Vanadate electrode material as well as preparation method and application thereof

An electrode material and vanadate technology, applied in the field of electrochemistry, can solve the problems that the interlayer spacing is difficult to meet the free movement of sodium ions, the material cannot be fully redox reaction, and the sodium storage capacity cannot be fully released, etc., and achieve stable charge-discharge cycles. performance, good electrical conductivity and structural stability, the effect of improving the discharge specific capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] (1) Dissolve 4mmol sodium orthovanadate in 80mL water to obtain a sodium vanadate solution with a vanadate ion concentration of 0.05mol / L, add acetic acid dropwise to adjust the pH of the solution to 2.0, and carry out prepolymerization at 80°C for 60 Minutes to form polyvanadate ion groups;

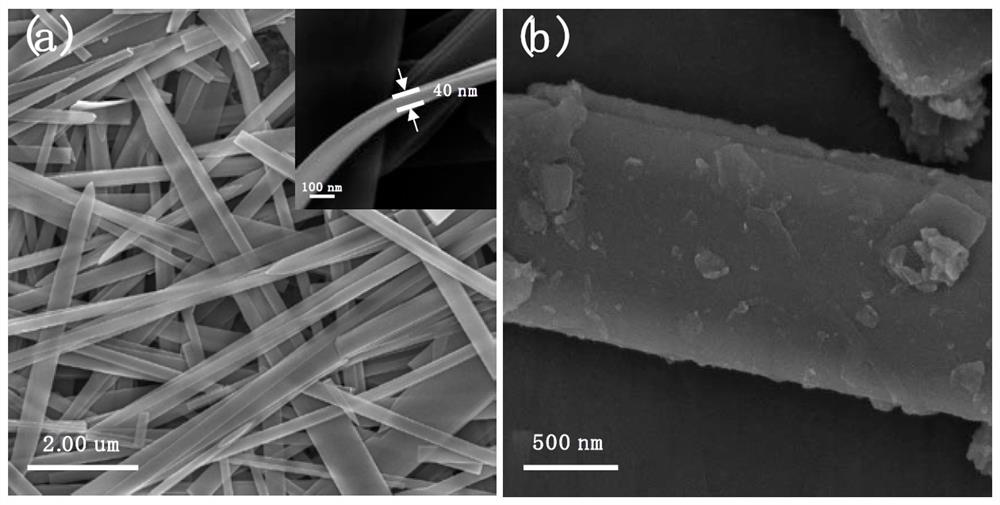

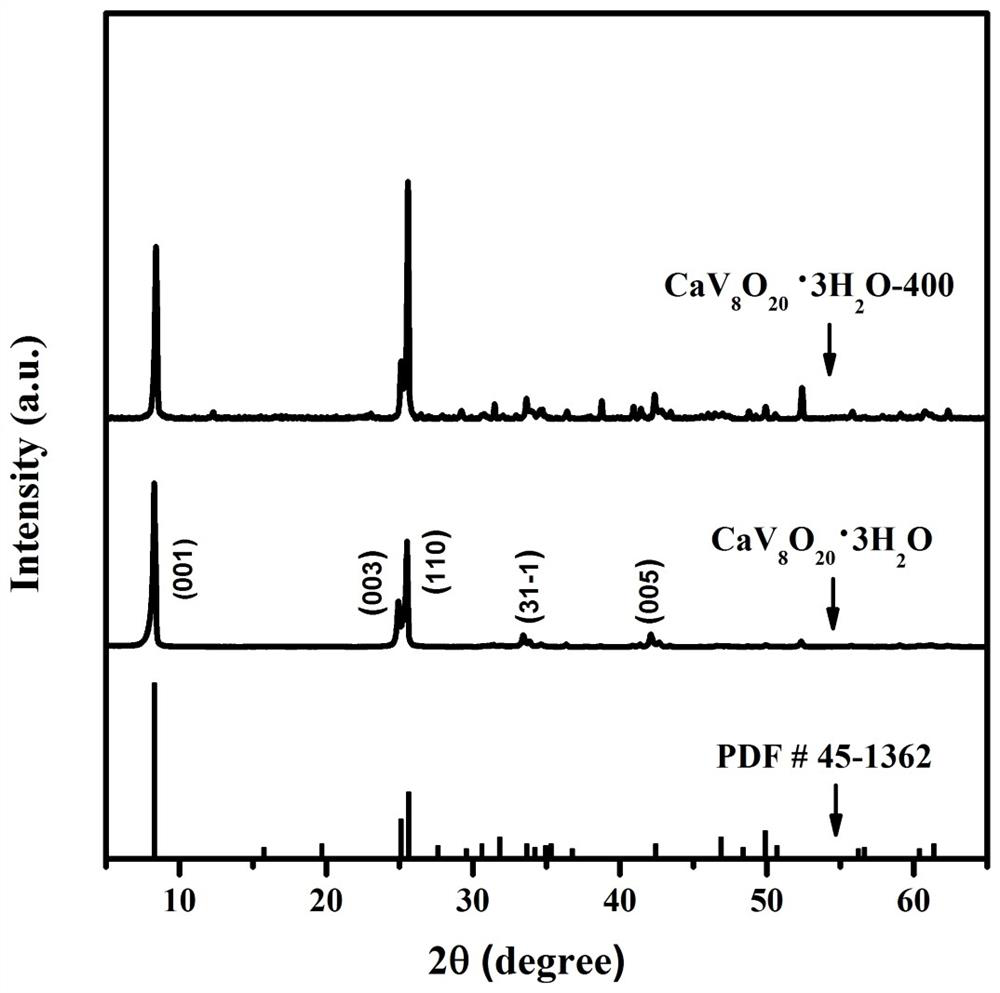

[0046] (2) Add 4mmol of calcium chloride hydrate and stir to dissolve fully, carry out hydrothermal reaction in a high-temperature reactor at 220°C for 24 hours, after the reaction is completed, after the reaction is completed, after alternating centrifugal ultrasonic washing with water and alcohol, dry at 70°C to obtain nanobelts Calcium vanadate with structure;

[0047] (3) Disperse 0.1g of calcium vanadate obtained in step (2) and 0.1g of melamine monomer in 100mL of deionized water, stir until a uniform suspension is formed, and then add 1mL of formaldehyde solution (37-40 wt% ) and 0.2mL of acetic acid (analytically pure), polymerized at 50°C for 12 hours. After the reaction...

Embodiment 2

[0049] Example 2: The difference from Example 1 is that 6 mmol of sodium citrate is added while adding calcium chloride hydrate in step (2), and the rest of the implementation steps and process conditions are the same, and finally carbon-coated nanosheets are obtained calcium vanadate electrode material.

Embodiment 3

[0051] (1) Dissolve 1.6mmol sodium orthovanadate in 80mL water to obtain a sodium vanadate solution with a vanadate ion concentration of 0.02mol / L, add acetic acid dropwise to adjust the pH of the solution to 3.0, and perform prepolymerization at 60°C 30 minutes to form polyvanadate ion groups;

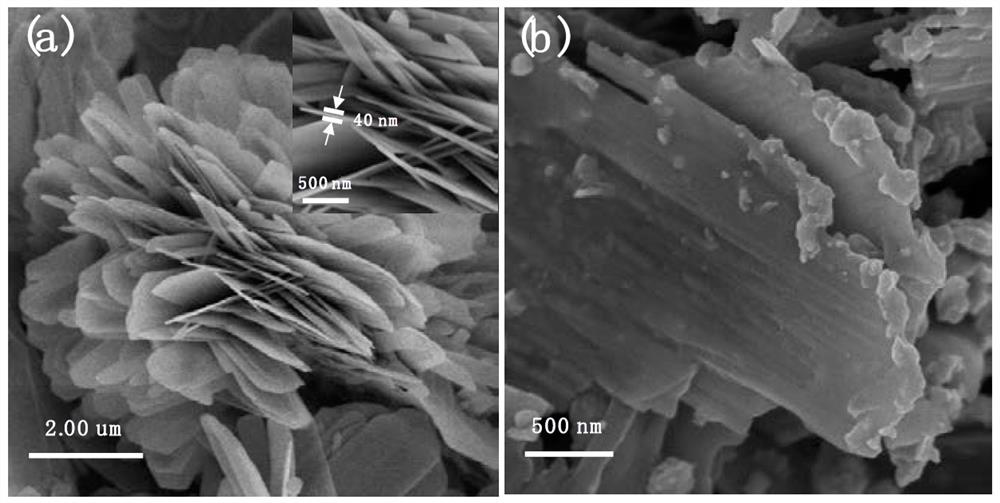

[0052] (2) Add 3.2mmol of barium chloride hydrate and fully stir to dissolve, carry out hydrothermal reaction in a high-temperature reactor at 250°C for 12 hours. After the reaction, after the reaction is completed, it is washed with water and alcohol alternately, centrifugally and ultrasonically, and dried at 70°C to obtain nano Barium vanadate with ribbon structure;

[0053] (3) Disperse 0.1 g of barium vanadate obtained in step (2) and 0.1 g of resorcinol monomer in 100 mL of deionized water, stir until a uniform suspension is formed, then add 1 mL of formaldehyde solution (37-40 wt%) and 0.2mL of ammonia water (25-28wt%), polymerized at 30°C for 18 hours, after the reaction, afte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com