Low-temperature combustion-supporting environment-friendly additive for natural gas and preparation method thereof

A natural gas and environmental protection technology, applied in the direction of gas fuel, fuel additives, fuel, etc., can solve the problems of natural gas burning, natural gas opening, difficult methane activation and catalytic treatment, etc., to improve the activity performance, improve the activity, and optimize the preparation scheme Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

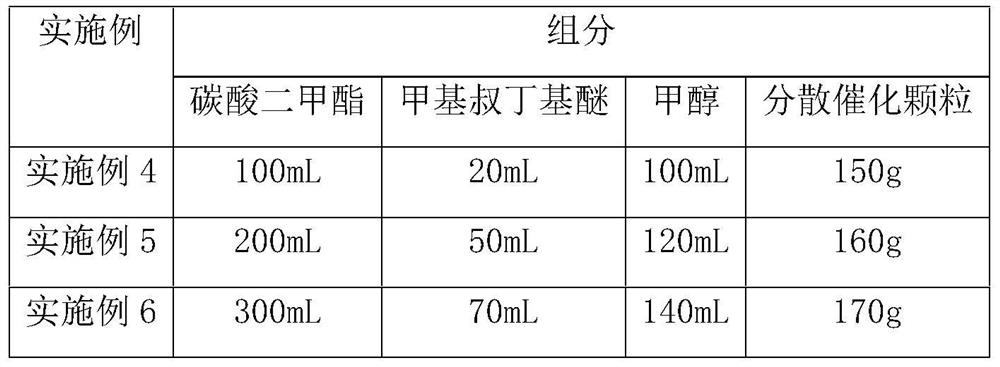

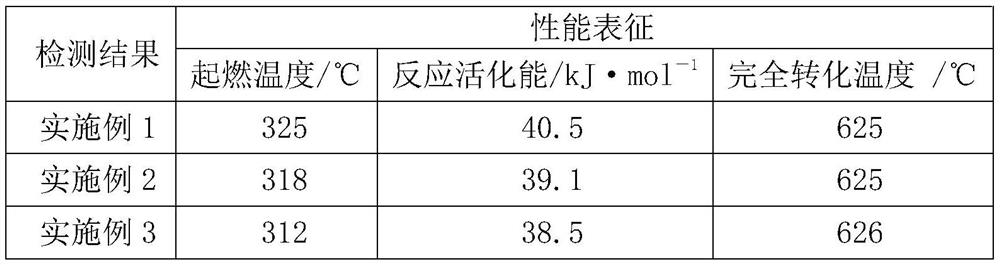

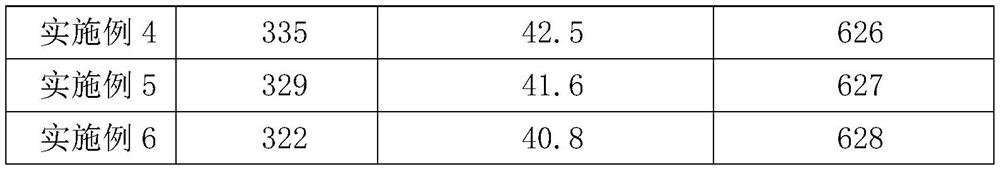

Examples

Embodiment 1

[0030] According to the mass ratio of 1:3:10, mix resorcinol, sodium carbonate and deionized water and place it under magnetic stirring at room temperature for 25 minutes to obtain a mixed solution, and according to the volume ratio of 1:8, drop the mass fraction of 5% formaldehyde solution Add it to the mixed solution, stir and mix, place in an oven at 45°C, and age for 6 hours to obtain an aged sol; use ethanol to replace the solvent of the aged sol, and then dry it at 45°C for 6 hours to obtain a dry gel Gel, take the dried gel and place it in a tube-type atmosphere furnace, heat up to 850°C at a rate of 5°C / min, heat-preserve it under an argon atmosphere for 45min, and let it stand to cool to room temperature to obtain a carbon airgel matrix;

[0031] According to the mass ratio of 1:12, the silane coupling agent and the carbon airgel matrix were stirred and mixed and ground at room temperature, the abrasive particles were collected and kept at 55°C for 6 hours, and the dri...

Embodiment 2

[0035] According to the mass ratio of 1:3:10, resorcinol, sodium carbonate and deionized water were mixed and placed at room temperature for 27 minutes with magnetic stirring to obtain a mixed solution, and according to the volume ratio of 1:8, the mass fraction of 5% formaldehyde solution was dropped Add it to the mixed solution, stir and mix, place in an oven at 47°C, and age for 7 hours to obtain an aged sol; use ethanol to replace the solvent of the aged sol, and then dry it at 50°C for 7 hours to obtain a dry gel Gel, take the dried gel and place it in a tube-type atmosphere furnace, heat up to 875°C at a rate of 5°C / min, heat-preserve it under an argon atmosphere for 52min, and let it stand to cool to room temperature to obtain a carbon airgel matrix;

[0036] According to the mass ratio of 1:12, the silane coupling agent and the carbon airgel matrix were stirred and mixed and ground at room temperature. The abrasive particles were collected and kept at 57°C for 7 hours. ...

Embodiment 3

[0040] According to the mass ratio of 1:3:10, mix resorcinol, sodium carbonate and deionized water and place it under magnetic stirring at room temperature for 30 minutes to obtain a mixed solution, and according to the volume ratio of 1:8, drop the mass fraction of 5% formaldehyde solution Add it to the mixed solution, stir and mix it and place it in an oven at 50°C, and age it for 8 hours to obtain an aged sol; use ethanol to replace the solvent of the aged sol, and then dry it at 55°C for 8 hours to obtain a dry gel Gel, take the dried gel and place it in a tube-type atmosphere furnace, heat up to 900°C at a rate of 5°C / min, heat-preserve it under an argon atmosphere for 60 minutes, and let it stand to cool to room temperature to obtain a carbon airgel matrix;

[0041] According to the mass ratio of 1:12, the silane coupling agent and the carbon airgel matrix were stirred and mixed and ground at room temperature. The abrasive particles were collected and kept at 60°C for 8 h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com