Laying method for casting monocrystalline silicon seed crystal, crystalline silicon ingot and crystalline silicon ingot cutting and squaring method

A laying method and single crystal silicon technology, applied in the direction of crystal growth, single crystal growth, single crystal growth, etc., can solve the problem of weakening the competitiveness of cast single crystal silicon wafers and Czochralski single crystal silicon wafers, affecting the casting of single crystal silicon wafers Mass production and application, the reduction of the proportion of silicon ingots that can be sliced, etc., have achieved significant market application value, reduced battery efficiency levels, and narrowed the distribution range of photoelectric conversion efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

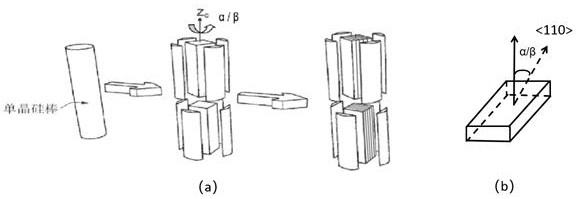

[0054] (1) Prepare a p-type single crystal silicon short round rod with a crystal orientation, a diameter of 240mm, and a length of 500mm grown by the pulling method. Connect the intersection of four ridgelines and the end face on the end face of the round rod to form a square, and place the square along the axis After rotating 45°, rotate the square by 5°. Cut along the four sides of the rotated square to obtain a 170mm*170mm*500mm single crystal square rod, cut the single crystal square rod longitudinally to obtain a 170mm*500mm*10mm long plate, and clean the long plate to obtain a single crystal silicon seed crystal long plate.

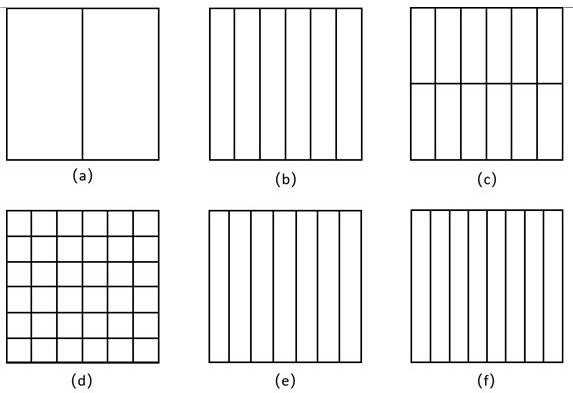

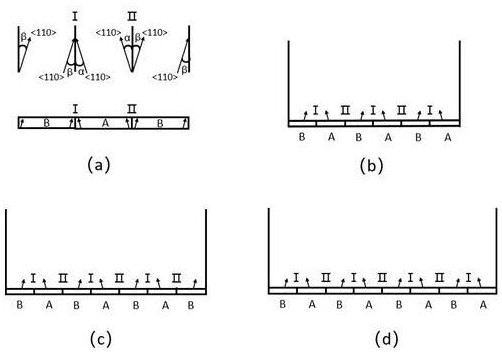

[0055] (2) Spray silicon nitride release agent on the inner surface of the crucible for ingot casting (inner bottom 1050mm*1050mm, square); remove the 10-15mm ingot remaining on the side wall of the crucible with 12 single crystal seed crystal long plates outside the safety clearance, follow the figure 1 (c) shows that the inner bottom of the cru...

Embodiment 2

[0058] (1) Prepare an n-type single crystal silicon short round rod with a crystal orientation, a diameter of 270mm, and a length of 1330mm grown by the pulling method. Connect the intersections of four ridgelines and the end face on the end face of the round rod to form a square, and place the square along the axis After rotating 45°, rotate the square by 5°. Cut along the four sides of the rotated square to obtain a 190mm*190mm*1330mm single crystal square rod, and longitudinally cut the single crystal square rod to obtain a 190mm*1330mm*15mm long plate. After cleaning the long plate, a single crystal silicon seed crystal long plate is obtained, which is marked as seed crystal A.

[0059] (2) Prepare n-type single crystal silicon short round rods with crystal direction, diameter 270mm, and length 1330mm grown by pulling method, connect four ridgelines on the end face of the round rod and the intersection points of the end face to form a square, and place the square along t...

Embodiment 3

[0063] (1) Prepare an n-type single crystal silicon short round rod with a crystal orientation, a diameter of 285mm, and a length of 1200mm grown by the pulling method. Connect the intersection of four ridgelines and the end face on the end face of the round rod to form a square, and place the square along the axis After rotating by 45°, rotate the square by 15°. Cut along the four sides of the rotated square to obtain a 200mm*200mm*1200mm single crystal square rod, and longitudinally cut the single crystal square rod to obtain a 200mm*1200mm*20mm long plate. After cleaning the long plate, a single crystal silicon seed crystal long plate is obtained.

[0064] (2) Spray silicon nitride release agent on the inner surface of the ingot crucible (inner bottom 1230mm*1230mm, square). Remove the 10-15mm ingot safety gap left between the 6 single crystal seed crystal long plates and the side wall of the crucible, according to figure 1 (b) shows that the inner bottom of the crucible...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com