Flexible flame-retardant coating with sensitive temperature sensing and fire early warning functions as well as preparation method and application of flexible flame-retardant coating

A fire warning and flame retardant coating technology, applied in the field of flame retardant coatings, can solve the problems that fire warning flame retardant coatings cannot realize repeatable temperature sensing and fire warning functions, low sensitivity of fire warning system, etc., and achieve sensitive real-time perception Ability, excellent heat insulation and oxygen insulation ability, good adhesion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] 1) Synthesis of thermoelectrically responsive layered nanomaterials: Add 0.1 g of graphene and 150 mL of acetone into a 250 mL four-neck flask, and fully disperse them through mechanical stirring and ultrasonic treatment for 30 min. 0.2 g of 3,4-ethylenedioxythiophene was added, and the reaction temperature was adjusted to 50°C. Dissolve 1 g of ferric chloride in 50 g of acetone by mechanical stirring for 15 min, add it dropwise to the reaction solution within 1 h, and keep stirring for 8 h after the drop is complete. After the reaction, the reaction solution was allowed to stand at room temperature and centrifuged, the precipitate was washed three times with acetone, and dried in an oven at 80° C. for 6 hours to obtain a thermoelectrically responsive layered nanomaterial.

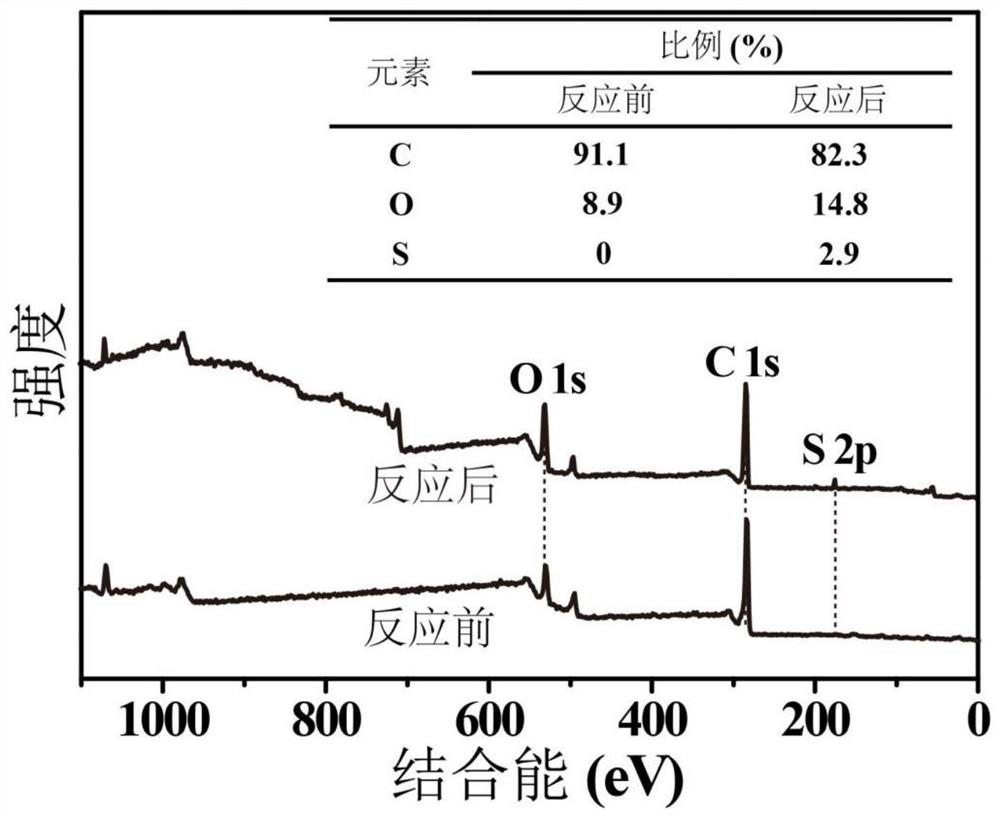

[0037] X-ray photoelectron spectroscopy (XPS) analysis was performed on the functionalized chain-like natural polymer. From figure 1 It can be observed that graphene is composed of 91.1% C and 8.9...

Embodiment 2

[0041] The difference between this example and example 1 is: in step 1), the amount of graphene is increased to 0.5g, acetone is replaced by n-hexane, and the mechanical stirring and ultrasonic treatment dispersion time is extended to 50min; 0.2g 3,4-ethylenedi Oxythiophene was replaced by 0.5g pyrrole, and the reaction temperature was increased to 70°C; 1g ferric chloride was replaced by 3g ammonium persulfate, the dropping time was shortened to 0.5h, and the reaction time was extended to 20h; the drying temperature of the product was reduced to 60°C, and the drying time Extended to 12h; in step 2), polyvinyl alcohol was replaced by hydropropyl methylcellulose, the amount of thermoelectric response layered nanomaterials was increased to 1g, and the time of mechanical stirring and ultrasonic treatment was extended to 30min. The coating amount of each spray on pine wood is reduced to 0.08mL / cm2, the drying temperature is reduced to 80°C, the drying time is extended to 20min, and...

Embodiment 3

[0043] The difference between this embodiment and Example 1 is: in step 1), 0.1g graphene is replaced by 0.05g montmorillonite, acetone is replaced by ethanol, and the mechanical stirring and ultrasonic treatment dispersion time is extended to 360min; 3,4-ethylene The amount of dioxythiophene is increased to 0.5g, and the reaction temperature is increased to 70°C; 1g of ferric chloride is replaced by 2g of ferric nitrate, the dropping time is extended to 2h, and the reaction time is extended to 24h; the drying temperature of the product is reduced to 40°C, and the drying time Extended to 24h; 0.5g polyvinyl alcohol in step 2) was replaced by 0.4g carboxymethyl cellulose, the amount of thermoelectric response layered nanomaterials was increased to 1.6g, and the time of mechanical stirring and ultrasonic treatment was extended to 30min. and Pinus sylvestris wood the coating volume per spray is reduced to 0.02mL / cm 2 , the drying temperature is reduced to 60°C, the drying time is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com