Glucoside hydrolase CmChi3 and application thereof in degradation of hydrolyzed colloid chitin

A technology of glycoside hydrolase and hydrocolloid, which is applied in the field of glycoside hydrolase CmChi3 and its application in degrading hydrocolloid chitin, which can solve the problems of easy-to-contaminate bacteria, low cost conversion rate, and industrial production that has not yet been realized.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0091] Source of bacteria

[0092] Bacterial strains used in the present invention Chitinolyticbacter meiyuanensis SYBC-H1 was screened by our laboratory and preserved in China General Microorganism Collection (CGMCC 3438) and American Type Microorganism Collection (ATCC BAA-2140).

Embodiment 2

[0094] Chitinase cm The construction of the Chi3 recombinant strain, the specific steps are as follows:

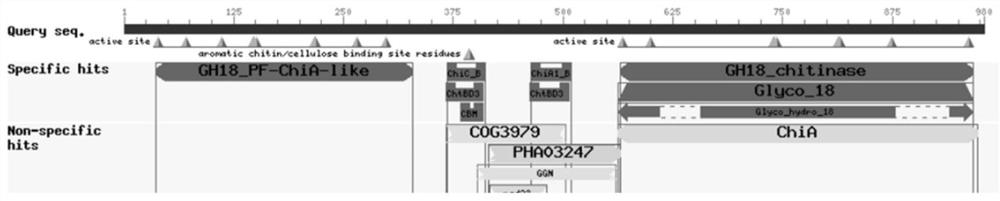

[0095] (1) Obtain chitinase cm Chi3 gene, its nucleotide sequence is shown in SEN ID NO:1.

[0096] (2) Design PCR amplification primers:

[0097] cm Chi3-F: 5'-GGGAATTCCATATGACCGAGATCGCCCCGTAC-3',

[0098] cm Chi3-R: 5'-CCGGAATTCGCGGCCGTTGCCCAGCAC-3' amplifies the full length of the gene;

[0099] (3) PCR amplification program:

[0100] Preheat at 95°C for 5 min; denature at 94°C for 45 s, anneal at 55°C for 45 s, extend at 72°C for 1.5 min, 30 cycles; extend at 72°C for 10 min; store at 4°C;

[0101] (4) Target gene after PCR amplification cm Chi3 and plasmid Pcold I both use restriction enzymes Nde I and EcoRI, incubate at 37°C for 1 hour. After digestion, the target gene is purified using a common DNA purification kit. After purification, it is stored at -20°C for later use. The recovery kit is recovered, and stored at -20°C after recovery;

[0102] (5) The...

Embodiment 3

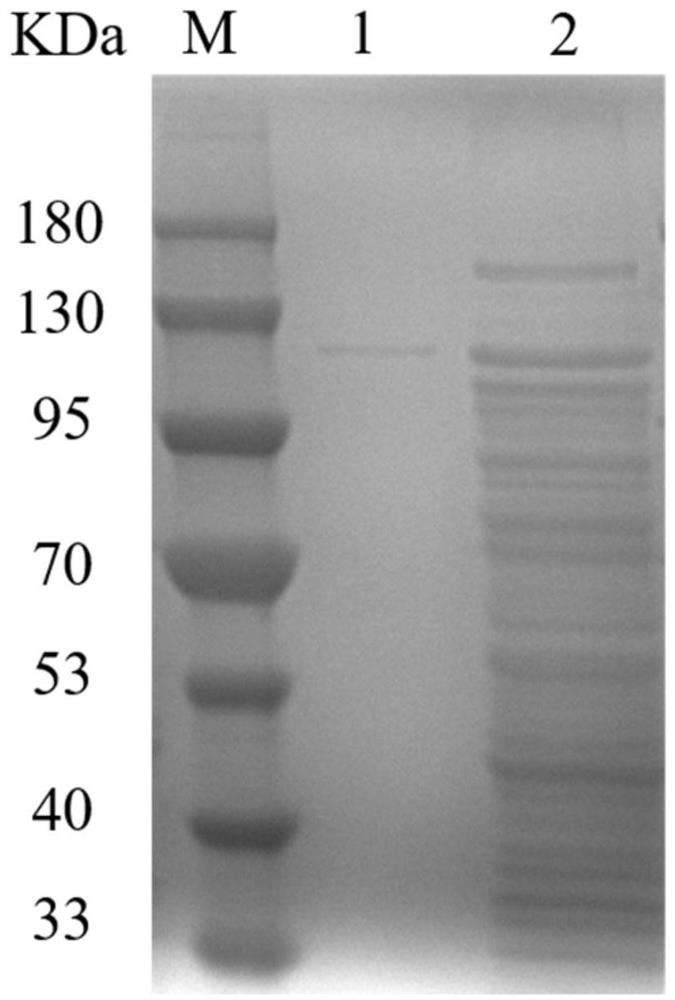

[0105] recombinant chitinase cm Expression and purification of Chi3

[0106] (1) After the preserved recombinant expression strain was revived on the plate, a single colony was picked and inoculated in 5 mL of LB liquid medium containing 0.05 g / LAmp, and cultured at 200 rpm for 8-10 h at 37°C. Transfer the activated bacterial solution to a 500 mL Erlenmeyer flask containing 100 mL LB medium (0.05g / L Amp) at an inoculum volume of 1% by volume, and cultivate to OD at 37°C and 200 rpm 600 When the temperature was 0.6-0.8, the inducer IPTG was added for induction, the induction temperature was 18°C, and the induction time was 16 h.

[0107] (2) After the cultivation, the cells were collected by centrifugation at 6000 rpm for 10 min at 4°C. After crushing using a sonicator, centrifuge at 8000 rpm for 20 min at 4°C to collect the supernatant. The supernatant is the crude enzyme solution containing recombinant chitinase, which is stored at 4°C for future use.

[0108] (3) The col...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com