Mesoporous quercetin zirconium catalyst and application thereof in preparation of alpha, beta-unsaturated alcohol

A technology of quercetin and catalyst, which is applied in the field of chemical synthesis, can solve the problems of unsafe storage and transportation of hydrogen, high requirements for production equipment, and low selectivity, and achieve the effects of convenient operation, easy preparation, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] The preparation of embodiment 1 mesoporous quercetin zirconium catalyst

[0049] Proceed as follows:

[0050] Weigh ZrCl with a molar ratio of 1.5 / 1 4 Add quercetin and quercetin into the reaction kettle lined with polytetrafluoroethylene; ② Add DMF to dissolve and stir magnetically at room temperature for one hour; ③ After the solid matter is completely dissolved, seal the stainless steel autoclave, and then Raise the temperature to 120°C, stop heating after 12 hours of reaction, and cool naturally to room temperature; ④ Suction filter the cooled substance, wash with DMF, acetone and ethanol for 2 to 5 times, and vacuum dry at 60°C to obtain mesoporous Quercetin zirconium catalyst (abbreviation: Que-Zr(1 / 1.5)).

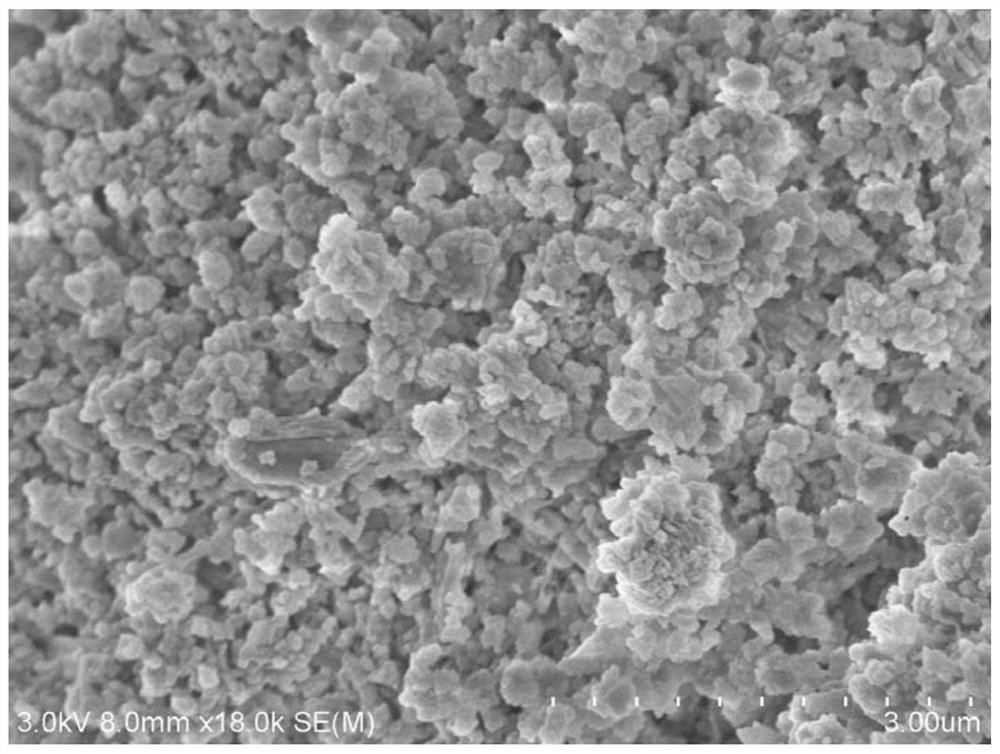

[0051] figure 1 It is the scanning electron microscope spectrum of Que-Zr(1 / 1.5) catalyst obtained in this embodiment.

[0052] In addition, Que-Zr(1 / 0.5), Que-Zr(1 / 1), Que-Zr(1 / 2), Que-Zr(1 / 3) catalyst materials are also synthesized by a similar method, the...

Embodiment 2

[0054] The quercetin zirconium catalyst Que-Zr (1 / 1.5) that the embodiment 1 of 0.15g is made joins in the liner of clean autoclave, then adds 1mmol cinnamaldehyde, 5mL isopropanol and the magneton of suitable size After the stainless steel high-pressure reactor is packaged, react at 100°C for 4 hours under the action of magnetic stirring. After the reaction is completed and cooled, the supernatant is detected and analyzed by a gas chromatograph. Naphthalene is used as an internal standard to calibrate the concentration of the liquid product and calculate the yield. .

Embodiment 3

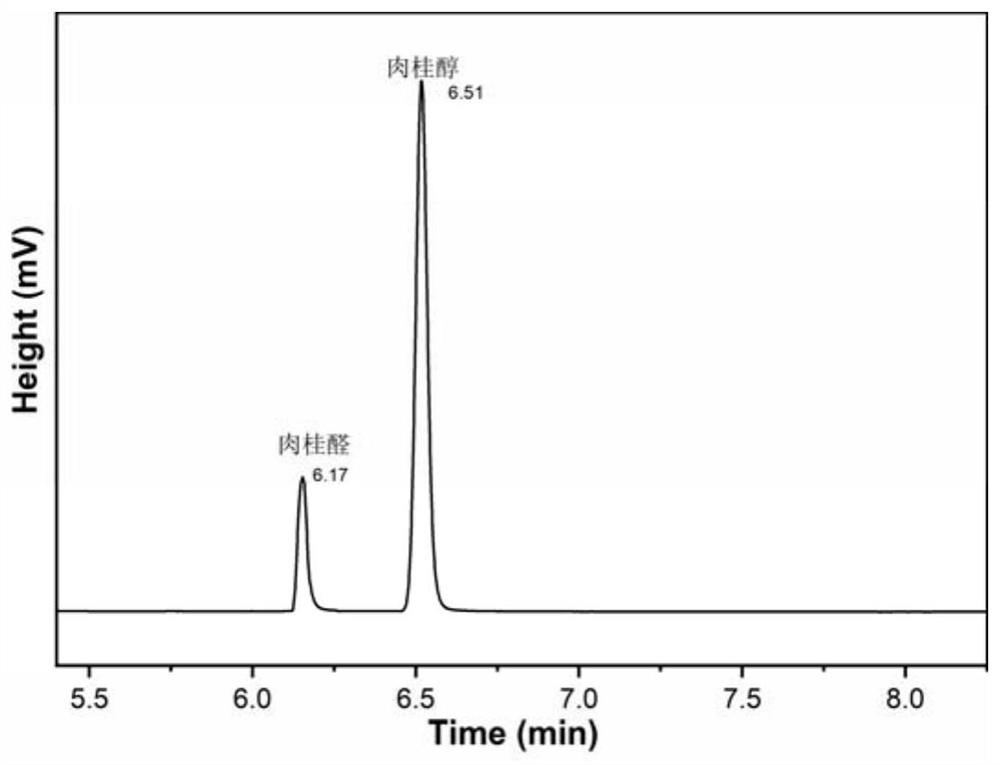

[0056] This embodiment compares the influence of different catalysts on the preparation of cinnamyl alcohol.

[0057] Add 0.1 g of quercetin zirconium catalysts (Que-Zr(1 / 0.5), Que-Zr(1 / 1), Que-Zr(1 / 2), Que-Zr(1 / 3)) in different molar ratios Add 1mmol cinnamaldehyde, 5mL isopropanol and magnets of appropriate size to the inner lining of a clean autoclave. After sealing the stainless steel autoclave, react at 100°C for 3 hours under magnetic stirring. After the reaction is completed, wait for cooling Take the supernatant for detection and analysis, see the specific gas chromatography results figure 2 .

[0058] The results of the corresponding catalytic process are shown in Table 1. From Table 1, it can be seen that when using Que-Zr (1 / 1.5) as a catalyst, under the same conditions, the yield and selectivity of cinnamyl alcohol are the best.

[0059] Table 1 Catalytic reaction results under different quercetin content obtained zirconium catalysts

[0060] catalyst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com