Magnesium-doped zinc oxide magnetron sputtering target material and preparation method thereof

A technology of magnetron sputtering and zinc oxide, which is applied in the direction of sputtering coating, metal material coating process, vacuum evaporation coating, etc., can solve the problems of high equipment requirements, increased density, high threshold of use, etc., and achieve favorable Effects of industrialized production, reduction of preparation cost and improvement of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

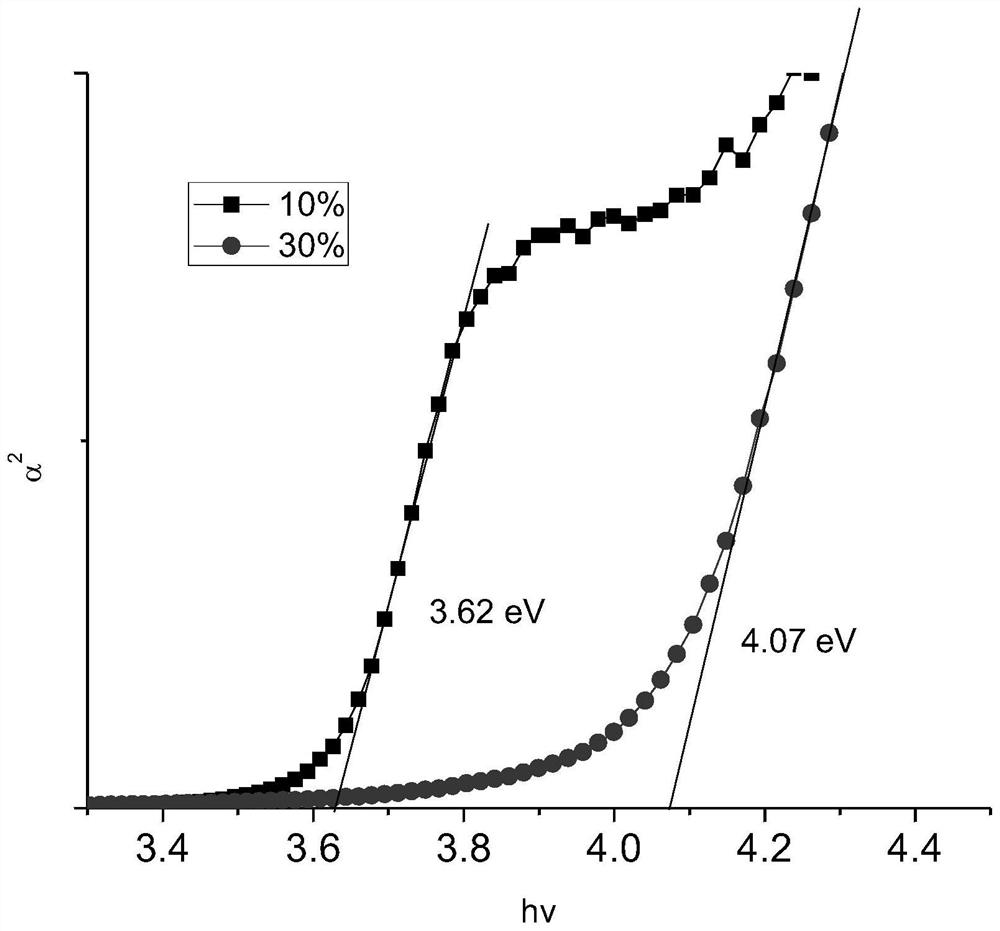

Embodiment 1

[0038] (1) Weigh high-purity zinc oxide powder, high-purity magnesium oxide powder and the third oxide powder and mix to form an atomic ratio mixture xMgO (1-x-y)ZnO yMOn, where x=0.1, y =0.05; configure ethanol mixed solution, wherein the deionized water content is 10wt%; according to the mass ratio of mixed solution and powder is 3:1, mix the powder and pour it into the mixed solution to form a slurry;

[0039] (2) Place the slurry in a planetary ball mill and mix it for 15 hours, where the ratio of balls to materials is 5:1; take out the slurry after ball milling, dry it at 80°C, and collect the dried powder , grind, and pass through an 80-mesh sieve to obtain a powder for molding;

[0040] (3) The obtained powder is placed in a rubber sleeve mold, and molded in a cold isostatic press under the conditions of 160MPa and pressure holding for 30s to form a green body;

[0041] (4) Put the formed body into a box-type resistance furnace, raise the temperature to the first sinte...

Embodiment 2

[0044] (1) Weigh high-purity zinc oxide powder, high-purity magnesium oxide powder and the third oxide powder and mix to form an atomic ratio mixture xMgO·(1-x-y)ZnO·yMOn, where x=0.2, y =0.01; configure ethanol mixed solution, wherein the deionized water content is 20wt%; according to the mass ratio of mixed solution and powder is 3:1, mix the powder and pour it into the mixed solution to form a slurry;

[0045] (2) Place the slurry in a planetary ball mill and mix it for 15 hours, where the ratio of balls to materials is 5:1; take out the slurry after ball milling, dry it at 80°C, and collect the dried powder , grind, and pass through an 80-mesh sieve to obtain a powder for molding;

[0046] (3) The obtained powder is placed in a rubber sleeve mold, and molded in a cold isostatic press under the conditions of 160MPa and pressure holding for 30s to form a green body;

[0047] (4) Put the formed body into a box-type resistance furnace, raise the temperature to the first sinte...

Embodiment 3

[0050] (1) Weigh high-purity zinc oxide powder, high-purity magnesium oxide powder and the third oxide powder and mix to form an atomic ratio mixture xMgO (1-x-y)ZnO yMOn, where x=0.3, y =0.05; configure ethanol mixed solution, wherein the deionized water content is 10wt%; according to the mass ratio of mixed solution and powder is 3:1, mix the powder and pour it into the mixed solution to form a slurry;

[0051] (2) Place the slurry in a planetary ball mill and mix it for 15 hours, where the ratio of balls to materials is 5:1; take out the slurry after ball milling, dry it at 80°C, and collect the dried powder , grind, and pass through an 80-mesh sieve to obtain a powder for molding;

[0052] (3) The obtained powder is placed in a rubber sleeve mold, and molded in a cold isostatic press under the conditions of 160MPa and pressure holding for 30s to form a green body;

[0053] (4) Put the formed body into a box-type resistance furnace, raise the temperature to the first step ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com