Supercritical continuous synthesis method of low-cost fluorinated lithium iron phosphate positive electrode material

A technology of fluorinated lithium iron phosphate and positive electrode materials, applied in phosphorus compounds, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of high-purity iron sheet and iron powder, high production cost, complicated operation, etc., and achieve suitable Large-scale production, excellent performance, simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

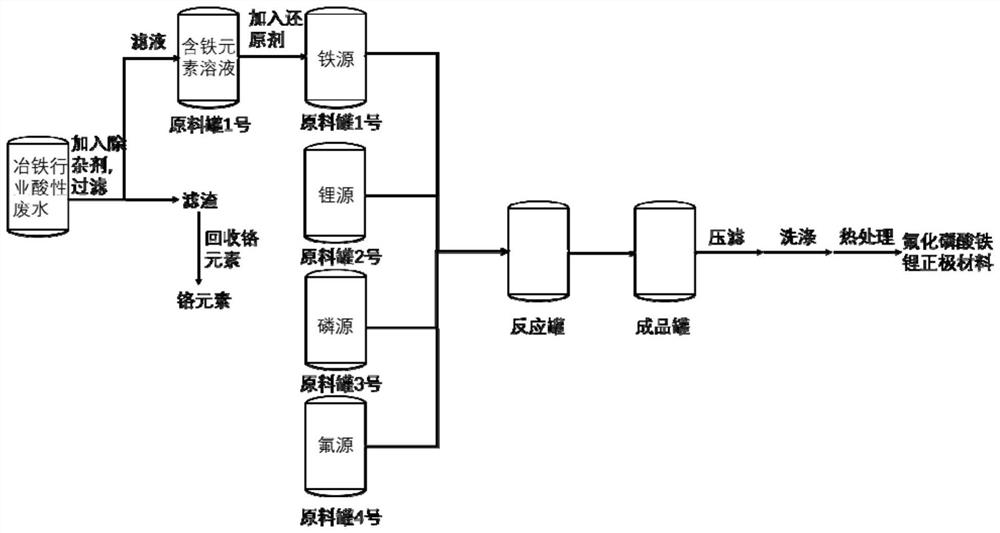

[0031] Embodiment 1 of the present invention is: a supercritical continuous synthesis method of a low-cost fluorinated lithium iron phosphate cathode material, such as figure 1 shown, including the following steps:

[0032] S1: Add 1% Na by mass to the pickling waste liquid in the iron smelting industry 2 CO 3 , the waste liquid containing Fe element can be obtained by filtration, the content of Fe element is tested to be 0.6mol / L, the waste liquid containing Fe element is injected into the raw material tank No. 1, and then the temperature of the raw material tank No. times ascorbic acid to get Fe 2+ solution, control the amount of residual acid after the reaction to ≤0.5%, and the pH is 3.0;

[0033] S2: Prepare lithium hydroxide (raw material tank No. 2), sodium phosphate (raw material tank No. 3) and ammonium fluoride solution (raw material tank No. 4) respectively, and then control raw material tank No. 2, raw material tank No. 3 and raw material tank respectively The ...

Embodiment 4

[0055] Embodiment 4 of the present invention is: a supercritical continuous synthesis method of a low-cost fluorinated lithium iron phosphate cathode material, comprising the following steps:

[0056] S1: Adding 2% NaHCO by mass to the pickling waste liquid of iron metallurgy industry 3 , 1% K 2 CO 3 , the waste liquid containing Fe ions can be obtained by filtering the pickling waste liquid in the iron smelting industry. The content of Fe element is tested to be 0.8mol / L. The waste liquid containing Fe element is injected into the No. 1 raw material tank, and then the temperature of the raw material tank No. 1 is controlled to 180°C , and adding 0.1 times of citric acid, 0.1 times of ascorbic acid and 0.1 times of aniline in the molar amount of Fe to obtain Fe 2+ solution, control the amount of residual acid after the reaction to ≤0.5%, and the pH is 4.0;

[0057] S2: Prepare lithium hydroxide (raw material tank No. 2), sodium phosphate (raw material tank No. 3) and ammoni...

Embodiment 5

[0063] Embodiment 5 of the present invention is: a supercritical continuous synthesis method of a low-cost fluorinated lithium iron phosphate cathode material, comprising the following steps:

[0064] S1: Adding 4% K by mass to the pickling waste liquid of iron metallurgy industry 2 CO 3 , the waste liquid containing Fe ions can be obtained by filtering the pickling waste liquid in the iron smelting industry. The Fe content is tested to be 1.0mol / L. The waste liquid containing Fe elements is injected into the No. 1 raw material tank, and then the temperature of the raw material tank No. 1 is controlled to 170°C , and adding citric acid with 0.25 times the molar amount of Fe to obtain Fe 2+ solution, control the amount of residual acid after the reaction to ≤0.5%, and the pH is 4.0;

[0065] S2: Prepare lithium hydroxide (raw material tank No. 2), sodium phosphate (raw material tank No. 3) and ammonium fluoride solution (raw material tank No. 4) respectively, and then control...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com