Size-controllable aerogel ball as well as preparation method and application thereof

An airgel ball and aerogel technology are applied in the fields of airgel preparation, chemical instruments and methods, and colloid chemistry. The effect of high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

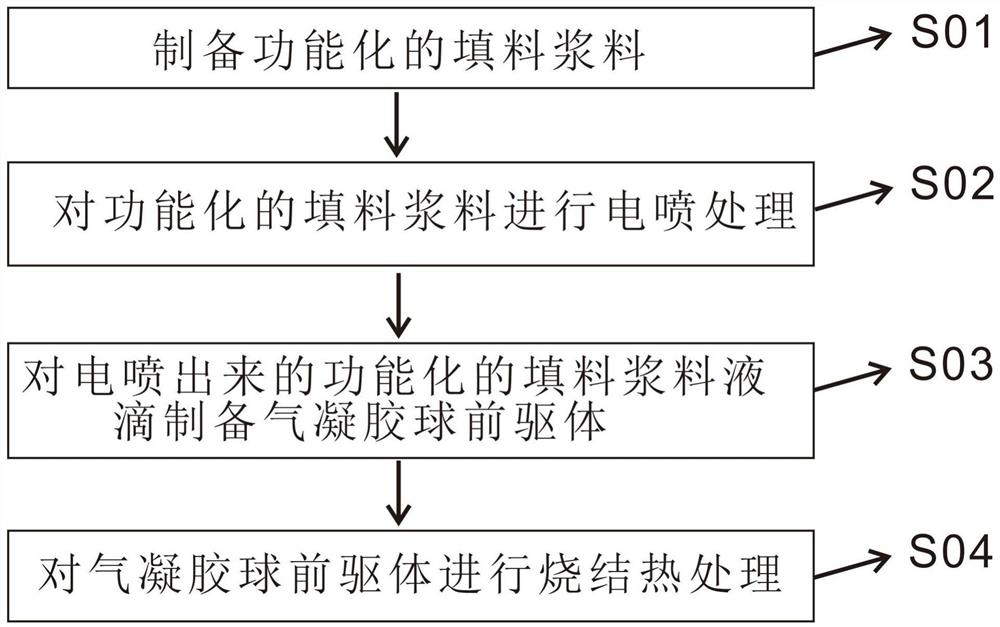

[0038] The invention provides a general method for preparing size-controllable airgel spheres. The general process steps of the method for preparing size-controllable airgel spheres of the present invention are as follows: figure 1 As shown, it includes the following steps:

[0039]S01. Prepare functionalized filler slurry: mix filler, viscosity modifier, salt and water according to mass ratio 1: (0.05-0.2): (0.025-0.05): (5-50) to obtain functionalized filler slurry;

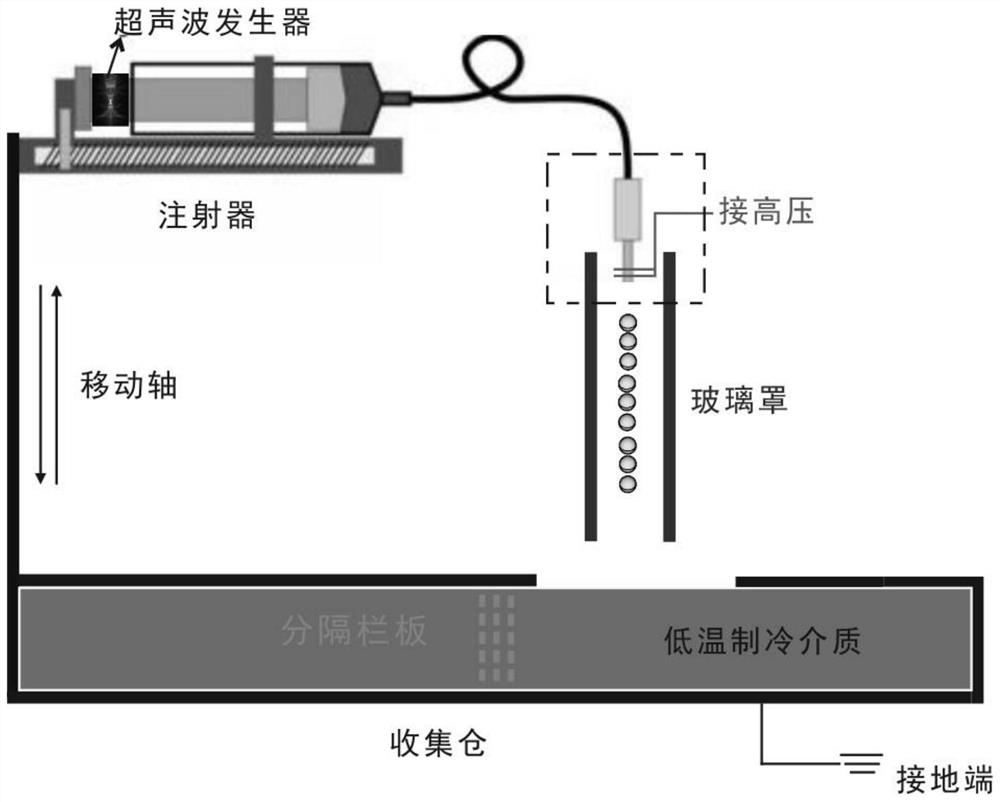

[0040] S02. EFI processing the functionalized filler slurry: put the functionalized filler slurry into the EFI treatment device to obtain filler slurry droplets with controllable diameter;

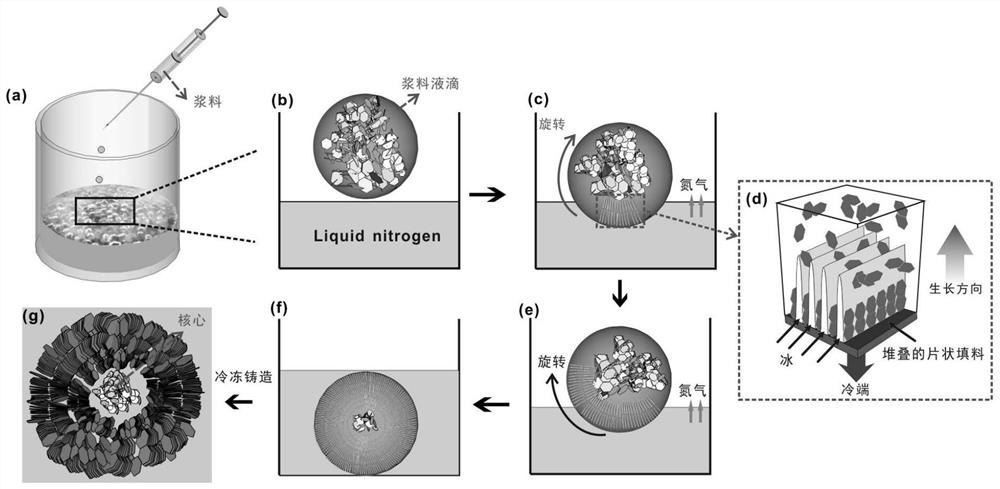

[0041] S03. Prepare an airgel ball precursor from the functionalized filler slurry droplets produced by electrospray: drop the filler slurry droplets with controllable diameter into a low-temperature refrigeration medium, perform freezing treatment to form a frozen mixture, and The frozen mixture is subjected to freeze-d...

Embodiment 1

[0050] The preparation method of the boron nitride microsheet airgel ball provided by embodiment 1 refers to the attached figure 1 shown, including the following specific steps:

[0051] S11: Mix boron nitride microflakes with a size of 500nm, sodium carboxymethyl cellulose, sodium chloride, and water at a mass ratio of 1:0.2:0.05:10, and stir in a planetary mixer for 4 hours at a stirring speed of 70rpm to obtain Functionalized boron nitride microsheet slurry;

[0052] S12: Put the functionalized boron nitride microsheet slurry into the electrospray treatment device, the distance between the boron nitride microsheet slurry injection end and the collection device is 20 cm, and the distance between the filler slurry injection end and the collection device The voltage difference is 20kV, the propulsion rate of the automatic propulsion device is 1cm / min, and the diameter of the boron nitride microsheet slurry droplet is 180μm;

[0053] S13: drop the boron nitride microsheet slu...

Embodiment 2

[0057] The preparation method of the silicon carbide nanowire airgel sphere provided by embodiment 2 refers to the attached figure 1 shown, including the following specific steps:

[0058] S21: Mix silicon carbide nanowires with a diameter of 200 nm and a length of 10 μm, hydroxypropyl methylcellulose, potassium chloride, and water at a mass ratio of 1:0.05:0.05:20, and then stir in a planetary mixer for 3 hours at a stirring speed of Be 60rpm, obtain functionalized silicon carbide nanowire slurry;

[0059] S22: Put the functionalized silicon carbide nanowire slurry into the electrospray treatment device, the distance between the silicon carbide nanowire slurry injection end and the collection device is 10 cm, and the voltage difference between the filler slurry injection end and the collection device 22kV, the propulsion rate of the automatic propulsion device is 3cm / min, and the diameter of the silicon carbide nanowire slurry droplet is 100μm;

[0060] S23: Drop the silico...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com