Flexible carbon fiber composite electromagnetic shielding film and preparation method thereof

A composite electromagnetic and carbon fiber technology, applied in the direction of magnetic/electric field shielding, electrical components, etc., can solve the problems of complex preparation process and poor shielding performance, achieve good flexibility, high electromagnetic shielding performance, and improve the overall mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] A kind of preparation method of flexible carbon fiber composite electromagnetic shielding film of the present invention comprises the following steps:

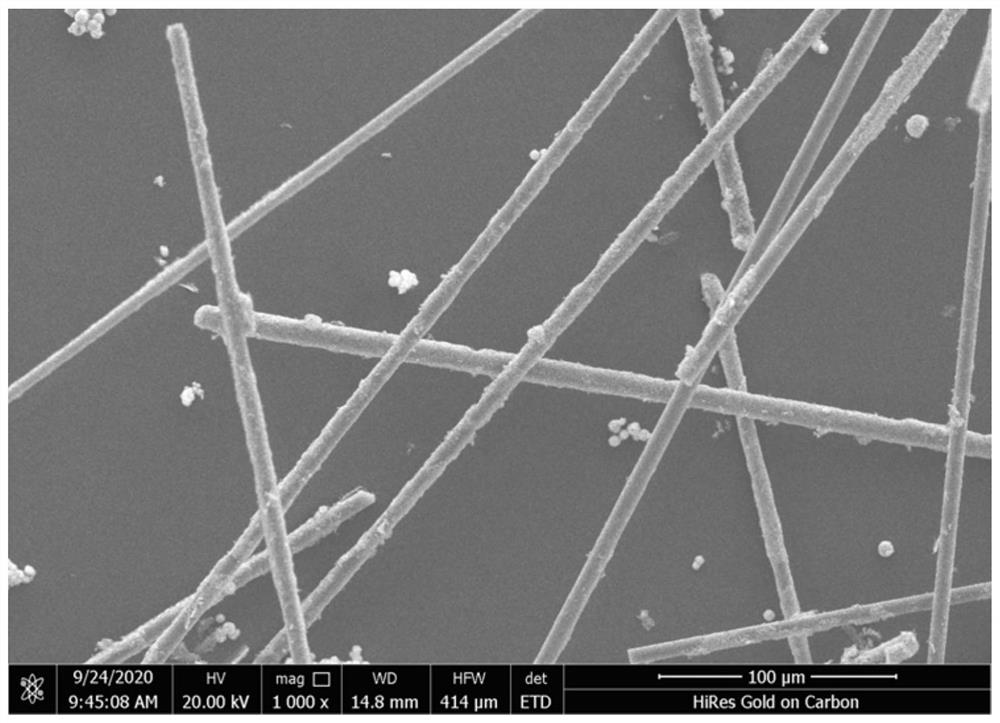

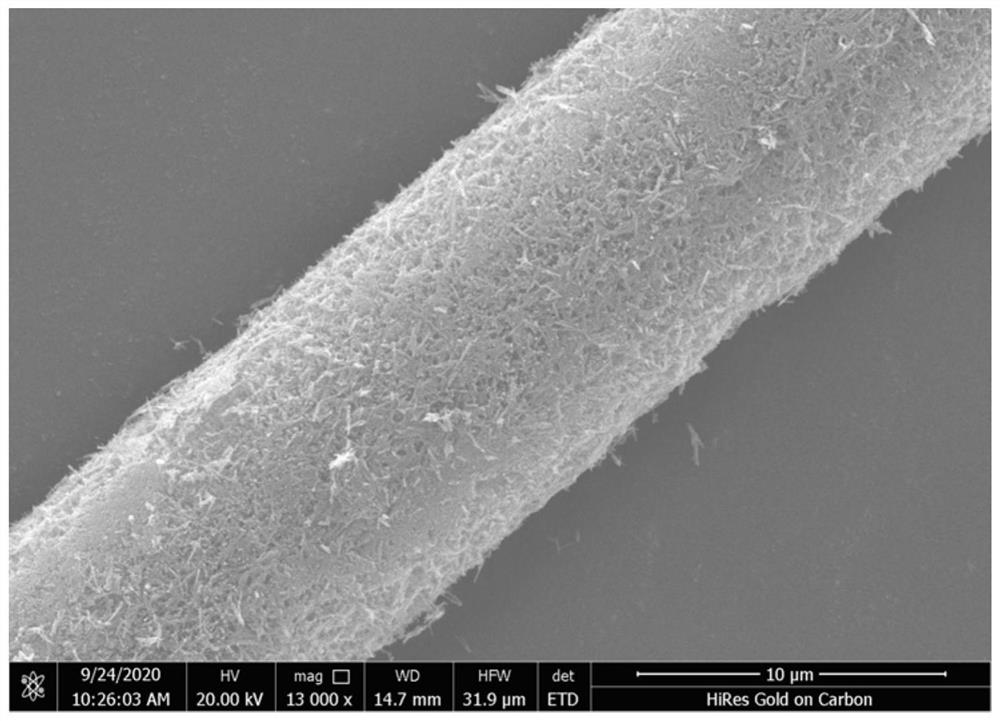

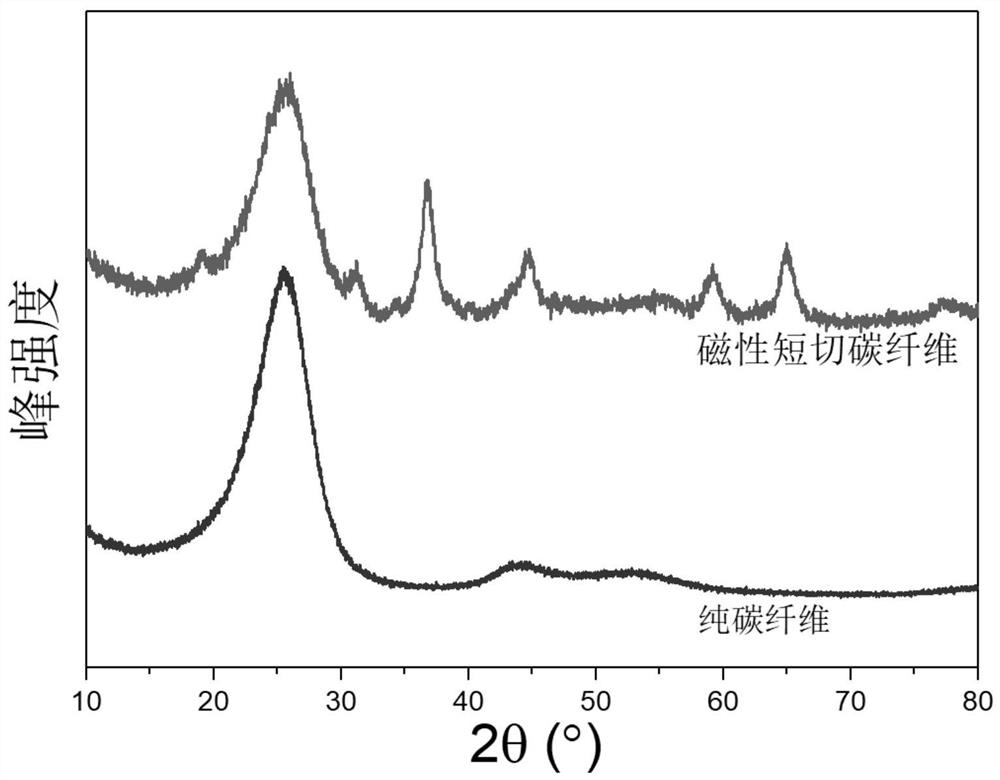

[0030] First, cobalt nitrate, urea and nickel nitrate are added to the solvent, stirred to fully dissolve, and the precursor solution is prepared; then the precursor solution and acidified chopped carbon fibers are added to the reactor for hydrothermal reaction, and the magnetic nanowires Uniform growth on the surface of chopped carbon fibers. After the reaction, the product is rinsed and dried, and then sintered at a temperature of 300-1000°C under nitrogen or air atmosphere to obtain magnetic chopped carbon fibers; then the magnetic chopped carbon fibers are subjected to suction filtration to obtain magnetic chopped carbon fiber membranes , and encapsulate the magnetic chopped carbon fiber film with polyimide resin or polyurethane resin, and finally obtain the flexible carbon fiber composite electromagnetic shielding ...

Embodiment 1

[0041] (1) Under room temperature conditions, fully dissolve 0.58g (2mmol) cobalt nitrate hexahydrate, 0.29g (1mmol) nickel nitrate hexahydrate and 0.72g (12mmol) urea in 35mL ethanol and deionized water (volume ratio=1: 1) was stirred and dissolved in the mixed solvent to obtain a precursor solution.

[0042](2) The chopped carbon fibers were treated with concentrated nitric acid at 30 °C for 8 h, rinsed with deionized water and dried in vacuum. The prepared precursor solution and the acidified chopped carbon fibers were transferred into a polytetrafluoroethylene-lined autoclave (50ml) for hydrothermal reaction, and the reaction was continued at 100°C for 12h. After the reaction is finished, rinse with deionized water and dry, and then sinter at a temperature of 300° C. in an air atmosphere to obtain magnetic chopped carbon fibers.

[0043] (3) At room temperature, add 4.08g (0.02mol) of 4,4'-diaminodiphenyl ether into a 250ml three-necked flask, then add 97.02g of N,N-dimet...

Embodiment 2

[0046] (1) Under room temperature conditions, fully dissolve 0.58g (2mmol) cobalt nitrate hexahydrate, 0.29g (1mmol) nickel nitrate hexahydrate and 0.72g (12mmol) urea in 35mL ethanol and deionized water (volume ratio=1: 1.5) was stirred and dissolved in the mixed solvent to obtain a precursor solution.

[0047] (2) The chopped carbon fibers were treated with concentrated nitric acid at 50°C for 5 h, rinsed with deionized water and dried in vacuum. The prepared precursor solution and the acidified chopped carbon fibers were transferred into a polytetrafluoroethylene lined autoclave (50ml) for hydrothermal reaction, and the reaction was continued at 120°C for 12h. After the reaction is finished, rinse with deionized water and dry, and then sinter at a temperature of 400° C. to obtain magnetic chopped carbon fibers.

[0048] (3) Add 4.08 g (0.02 mol) of 4,4'-diaminodiphenyl ether into a 250 ml three-necked flask at room temperature. Then add 61.08g of N,N-dimethylformamide and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com