A kind of bacillus licheniformis and use thereof

A technology of bacillus licheniformis and edible alkali, which is applied in the fields of fermentation engineering and enzyme engineering, can solve the problems of high product prices, harsh requirements, and high production costs, and achieve the effects of facilitating promotion, improving adsorption capacity, and reducing equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1 This embodiment relates to an enlarged culture of Bacillus underclothes

[0034] First, strains expand the culture

[0035] 1. Save the strains: Save the tube slope.

[0036] 2, beveled seed culture

[0037] 1) Preparation of beveled medium: Dipassass of starch, corn, and magnesium hydrogen phosphate, magnesium sulfate, control starch, corn pulp, hydrogen phosphate, and magnesium sulfate, the mass fraction of magnesium sulfate is: 1%, 2%, respectively. 0.1%, 0.02%, with a hydroxide adjusted to be about 7, and the agar, 121 ° C, 30 min sterilized according to the weight of the solution. Another solution of sodium carbonate is 20% aqueous solution, which is equipped with 121 ° C, 30 minutes. After sterilization, the amount of sodium carbonate is mixed with other medium components after the end of the concentration of 1%, and the sodium carbonate is mixed with other medium components. Put into the sterile test tube, becomes a slope. After the inclined is solidifie...

Embodiment 2

[0048] EXAMPLES 2 This embodiment relates to a method of preparing a solid seed curve, and includes the steps of:

[0049] 1. Cultivation of Solid Seeds:

[0050] 1) The medium component:

[0051] A. Nutrient formulation: 2% sodium carbonate, 2 potassium hydrogen phosphate (chemical fertilizer), magnesium sulfate (chemical pure) 0.02%, prepared with tap water. Stir dissolve.

[0052] B. Solid seed curvature ingredients: peanut shell rolled down, add nutrient solution in 1: 1.2 ratio. Mix even in the stainless steel basin. 121 ° C, 30 minutes sterilization. That is, a solid seed curvature medium.

[0053] 2) Seedcam inoculation: Sterilized spectrum culture medium, in the seed culture chamber, the temperature of the material is cooled to 37-40 ° C in a 10 kg peanut shell, inoculated with 1 to 3 eggplant flasks, inoculated. Each eggplant bottle plus 50 ml of sterile water, scraped bacterial cells with a sterile squeezed knife, and completely dissipation. A small amount of material is...

Embodiment 3

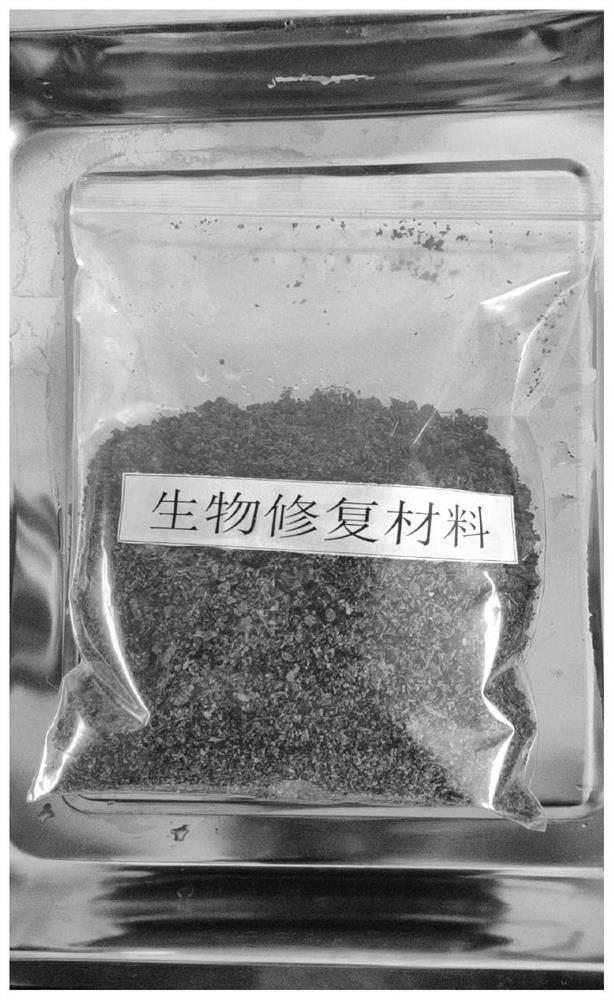

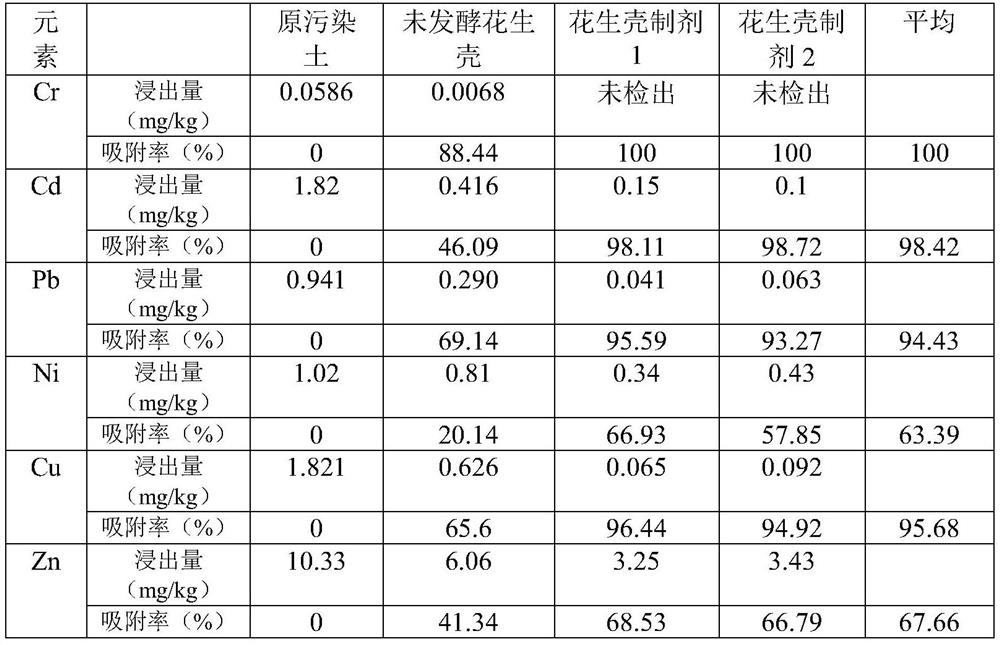

[0056] Example 3 This example embodiment is directed to a fermentation peanut shells, peanut shells formulations prepared

[0057] 1, fermentation ingredients: Weigh crushed peanut shells 100kg.

[0058] Another sodium weighed 2.4kg, dipotassium phosphate 120g, magnesium sulfate 24g, add water 120kg. Stirred to dissolve. Add peanut shell, turned mixed uniformly. You can be vaccinated.

[0059] 2, inoculated fermentation materials: culture material with a good, solid seed song weighed 10kg, the dispersion material added in turn mixed uniformly.

[0060] 3, peanut shells fermentation

[0061] After inoculation of the fermentation material, before stacking, a thermometer plug, floating blanket plastic film, heat, moisture culture fermentation until the material temperature rises to 35-40 deg.] C, clawed paving, 10-20cm controlling material thickness, floating plastic blanket film, culture was continued. During the culture, the culture temperature in accordance with needs, a gap turne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com