Preparation method of short-oil alkyd resin anticorrosive enamel paint with high corrosion potential

A technology of alkyd resin and corrosion potential, applied in the field of enamel paint, can solve the problems of failing to meet anti-corrosion requirements and complicated preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] 1. Material handling

[0019] The material was polished with 1.0 μm and 0.3 μm alumina powder on a polishing cloth in turn, then placed in 5% hydrochloric acid for 5 min, then placed in deionized water for ultrasonic cleaning for 3 times, each time for 5 min, and finally placed in an Sonicated in water and ethanol for 6 min and then dried for later use.

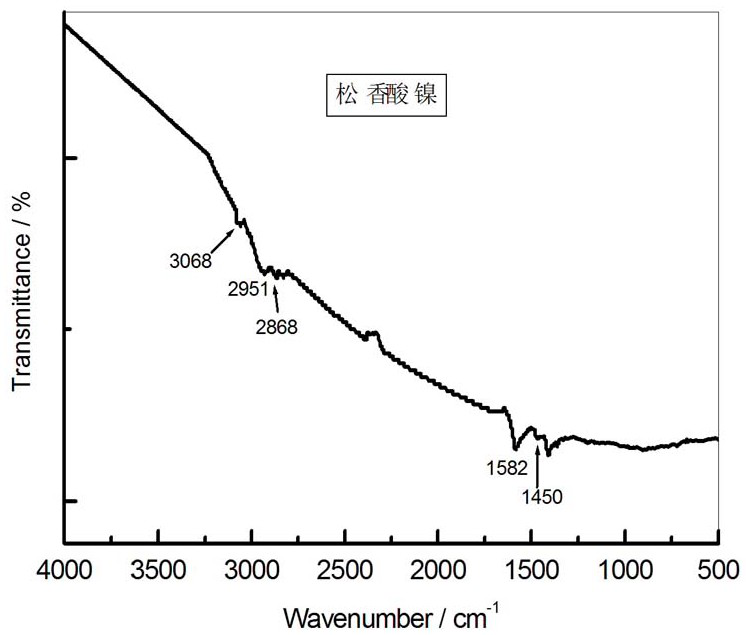

[0020] 2. Preparation of nickel anti-corrosion enamel with and without rosin acid

[0021] Add 1 mole of abietic acid and 1 mole of nickel acetylacetonate into a round bottom flask, add an appropriate amount of solvent benzyl alcohol, heat and reflux at 200 degrees Celsius for 45 minutes, then transfer it to a pulverizer while it is hot, and pulverize after cooling 2 minutes, then use a volume ratio of 60% ethanol aqueous solution to wash the product, and dry it for 1 hour at a temperature of 80 degrees Celsius to obtain nickel abietate;

[0022] Add 45 parts by weight of dry short oil alkyd resin and 2.0 parts by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com