Genetically engineered bacterium for producing muconic acid by taking lignin as raw material

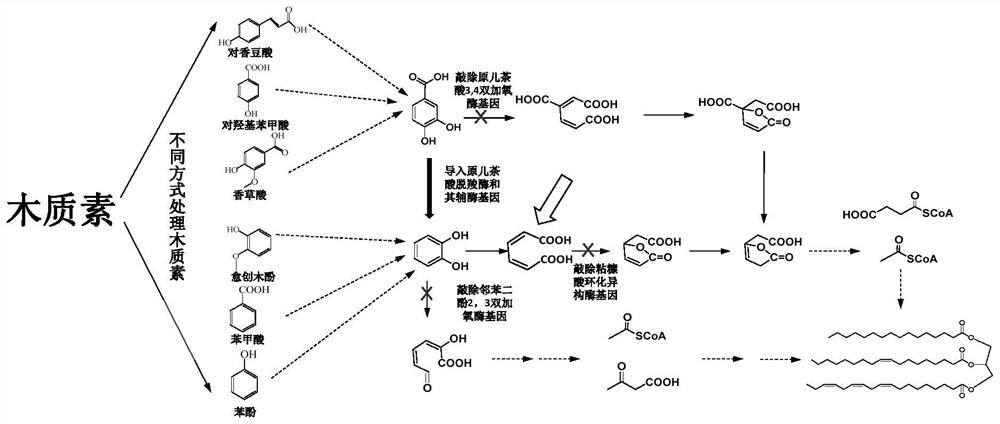

A technology of genetically engineered bacteria and lignin, applied in the field of genetic engineering, can solve the problem that mucofuroic acid cannot be accumulated, and achieve the effect of realizing high-value utilization and expanding the substrate spectrum.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] (1) Construction of suicide plasmid backbone pk18mob-pheS

[0030]Extract the Rhodococcus opacus PD630 genome, and design specific primers to clone the nucleotide fragment comprising the phenylalanyl-tRNA synthetase gene (AHK32253.1) and its own promoter, wherein the upstream primer is SEQ ID NO: 1: TACCCGGGGATCCTCTAGATGCGGTCCTCGACAGCATCAGCG; the downstream primer is SEQ ID NO: 2: AACGACGGCCAGTGCCAAGCTTATTGCGCTACTCGCACGTCTGC according to the following system for PCR reaction:

[0031] 5×Reaction buffer 10.0 μL dNTPs (10mM) 1.0 μL Upstream primer SEQ ID NO:1 (10μM) 1.0 μL Downstream primer SEQ ID NO:2 (10μM) 1.0 μL Rhodococcus opacus PD630 genome 1.0 μL Taq enzyme (5U / μL) 1.0 μL wxya 2 o

35.0μL overall system 50μL

[0032] The reaction system was carried out according to the following procedure: pre-denaturation at 95°C for 3 min; denaturation at 95°C for 30 s, annealing at 55°C for 30 s, extension at 7...

Embodiment 2

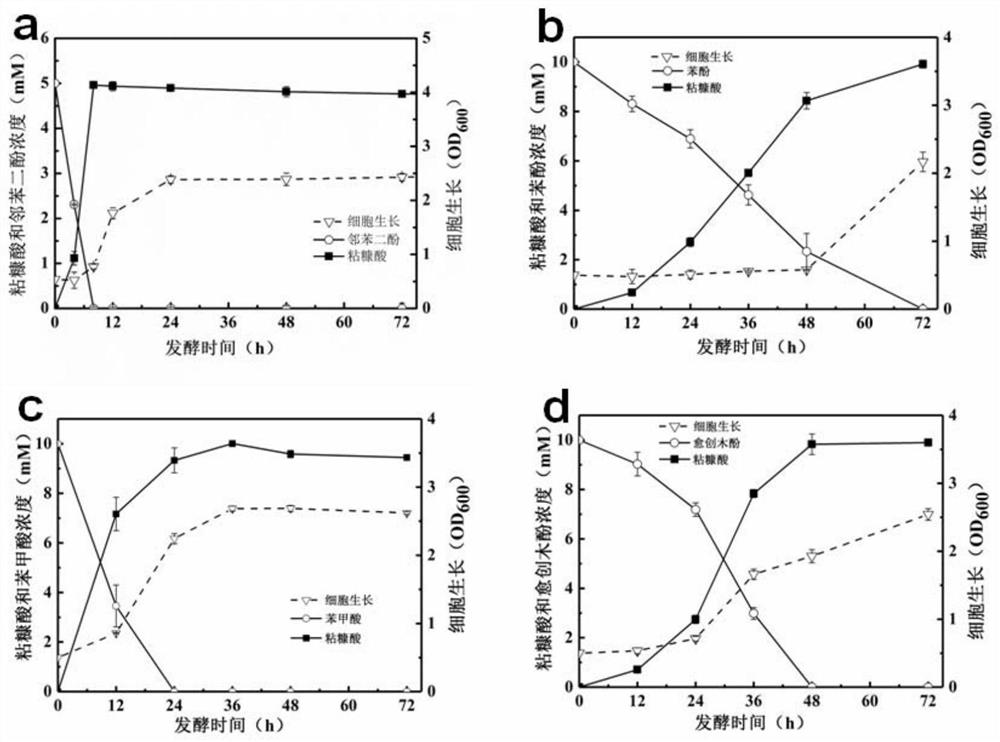

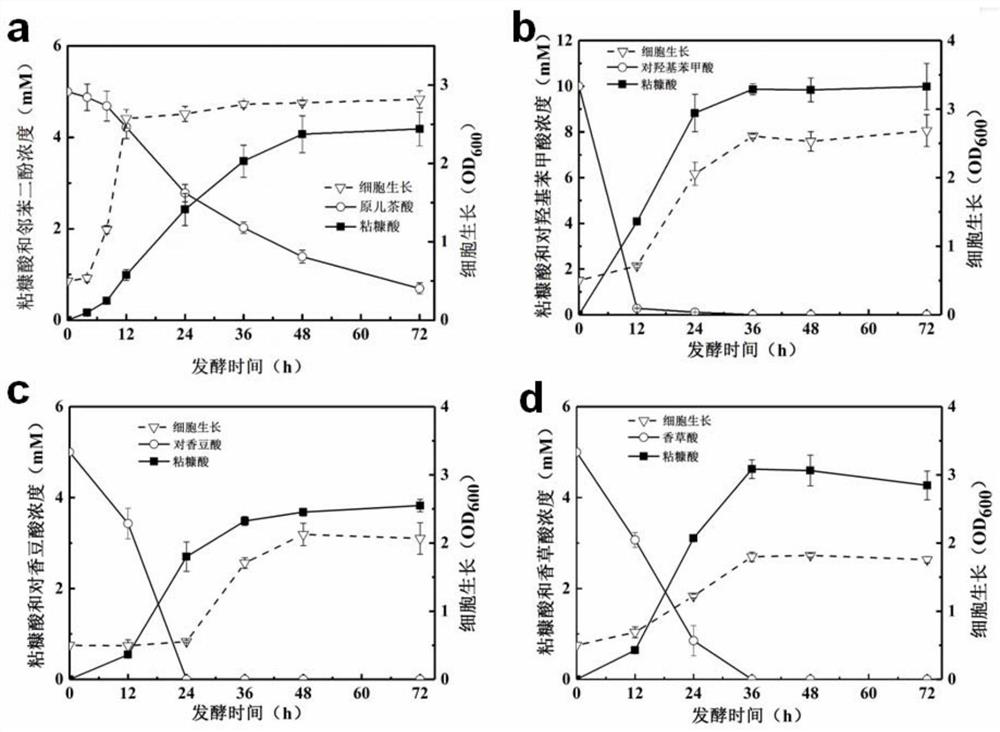

[0053]Embodiment 2 takes commercially available lignin as substrate transformation and produces viscous furoic acid

[0054] Add 10mM glucose in the M9 medium as the fermentation medium, convert mucofuroic acid with commercially available lignin at a concentration of 1, 2, and 5g / L during fermentation, and inoculate the R.opacus PD630-MA4 strain, such as Figure 4 As shown, the fermentation results showed that the maximum yield of mucofuroic acid was 0.023, 0.040, 0.078g / L respectively within 96h.

Embodiment 3

[0055] Example 3 Transform mucofuroic acid with the lignin of acid+alkali joint treatment as substrate

[0056] 1. The lignin treatment steps are: (1) 50g of corn stalks are added into 500mL of 1% sulfuric acid solution, treated with an autoclave at 120°C for 30min, and then the liquid is extracted with a vacuum filter pump; (2) ) Measure the dry weight of the remaining solids, add the dry matter to the total mass ratio of 1:10 into the NaOH solution with a mass fraction of 1%, and then use an autoclave to treat it at 120°C for 60min; (3) after collection and treatment The liquid was sterilized at 121°C for 15min and used as a substrate for engineering bacteria to ferment mucofuric acid; (4) by heating and concentrating at 60°C and using M9 medium, the lignin mother liquor was adjusted to a concentration of 500g / L, and this was used as a supplement The feed liquid is fermented to produce mucofuric acid from lignin.

[0057] 2. Using the pretreated lignin as the substrate for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com