Preparation method of liver-protecting and intestine-protecting fermented granule for litopenaeus vannamei

A pellet, fermentation type technology, applied in the field of feed and microbial fermentation, can solve the problem of probiotics being intolerant to high temperature and high pressure, and achieve the effects of good food attraction, strong growth-promoting ability and high bacterial enzyme content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

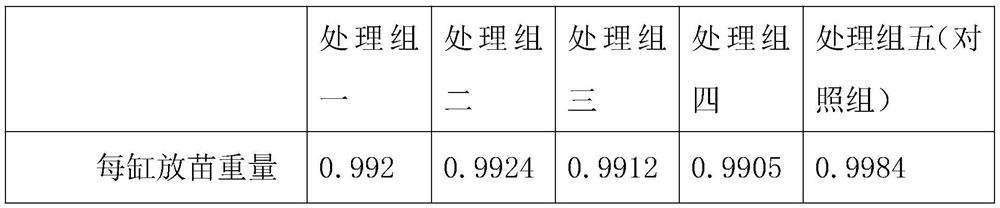

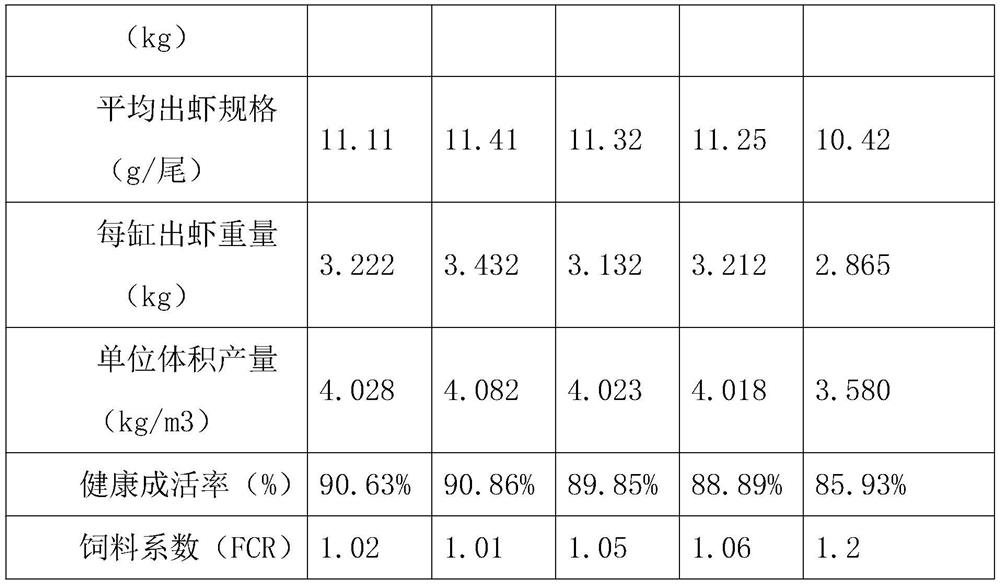

Embodiment 1

[0018] 126kg flour, 50kg corn germ meal, 17kg fish oil, 17kg soybean oil, 15kg soybean lecithin oil, 80kg fish meal, 50kg shrimp shell powder, 30kg shrimp paste, 237kg soybean meal, 40kg fermented soybean meal, 88kg rapeseed meal, 170kg cotton meal, 20kg diphosphate Calcium hydrogen, 40kg of fine stone powder, 2kg of vitamin premix, 10kg of mineral premix, 3.5kg of lysine, 2.5kg of methionine, 0.1kg of antioxidant, 2kg of antifungal agent are mixed evenly and then made into fully matured granules by high temperature and high pressure After feeding, when the temperature drops to 40°C, insert the enzyme-producing Bacillus licheniformis, Bacillus subtilis, Lactobacillus plantarum, Lactobacillus acidophilus, and Saccharomyces cerevisiae at a ratio of 2:10 of probiotic seed liquid: fully matured granules. The mixed bacterial liquid prepared according to a certain ratio is bagged and fermented for 96 hours to make a prawn fermented pellet feed with the function of protecting the live...

Embodiment 2

[0021] 116kg flour, 40kg corn germ meal, 17kg fish oil, 17kg soybean oil, 15kg soybean lecithin oil, 80kg fish meal, 40.6kg shrimp shell powder, 40kg shrimp paste, 257kg soybean meal, 30kg fermented soybean meal, 120kg rapeseed meal, 158kg cotton meal, 20kg phosphoric acid Calcium dihydrogen, 30kg fine stone powder, 2kg vitamin premix, 10kg mineral premix, 3kg lysine, 2.4kg methionine, 0.1kg antioxidant, 2kg antifungal agent are mixed evenly and then made into fully matured granules by high temperature and high pressure After feeding, when the temperature drops to 30°C, insert the enzyme-producing Bacillus licheniformis, Bacillus subtilis, Lactobacillus plantarum, Lactobacillus acidophilus, and Saccharomyces cerevisiae according to the ratio of probiotic seed liquid: fully matured granules of 3:10. The mixed bacterial liquid prepared according to a certain ratio is bagged and fermented for 168 hours to make a prawn fermented pellet feed with the function of protecting the liver...

Embodiment 3

[0024] 100kg flour, 60kg corn germ meal, 10kg fish oil, 10kg soybean oil, 15kg soybean lecithin oil, 100kg fish meal, 60kg shrimp shell powder, 20kg shrimp paste, 260kg soybean meal, 30kg fermented soybean meal, 60kg rapeseed meal, 80kg cotton meal, 20kg diphosphate Calcium hydrogen, 25kg of fine stone powder, 2kg of vitamin premix, 10kg of mineral premix, 1kg of lysine, 1kg of methionine, 0.1kg of antioxidant, 0.5kg of antifungal agent are mixed evenly, and then fully matured pellets are made by high temperature and high pressure Finally, when the temperature drops to 35°C, insert the enzyme-producing Bacillus licheniformis, Bacillus subtilis, Lactobacillus plantarum, Lactobacillus acidophilus, Saccharomyces cerevisiae etc. The mixed bacterial liquid prepared according to a certain ratio is bagged and fermented for 100 hours to make a prawn fermented pellet feed with the function of protecting the liver and intestines.

[0025] Butylated hydroxytoluene is selected as antioxid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com