Nano bismuth/nitrogen-doped carbon foam nanosheet two-dimensional composite material as well as preparation method and application thereof

A nitrogen-doped carbon, composite material technology, applied in nanocarbon, nanotechnology, nanotechnology and other directions, can solve the problems of uneven graphene coating, solid-state electrolyte interface rupture, reduced Coulomb efficiency, etc., and achieve excellent cycle stability , the effect of excellent electronic conductivity and safe preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

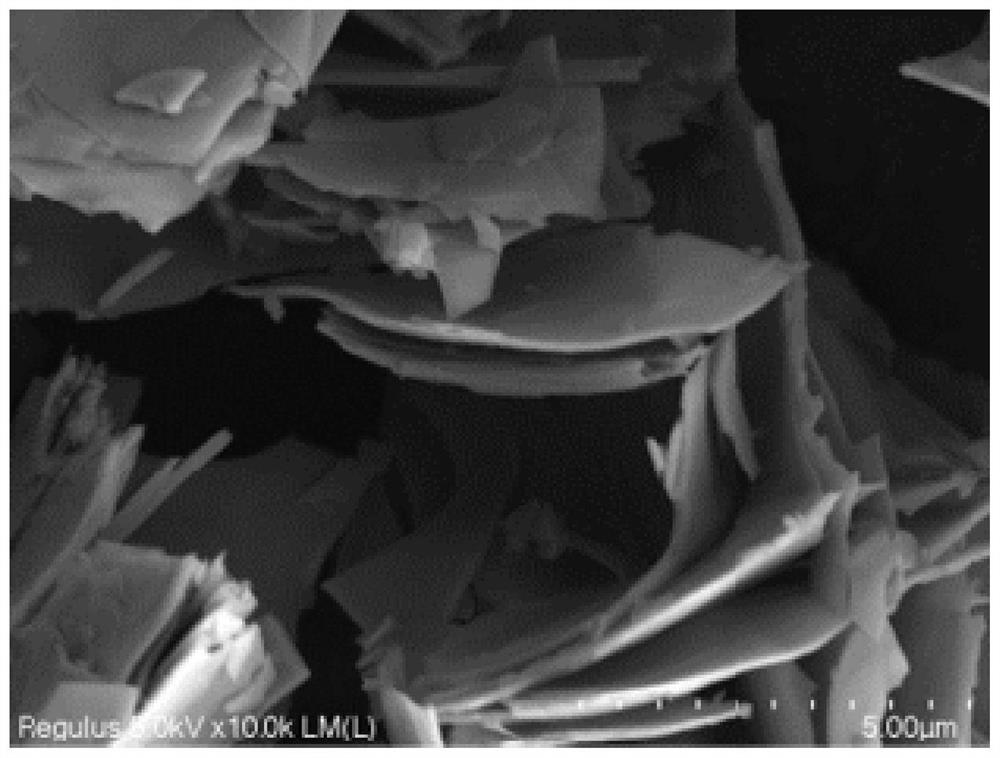

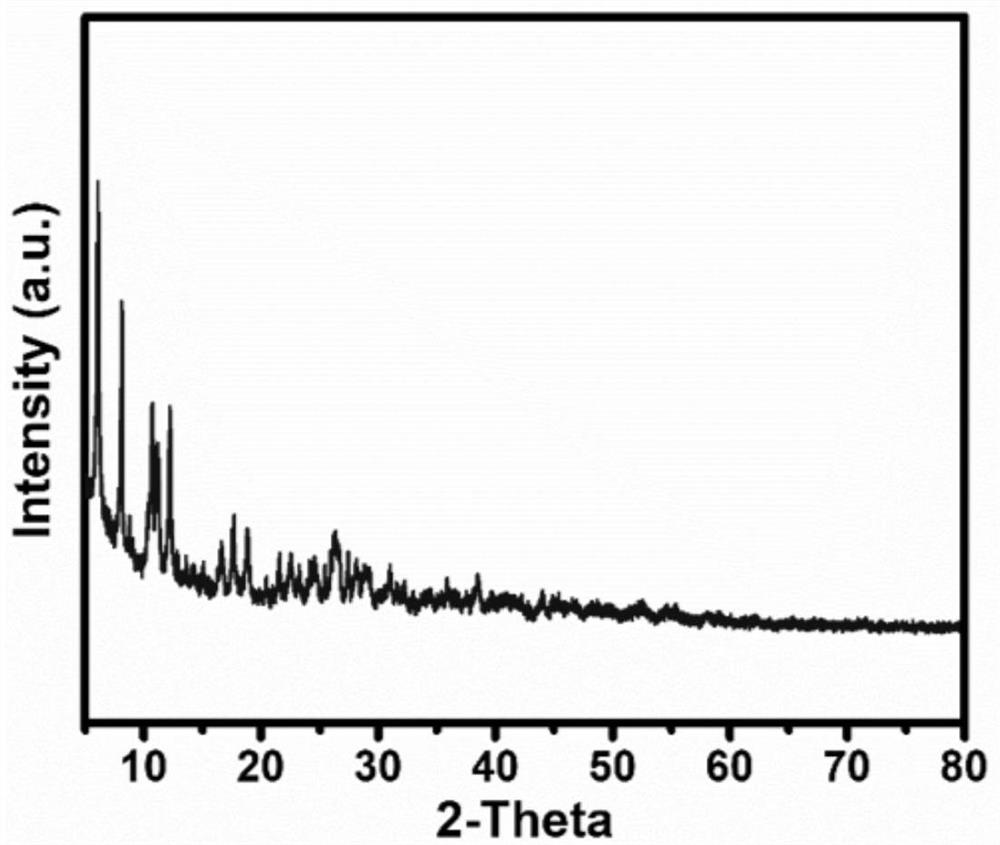

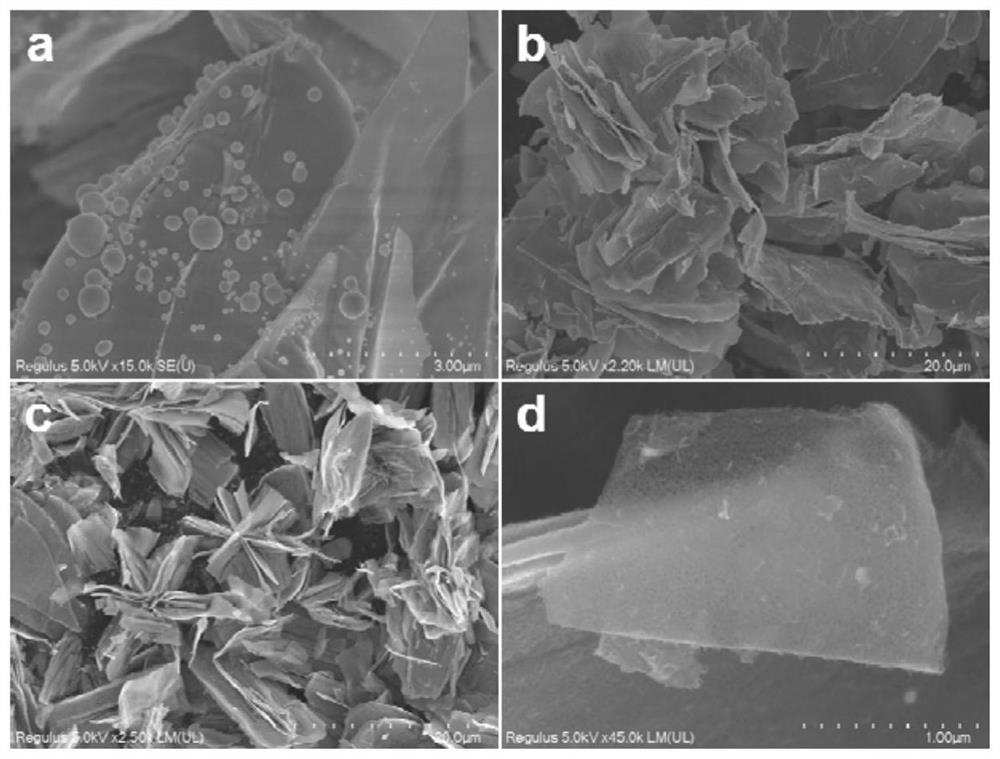

Embodiment 1

[0045] Take 20 mL of ethylene glycol in the lining of a 50 mL reaction kettle, add 0.05 g of bismuth nitrate pentahydrate, stir with a magnetic stirrer until the bismuth source is completely dissolved in ultrapure water, add 0.25 g of trimesic acid after stirring and dissolving, Stirring was continued for 0.5h to obtain A solution. Put the solution A in a hydrothermal kettle and transfer it to an oven to raise the temperature to 120° C. and keep it warm for 6 hours. After natural cooling, the mixed solution containing the precursor, that is, the bismuth-based metal-organic framework compound, was vacuum filtered and washed with ethylene glycol to obtain a paste precursor; the paste precursor was dried at 70°C , the drying time was 10 hours, and the precursor of the white powder was obtained; 0.05g of the dried bismuth-based metal-organic framework compound precursor was placed in a porcelain boat, and 0.5g of melamine was placed in the upstream of the tube furnace air flow, re...

Embodiment 2

[0047] Take 20 mL of ethylene glycol in the lining of a 50 mL reaction kettle, add 0.03 g of bismuth trichloride, stir with a magnetic stirrer until the bismuth source is completely dissolved in ultrapure water, add 0.2 g of trimesic acid after stirring and dissolving, Stirring was continued for 0.5h to obtain A solution. Put the solution A in a hydrothermal kettle and transfer it to an oven to raise the temperature to 120° C. and keep it warm for 6 hours. After natural cooling, the mixed solution containing the precursor, that is, the bismuth-based metal-organic framework compound, was centrifuged and washed 4 times with methanol to obtain a paste precursor; the paste precursor was dried at 50 ° C. The drying time was 12 hours, and the precursor of white powder was obtained; 0.05 g of the dried bismuth-based metal organic framework compound precursor was placed in a porcelain boat, and 0.25 g of melamine was placed in the upstream of the tube furnace air flow, respectively, a...

Embodiment 3

[0049] Take 20 mL of ethylene glycol in the lining of a 50 mL reaction kettle, add 0.05 g of bismuth nitrate pentahydrate, stir with a magnetic stirrer until the bismuth source is completely dissolved in ultrapure water, add 0.3 g of trimesic acid after stirring and dissolving, Stirring was continued for 0.5h to obtain A solution. Put the solution A in a hydrothermal kettle and transfer it to an oven to raise the temperature to 120° C. and keep it warm for 6 hours. After natural cooling, the mixed solution containing the precursor, that is, the bismuth-based metal-organic framework compound, was vacuum filtered and washed with ethylene glycol to obtain a paste precursor; the paste precursor was dried at 80°C , the drying time was 24 hours, and the precursor of white powder was obtained; the bismuth-based metal-organic framework compound precursor after 0.05g drying was placed in a porcelain boat, and 0.3g melamine was placed in the upstream of the tube furnace air flow, at 100...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com