A kind of blood compatible polymer layer and preparation method thereof

A blood-compatibility, polymer layer technology, applied in coating, surgery, medical science, etc., can solve the problem that the hydrophobic property does not achieve the anti-fouling effect, and achieve excellent anti-erythrocyte adhesion performance and anti-platelet adhesion performance excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

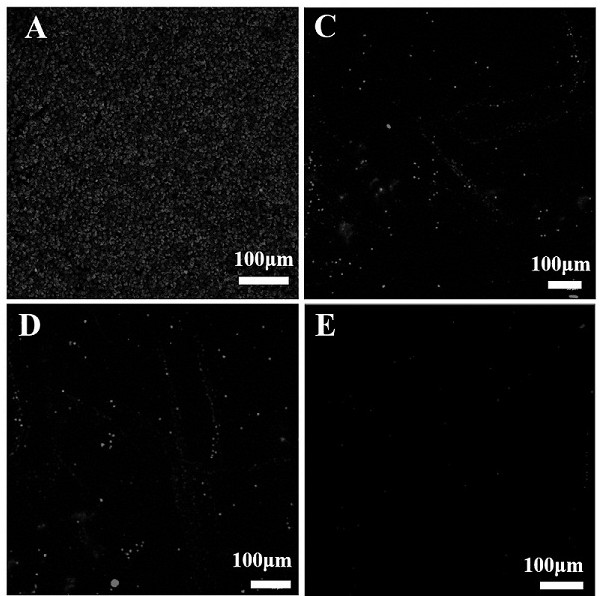

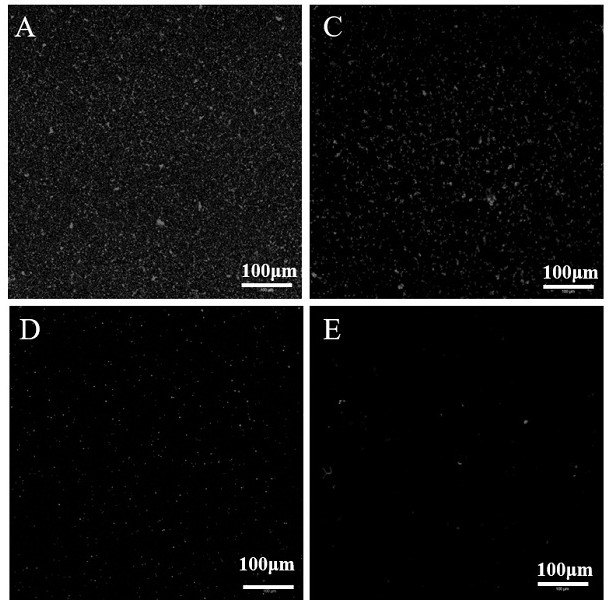

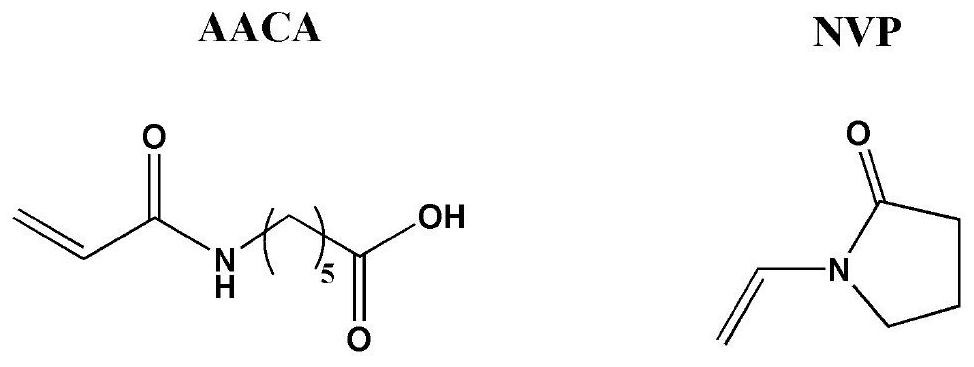

[0047] A method for preparing a blood-compatible polymer layer. Under the condition of ultraviolet light irradiation, a copolymerization reaction of 6-acrylamidohexanoic acid and N-vinylpyrrolidone is initiated on the surface of a silanized silicon wafer to prepare a grafted polymer layer. Hemocompatible polymer layers on silanized samples, such as Figure 9 shown, the specific steps are as follows:

[0048] (1) Place the silicon wafer in mixed solution I (a mixed solution of concentrated sulfuric acid and hydrogen peroxide, concentrated sulfuric acid is a sulfuric acid solution with a mass fraction of 90%, and hydrogen peroxide is a volume fraction of 30% hydrogen peroxide), and heated at 80 ° C 30min, after taking out, clean the surface with deionized water, and dry it by blowing high-purity nitrogen (purity 99.999%) to obtain a silicon wafer with hydroxylation on the surface, named Si-OH, and denoted as A; wherein concentrated sulfuric acid and hydrogen peroxide The volume...

Embodiment 2

[0067] A preparation method of a blood-compatible polymer layer, the specific steps are as follows:

[0068] (1) Place the substrate (ceramic) in mixed solution I (a mixed solution of concentrated sulfuric acid and hydrogen peroxide, concentrated sulfuric acid is a sulfuric acid solution with a mass fraction of 98%, and hydrogen peroxide is a volume fraction of 30% hydrogen peroxide), and at 78 ° C Under heating 30min, after taking out, clean the surface with deionized water, after adopting the mode of blowing high-purity nitrogen (purity 99.999%) to dry, obtain the substrate of surface hydroxylation; The volume ratio of vitriol oil and hydrogen peroxide in mixed solution I is 3: 1;

[0069] (2) silanizing the surface hydroxylated substrate obtained in step (1) to obtain a silanized substrate;

[0070] The specific silanization process is as follows: the surface hydroxylated substrate obtained in step (1) is placed in mixed solution II (silane coupling agent with double bonds...

Embodiment 3

[0075] A preparation method of a blood-compatible polymer layer, the specific steps are as follows:

[0076] (1) Place the substrate (glass) in mixed solution I (a mixed solution of concentrated sulfuric acid and hydrogen peroxide, concentrated sulfuric acid is a sulfuric acid solution with a mass fraction of 98%, and hydrogen peroxide is a volume fraction of 30% hydrogen peroxide), and at 79 ° C Under heating 32min, after taking out, clean the surface with deionized water, after adopting the mode of blowing high-purity nitrogen (purity 99.999%) to dry, obtain the substrate of surface hydroxylation; The volume ratio of vitriol oil and hydrogen peroxide in mixed solution I is 3: 1;

[0077] (2) silanizing the surface hydroxylated substrate obtained in step (1) to obtain a silanized substrate;

[0078] The specific silanization process is as follows: the surface hydroxylated substrate obtained in step (1) is placed in mixed solution II (silane coupling agent with double bonds, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com