A strain of Bacillus tequila s1 with nitrogen-fixing function and its application in composting

A technology of Bacillus tequila and Bacillus, applied in the field of microorganisms, can solve the problems of inhibition of microbial population activity, actual utilization rate of less than 40%, decrease of population abundance, etc. The effect of strong nitrogen fixation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

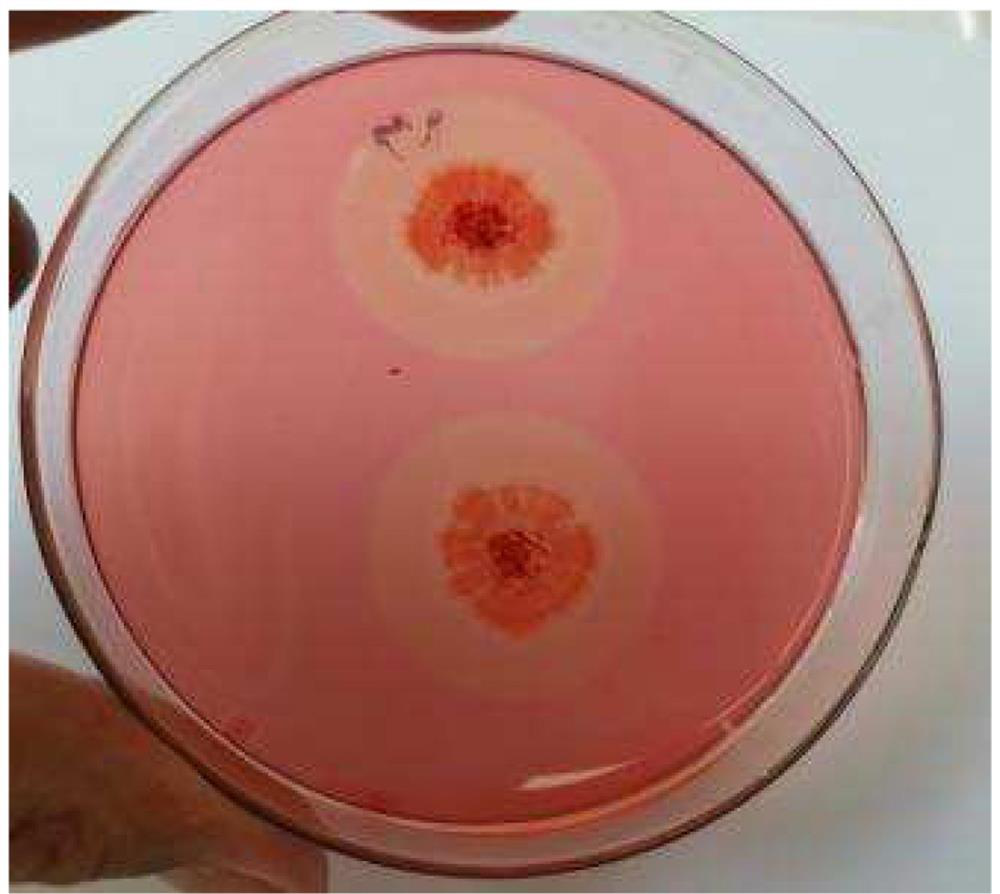

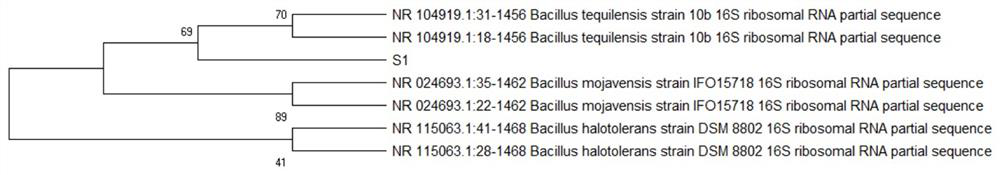

[0027] Embodiment 1: Isolation, screening and identification of bacterial strain S1

[0028] Isolation of strains: from the experimental base of Hubei Tiantou Biotechnology Co., Ltd. (Yaqueling "Vineyard" demonstration base) in Group 5 of Shuifumiao Village, Longquan Town, Yiling District, Yichang City, the surface layer of farmland with good ecology (2-5cm deep ) 5 cultivated soil samples. Equal amounts of soil samples were uniformly mixed in the laboratory, and 10 g of mixed soil samples were put into a conical flask filled with 90 mL of sterile water, shaken at 150 rpm at 37°C for 30 min to make a suspension. Take 10mL of the suspension, add it to a sterile test tube, and heat it in a boiling water bath for 10 minutes, then prepare the suspension with sterile water to a concentration of 10 -7 Take the dilution of 0.1mL of the dilution and spread it on the LB solid medium. Place the coated plate at 60°C and culture it. If it can grow and form a single colony within 3 days,...

Embodiment 2

[0034] Embodiment 2: the production of bacterial strain S1 fermented liquid

[0035] The bacterial strain Bacillus tequila strain S1 (CCTCC NO: M2020487) of Example 1 was inoculated into the glucose corn steep liquor dry powder liquid medium for fermentation and expansion. The fermentation condition of the 50L fermenter is pH 6.0-7.0, the fermentation temperature is 37°C, the stirring speed is 150-250rpm, the fermentation time is 36h, and the concentration of bacteria in the fermentation liquid is OD at the end of the fermentation 600 =12~15. The preparation method of the glucose corn steep liquor powder liquid medium used is: glucose 1.5g / L, corn steep liquor dry powder 4g / L, adjust the initial pH value to 7.5, sterilize at 115°C for 30min, and the volume of the fermentation medium is 30L. If feeding is required during the fermentation process, the preparation method of the feeding medium is as follows: glucose 15g / L, corn steep liquor powder 40g / L, adjust the initial pH val...

Embodiment 3

[0036] Embodiment 3: composting experiment

[0037] The yeast waste liquid concentrate (provided by Angel Yeast Co., Ltd., specifically the fermentation waste liquid produced by yeast production) was obtained after evaporation and concentration. Its properties were brown viscous liquid. 35.6%, total nitrogen 2.6%, ammoniacal nitrogen 0.8%, P 2 o 5 0.5%, K 2 (6.5%, pH 5.6) and rice husk are initially mixed according to mass ratio 0.45:0.55, until the flow of yeast waste liquid concentrate is not observed, insert the bacterial strain Bacillus tequila strain S1 of embodiment 2 according to 0.5% of the total mass of compost raw materials The fermented liquid is replenished with water until the moisture content of the heap is 50% to 55%. After mixing evenly, the heap grows into a nearly cubic heap (abbreviation: experimental group, the same below) with a length of 10 meters, a width of 4 meters, and a height of 1.5 meters. Use a forklift to turn the compost during the compostin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com