Method for preparing optical waveguide micro-lens array and detecting optical performance

A micro-lens array, optical performance technology, applied in the testing of optical performance, optical instrument testing, optics, etc., can solve the problems of increasing the difficulty of the crystal cone processing, the improvement of optical crosstalk without in-depth analysis, etc., to achieve a short cycle and ensure uniformity. , the effect of accurate detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

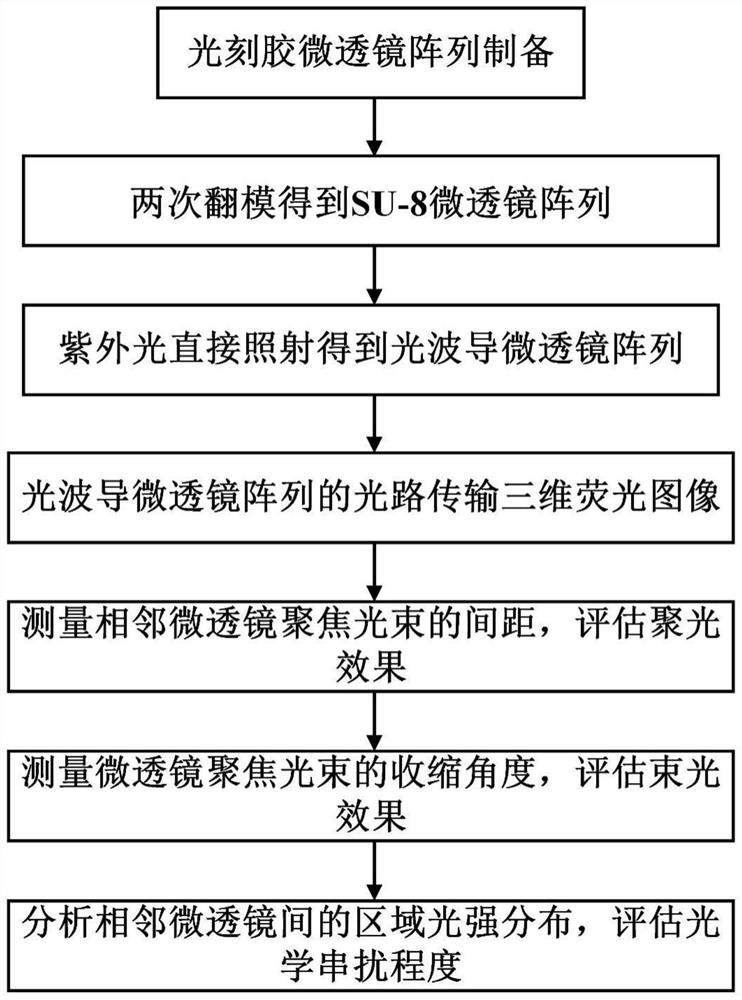

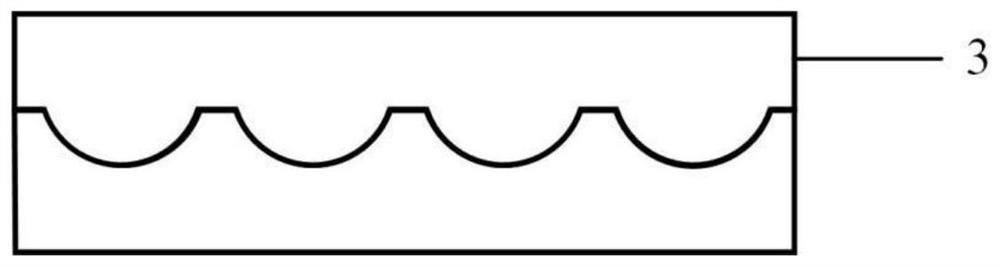

[0032] refer to figure 1 , a method for preparing an optical waveguide microlens array and detecting optical properties, comprising the following steps:

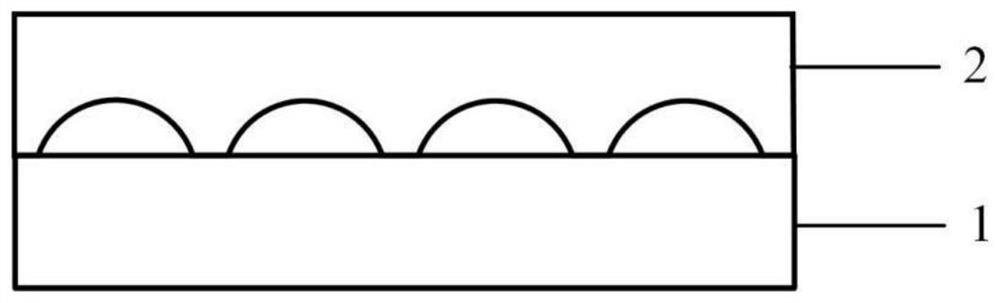

[0033] Step 1, prepare a photoresist microlens array on the glass substrate 1: wash the glass substrate with acetone, absolute ethanol, and deionized water for 10 minutes, and place the cleaned glass substrate 1 on a hot plate at 120°C Heating for 20 minutes; spin coating photoresist on the glass substrate 1, the photoresist is AZ4620, the spin coating parameters are 10s at a low speed of 500r / min, and 40s at a high speed of 3000r / min, to obtain a photoresist with a film thickness of about 10μm Adhesive film, after exposure under the photolithography machine, develop to obtain a columnar array, the exposure parameters are: the exposure power density is 10mW / cm 2 , the exposure time is 15s, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com