Inorganic salt additive for surface roughening treatment of low-profile electrolytic copper foil and its treatment process

A technology of surface treatment and roughening treatment, which is applied in the field of inorganic salt additives for surface roughening treatment of low-profile electrolytic copper foil and its treatment process, which can solve the difficulty of real-time monitoring of additive content, uncontrollable organic additive content, production Efficiency and economic benefits and other issues, to achieve the effect of isolating the outside, improving anti-oxidation and anti-stripping ability, and easy to operate and implement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0033] According to a preferred embodiment of the present invention, the coated fluid contains 5-200 mg / L sodium hexluorolsid silicate, 5-100 mg / L sodium thioate, 25-75 g / L of copper sulfate and 80- 140 g / l concentrated sulfuric acid.

[0034] The second aspect of the present invention provides a method of surface treatment of a copper foil comprising: a copper foil sequentially performs roughening, curing treatment, passivation processing, coating treatment, and drying treatment;

[0035]Wherein, the roughening is roughened to roughen the copper foil from the first aspect.

[0036] In the present invention, it has a wide choice of the foil, preferably a copper foil with a thickness of 12-70μm. In the present invention, there is no special note, the standard copper foil thickness is 12-70μm.

[0037] In the present invention, has a wide range of options of the roughening treatment conditions, preferably, the roughening treatment of conditions comprising: a temperature of 1...

Embodiment 1

[0067] (1) Pickling process: sulfuric acid is diluted to a concentration of 10vol% dilute sulfuric acid was pumped into the pickling tank, the immersion pickling tank 35μm copper foil was placed, through deionized water after immersion of the copper foil surface. cleaning, conveying roller gear speed is 20m / min, the treatment liquid circulation rate of each slot is 15L / min;

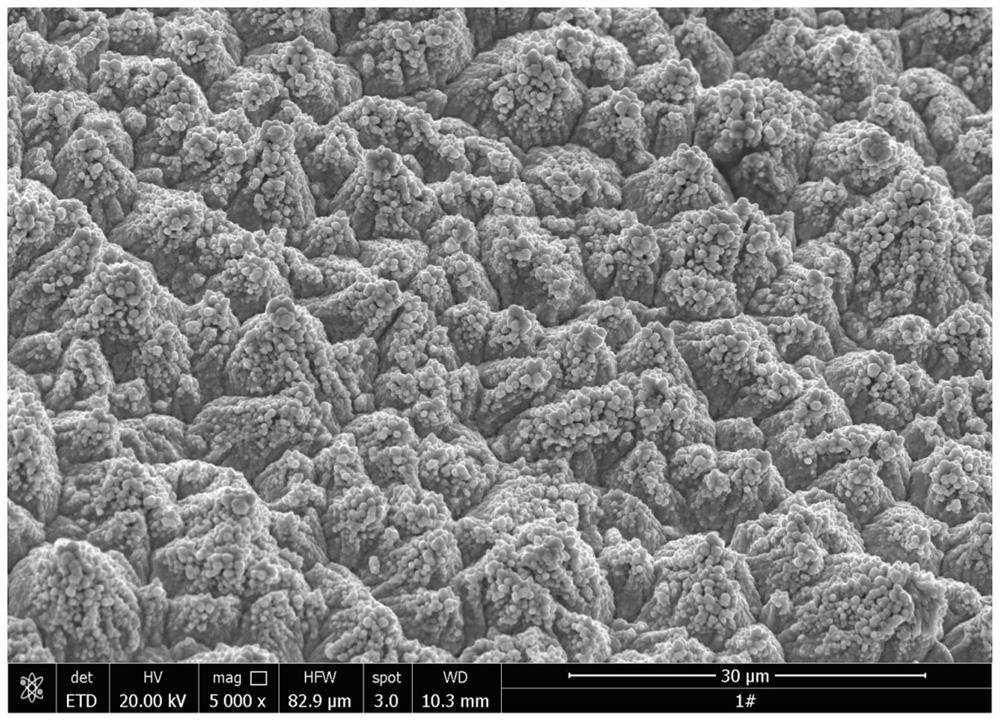

[0068] (2) roughening treatment: After cleaning the foil into the tank filled with roughened roughened roughened solution, wherein the concentration of copper sulfate roughening solution was 40g / L, the concentration of concentrated sulfuric acid 100g / L, sodium hexafluorosilicate concentration of 120mg / L and concentration of sodium tungstate thio 50mg / L, the conditions for roughening treatment comprises: a temperature of 25 ℃, a current density of 35A / dm 2 , Time is 4s;

[0069] (3) curing: the roughened copper foil treated after washing with deionized water, into the liquid filled with cured cur...

Embodiment 2

[0076] (1) Pickling process: sulfuric acid is diluted to a concentration of 10vol% dilute sulfuric acid was pumped into the pickling tank, the immersion pickling tank 35μm copper foil was placed, through deionized water after immersion of the copper foil surface. cleaning, conveying roller gear speed is 15m / min, the treatment liquid circulation rate of each slot is 20L / min;

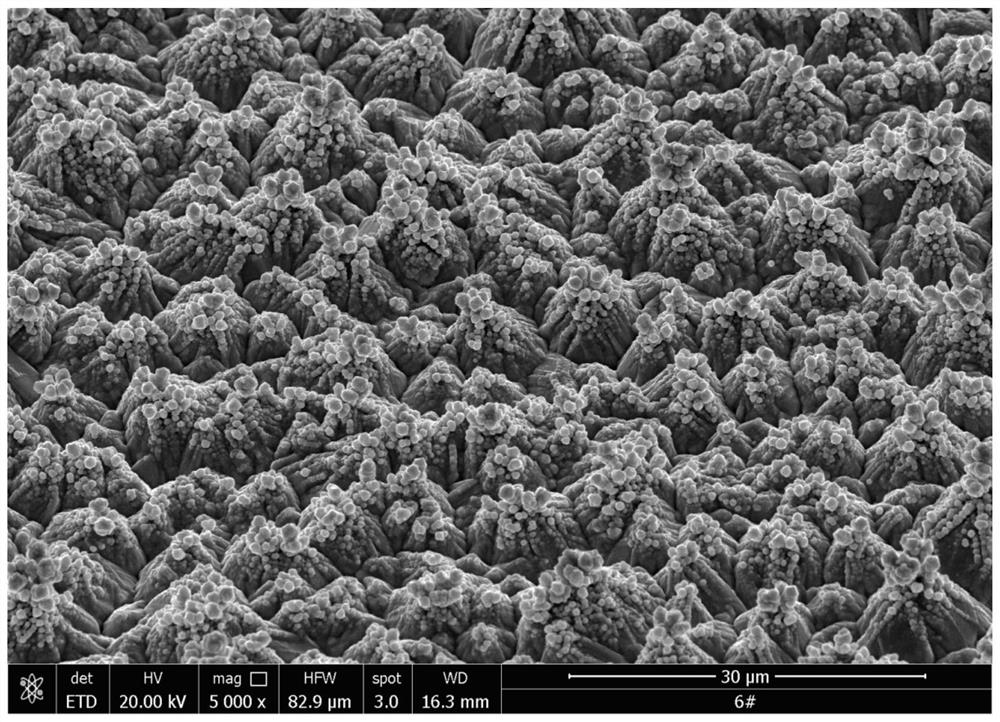

[0077](2) roughening treatment: After cleaning the foil into the tank filled with roughened roughened roughened liquid, wherein the copper sulfate concentration in roughening was 60g / L, sulfuric acid concentration of 120g / L, the concentration of sodium hexafluorosilicate was 120mg / L and a concentration of sodium thiosulfate tungsten 50mg / L, the conditions for roughening treatment comprises: a temperature of 20 ℃, a current density of 40A / dm 2 , Time is 15s;

[0078] (3) curing: the roughened copper foil treated after washing with deionized water, into the liquid filled with cured cured cured tan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com