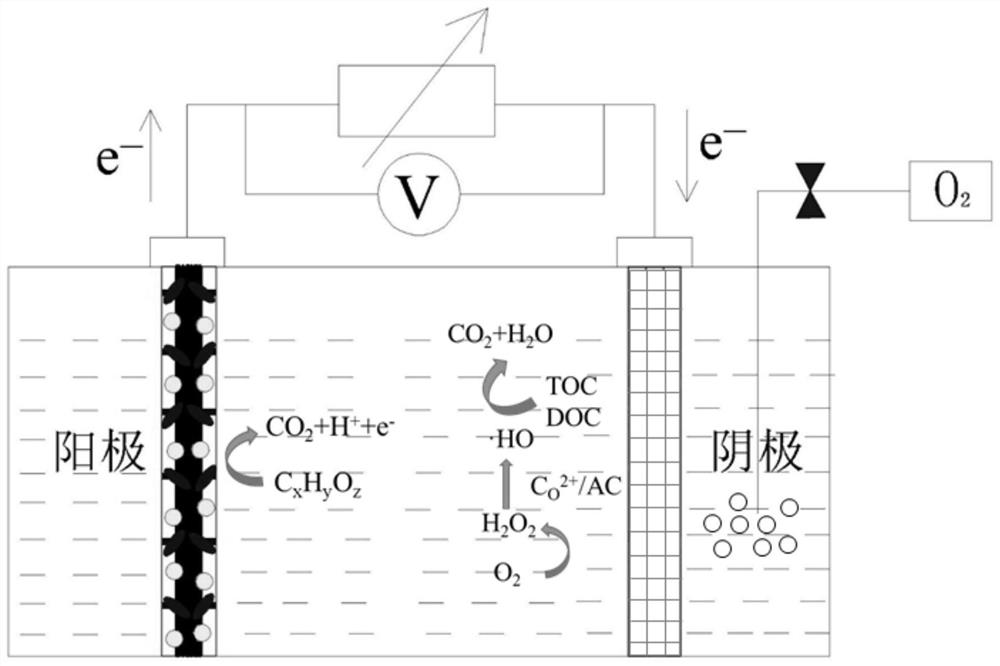

Single-chamber microbial electro-Fenton system and application thereof

A microbial electricity, Fenton technology, applied in biological water/sewage treatment, electrochemical biological combined treatment, water pollutants and other directions, can solve the problems of power consumption, narrow pH application range, fast catalyst consumption, etc., to reduce internal resistance , the structure is simple, the effect of high current density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] Embodiment 1: the preparation of single-chamber microbial electric Fenton system

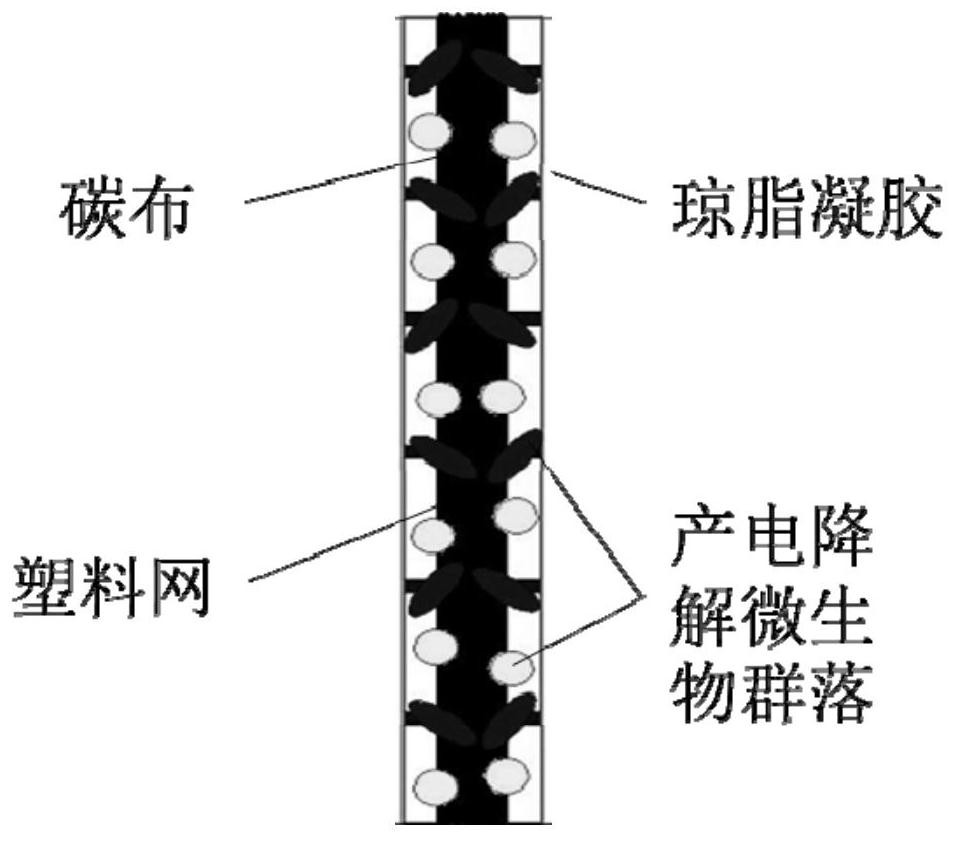

[0065] (1) Prepare the anode:

[0066] a. Preparation of anode base material: set the surface density to 125g / m 2 , a carbon cloth with a thickness of 360μm and a size of 4cm×3cm is rolled into a cylindrical shape after being treated at a high temperature in a muffle furnace at 430°C for 30 minutes; the thickness of the carbon cloth layers is 0.1mm, and the size is 1mm× A 3mm plastic mesh is used as a separator to ensure the attachment and growth of mixed bacteria between the carbon cloth layers. The rolled carbon cloth was soaked in acetone for 24 hours to remove the oily substance to obtain the anode substrate.

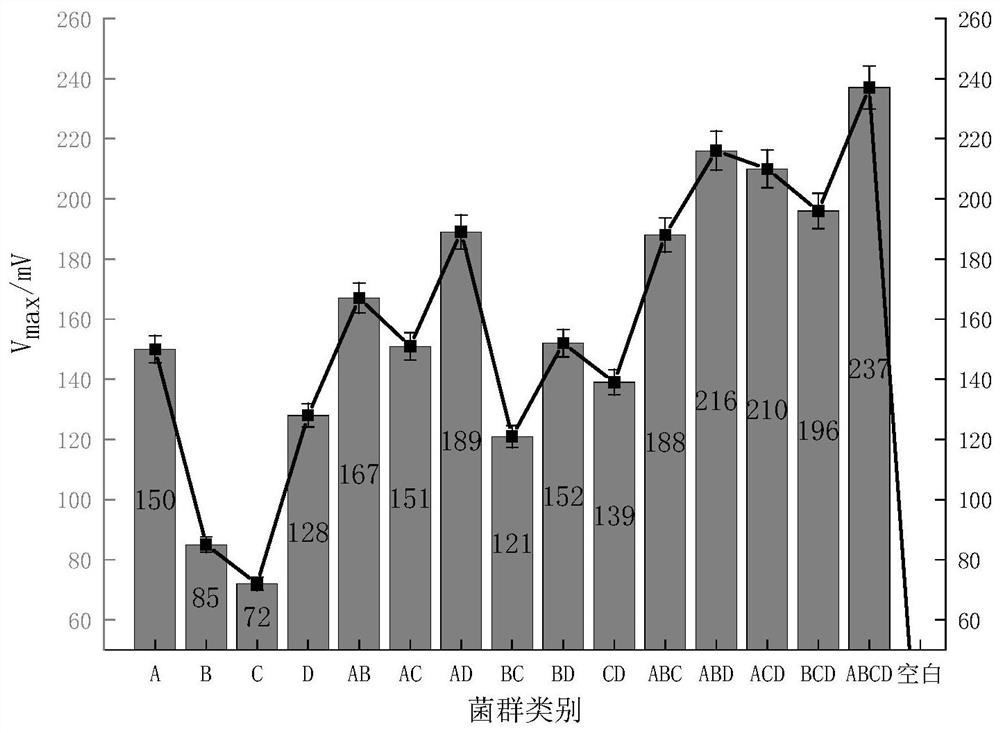

[0067] b. Cultivation of mixed bacteria: with the inoculum size of 4:1:1:3, the OD 600 =0.8-1.0 of Rhodopseudomonas palustris, Proteus vulgaris, Bacillus toyonensis and Pacific phalanophore were inoculated in a sterile test tube filled with culture solution to obtain a bacte...

Embodiment 2

[0079] Embodiment 2: the method for single-chamber microbial electric Fenton system processing ship bilge water

[0080] (1) Acclimatization of mixed bacteria: Add sodium acetate to the single-chamber microbial electro-Fenton system to a final concentration of 10 mM. Adjust the resistance value of the variable resistor to 1000Ω, close the circuit to start the microbial electro-Fenton system, and when the system can still output a stable current after more than 3 cycles, the domestication of the mixed bacteria is completed.

[0081] (2) Treatment of bilge water: When the output voltage of the anode mixed bacteria is greater than 20mV, adjust the variable resistor to 10Ω, and then add bilge water twice the volume of the culture solution to the single-chamber microbial electro-Fenton system, Carry out degradation and purification treatment of bilge water.

Embodiment 3

[0082] Embodiment 3: Application of single-chamber microbial electric Fenton system in ship bilge water treatment

[0083] Figure 5 It is a schematic flow chart of the treatment of bilge water by the single-chamber microbial electro-Fenton system of the present invention. Such as Figure 5 As shown, the bilge water is preliminarily treated by sedimentation in the sedimentation tank, and the sludge and impurity particles are filtered out, and then discharged into the collection tank by the water pump for treatment. After the microbial electro-Fenton system generates a stable voltage, the bilge water is pumped into the microbial electro-Fenton system to adsorb and degrade TOC and COD in the bilge water to achieve the purpose of purifying the bilge water. If the treated bilge water meets the discharge requirements, it will be sent to the storage tank for water use in ship toilets or for diluting bilge water with high concentration; if it does not meet the standard, it will flo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com