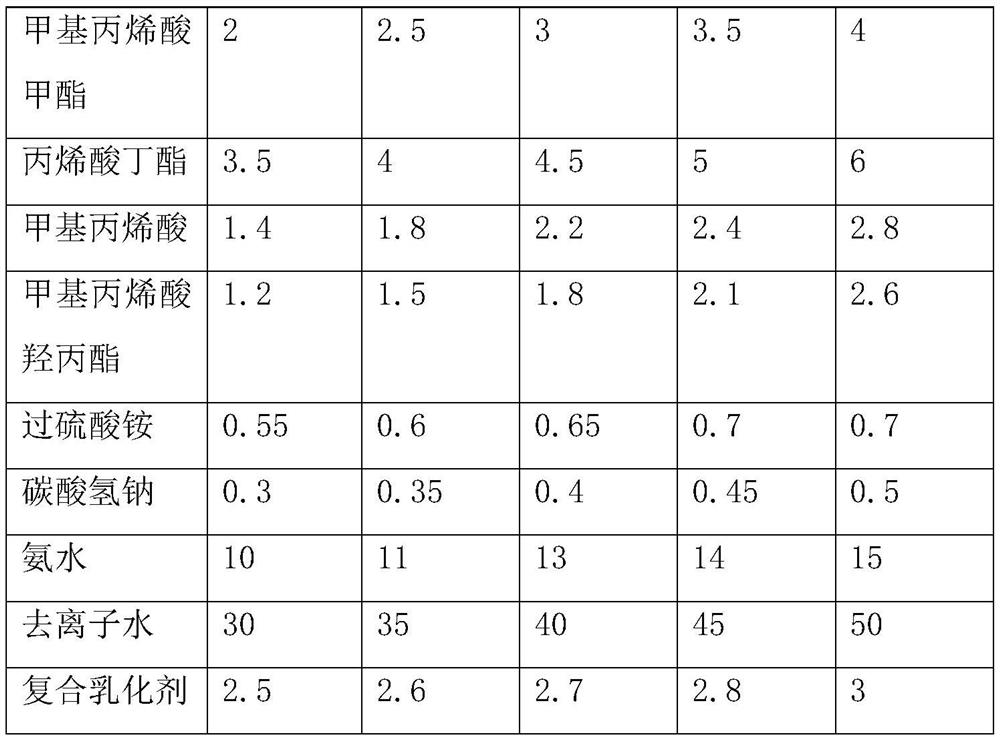

Examples

preparation example 1

[0040] Preparation Example 1: (1) Add stearic acid to the nano-calcium carbonate suspension after azeotropic distillation, make the temperature 85°C, stir for 40min, cool, vacuumize, and dry to constant weight at 100°C to obtain Modified nano-calcium carbonate, the mass ratio of stearic acid and nano-calcium carbonate suspension is 1:3; during azeotropic distillation, water and n-butanol and nano-calcium carbonate are boiled together, the mass ratio of water, n-butanol and your calcium carbonate The temperature is 1:1:0.6, and the temperature is gradually raised to 117°C;

[0041] (2) Add graphite to concentrated sulfuric acid, add sodium nitrate, stir and react at 80°C, add potassium permanganate, react at 30°C for 4h, adjust the pH to 7 with 30% sodium hydroxide, and ultrasonically 1h obtained graphene oxide solution, filtered and dried to obtain graphene oxide, the mass ratio of graphite, concentrated sulfuric acid, sodium nitrate and potassium permanganate was 1:1.3:0.6:0....

preparation example 2

[0043] Preparation Example 2: (1) Add stearic acid to the nano-calcium carbonate suspension after azeotropic distillation, make the temperature 88°C, stir for 35min, cool, vacuumize, and dry to constant weight at 103°C to obtain Modified nano-calcium carbonate, the mass ratio of stearic acid and nano-calcium carbonate suspension is 1:4; during azeotropic distillation, water and n-butanol and nano-calcium carbonate are boiled together, the mass ratio of water, n-butanol and your calcium carbonate The temperature is 1:1:0.7, and the temperature is gradually raised to 118°C;

[0044] (2) Add graphite to concentrated sulfuric acid, add sodium nitrate, stir the reaction at 85°C, add potassium permanganate, react at 33°C for 3h, adjust the pH to 7 with 30% sodium hydroxide, and ultrasonically 1.5h obtain graphene oxide solution, filter, dry, obtain graphene oxide, the mass ratio of graphite, concentrated sulfuric acid, sodium nitrate and potassium permanganate is 1:1.4:0.7:0.9;

[...

preparation example 3

[0046] Preparation Example 3: (1) Add stearic acid to the nano-calcium carbonate suspension after azeotropic distillation, make the temperature 90°C, stir for 30min, cool, vacuumize, and dry to constant weight at 105°C to obtain Modified nano-calcium carbonate, the mass ratio of stearic acid and nano-calcium carbonate suspension is 1:5; during azeotropic distillation, water and n-butanol and nano-calcium carbonate are boiled together, the mass ratio of water, n-butanol and your calcium carbonate 1:1:0.8, gradually increase the temperature to 120°C;

[0047] (2) Add graphite to concentrated sulfuric acid, add sodium nitrate, stir the reaction at 90°C, add potassium permanganate, react at 35°C for 2h, adjust the pH to 7 with 30% sodium hydroxide, and ultrasonically 2h obtained graphene oxide solution, filtered and dried to obtain graphene oxide, the mass ratio of graphite, concentrated sulfuric acid, sodium nitrate and potassium permanganate was 1:1.5:0.8:1;

[0048] (3) Heat g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com