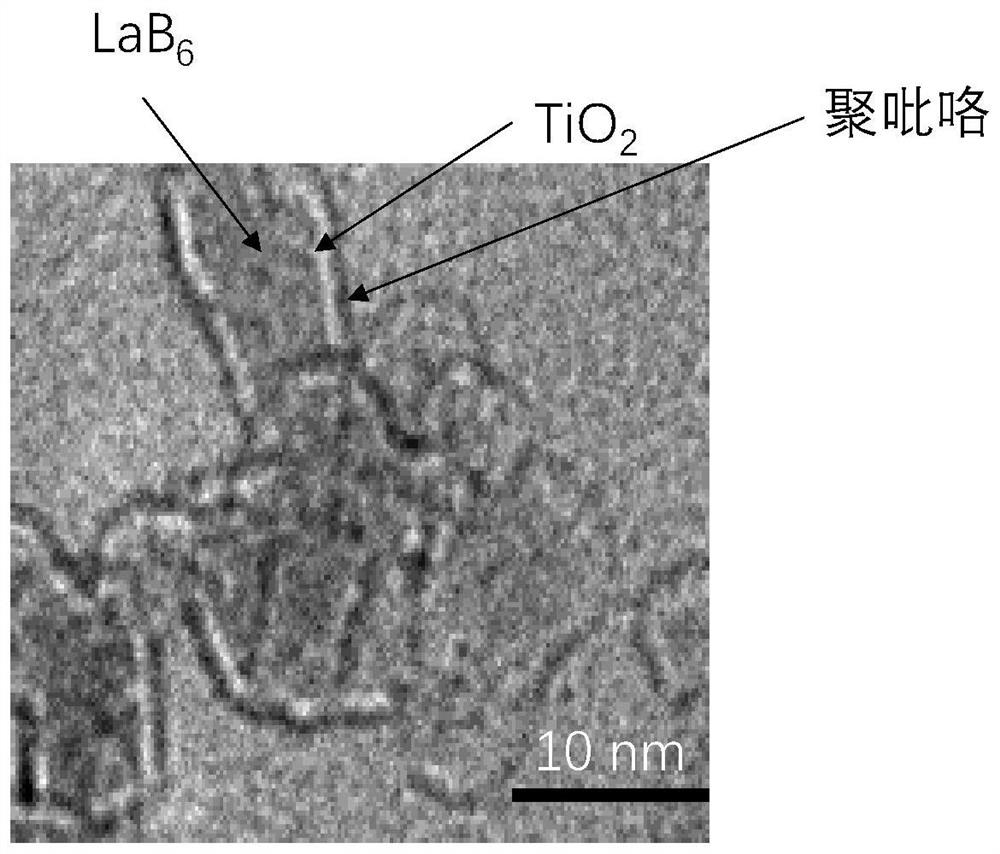

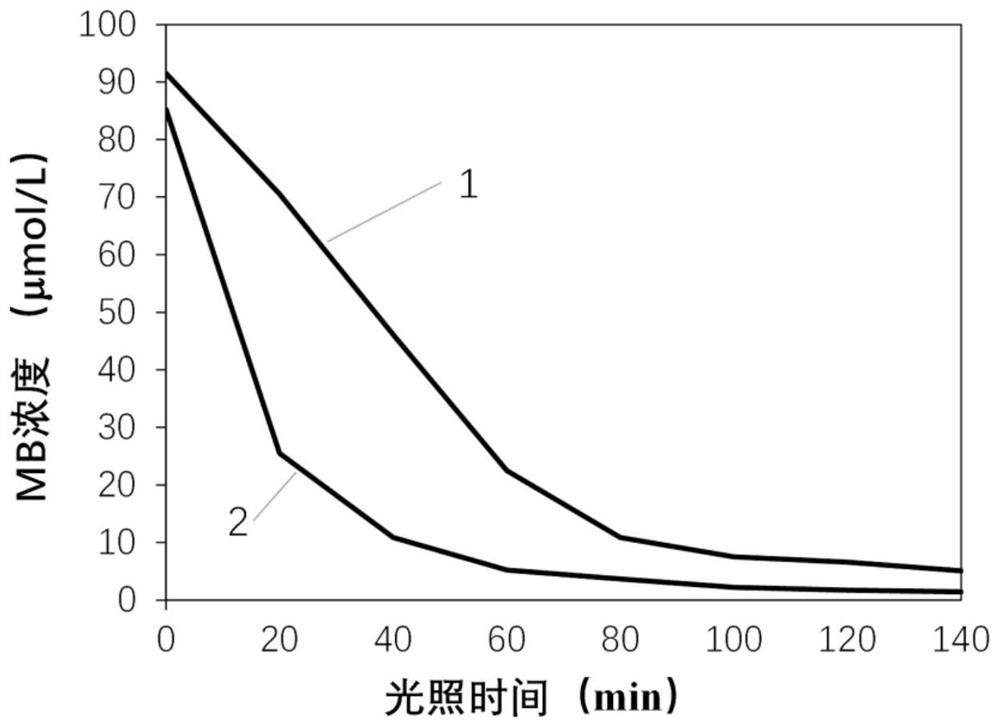

Preparation method of polypyrrole modified TiO2 coated LaB6 photodegradation catalyst

A polypyrrole and catalyst technology, applied in the field of polypyrrole-modified TiO2-coated LaB6 photodegradation catalyst and its preparation, can solve the problems that the hole separation efficiency is not as good as noble metal deposition and dye sensitization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Embodiment 1 takes lanthanum oxide as the synthesis of lanthanum boride of lanthanum source

[0050] Weigh 0.001 mole of lanthanum oxide (0.33g, containing 0.002 mole of lanthanum) and 0.012 mole of sodium metaborate according to the molar ratio of lanthanum, boron, and aluminum atoms as 1:6:7 (La:B:Al=1:6:7). (0.78g) and Al 0.014 mole (0.37g) powders were added to the ball mill jar, and after ball milling at a speed of 1000rpm for 12 hours, a mechanical mixture of lanthanum oxide, sodium metaborate and aluminum was obtained. The heating rate was heated from room temperature to 500°C and then kept for 2 hours; a mixture of lanthanum boride, metaaluminate and alumina was obtained through the following reaction:

[0051] La 2 o 3 +12NaBO 2 +14Al→2LaB 6 +12NaAlO 2 +Al 2 o 3

[0052] After cooling to room temperature, wash with 5wt% hydrochloric acid, centrifuge, wash with deionized water, filter, and vacuum-dry at 80° C. to obtain nanometer single crystal lanthanum...

Embodiment 2

[0053] Embodiment 2 takes lanthanum hydroxide as the synthesis of lanthanum boride of lanthanum source

[0054] According to the molar ratio of lanthanum, boron, and aluminum atoms as 1:6:7 (La:B:Al=1:6:7), weigh 0.001 mole (0.19g) of lanthanum hydroxide and 0.006 mole (0.39g) of sodium metaborate ) and Al 0.007 mole (0.18g) powder into the ball mill tank, after ball milling at 1000rpm for 12 hours to obtain a mechanical mixture of lanthanum oxide, sodium metaborate and aluminum, placed in the reactor, with a heating rate of 2 ° C / min from After heating at room temperature to 500°C, keep it warm for 2 hours; obtain a mixture of lanthanum boride, metaaluminate and aluminum hydroxide through the following reaction:

[0055] La(OH) 3 +6NaBO 2 +7Al→LaB 6 +6NaAlO 2 +Al(OH) 3

[0056] After cooling to room temperature, wash with 5wt% hydrochloric acid, centrifuge, wash with deionized water, filter, and vacuum-dry at 80° C. to obtain nanometer single crystal lanthanum boride....

Embodiment 3

[0057] Embodiment 3: take lanthanum carbonate as the synthesis of lanthanum boride of lanthanum source

[0058] Weigh 0.001 mole of lanthanum carbonate (0.46g, containing 0.002 mole of lanthanum) and 0.012 mole of sodium metaborate according to the molar ratio of lanthanum, boron, and aluminum atoms as 1:6:7 (La:B:Al=1:6:7). (0.78g) and Al 0.014 mole (0.37g) powders were added to the ball mill jar, and after ball milling at a speed of 1000rpm for 12 hours, a mechanical mixture of lanthanum oxide, sodium metaborate and aluminum was obtained. The heating rate is heated from room temperature to 500°C and then kept for 2 hours; CO is released through the following reaction 2 , to obtain a mixture of lanthanum boride, metaaluminate and alumina:

[0059] La 2 (CO 3 ) 3 +12NaBO 2 +14Al→2LaB 6 +12NaAlO 2 +Al 2 o 3 +3CO 2

[0060] After cooling to room temperature, wash with 5wt% hydrochloric acid, centrifuge, wash with deionized water, filter, and vacuum-dry at 80° C. to ob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com